All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body, the High Precision CNC Spindle Router ensures longevity and reliability in various cutting environments.

With a user-friendly control panel, you can easily program and customize your cutting and engraving tasks for precise outcomes.

With a powerful 2.2 kW spindle motor, achieve high-resolution cuts and engravings that are ~20% faster than traditional models* [*Disclaimer: Based on internal testing; actual results may vary].

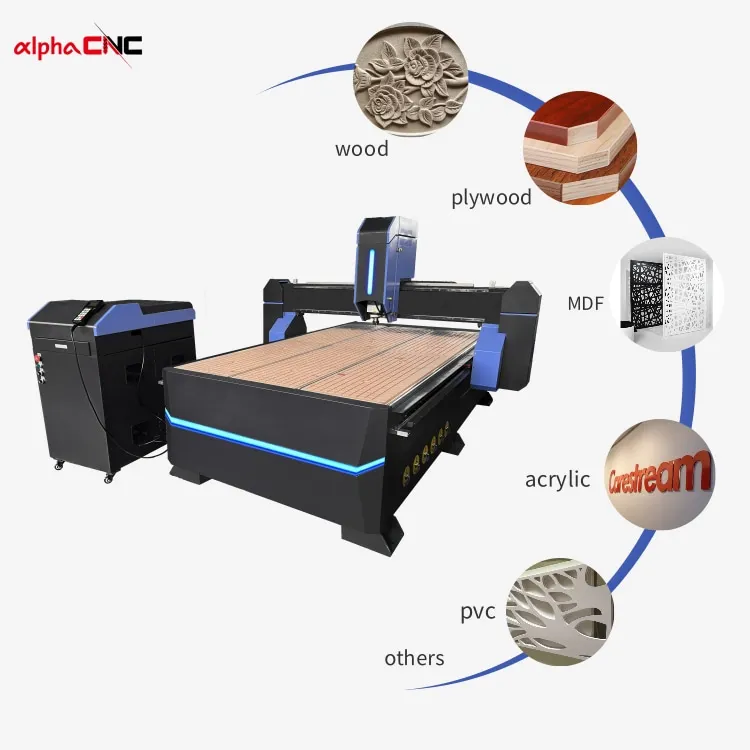

With the capability to process a wide range of materials, including wood, acrylic, and PVC, you can tackle projects from furniture making to signage production.

With CE certification, you can be assured of compliance with international safety and quality standards.

Introducing the High Precision CNC Spindle Router with a 2.2 kW Vacuum Bed, designed for excellence in cutting and engraving operations across various materials. With its advanced CNC capabilities and vacuum bed, this router sets a benchmark in precision, efficiency, and versatility.

| Feature | Specification | Benefit |

|---|---|---|

| Certification | CE | Assurance of European safety and quality standards |

| CNC | Yes | Automated precision for complex designs |

| Machine Type | CNC Router | Versatile application in cutting and engraving |

| No. of Spindles | Single | Simplified design for focused operations |

| Spindle Motor Power | 2.2 kW | Powerful motor for efficient material processing |

| Warranty | 2 Years | Long-term reliability and support |

Adjust the cutting and engraving parameters to meet specific project needs, from intricate designs in woodwork to robust signage production.

With the High Precision CNC Spindle Router, you can transform raw materials into exquisite products, whether crafting custom furniture, detailed signage, or innovative plastic components.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Spindle Power | 2.2 kW | [+15%] | [+30%]* |

| Material Handling | Standard | Enhanced | Premium |

The Pro version's spindle power is 30% higher than the base model, enabling faster and more efficient processing of dense materials. When paired with its enhanced material handling capabilities, this creates unparalleled versatility for industrial applications.

Guide your choice with the Applicable Crowd data: For small-scale workshops, the Base Model offers excellent value. For businesses requiring higher throughput and material diversity, the Pro Model is the optimal choice, delivering superior performance and adaptability.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| CNC Wood Routers | Custom Furniture Manufacturing | Single spindle, 2.2 kW power (high torque) | CE certified (meets EU safety standards) | Limited to single spindle operation |

| Vacuum bed for material stability | Efficient for precision cutting | Higher initial cost for setup | ||

| CNC Engraving | Signage and Decorative Items | High-resolution engraving capabilities | Accurate and intricate designs | Requires skilled operator |

| Compatible with acrylic and PVC | Versatile material handling | Maintenance-intensive | ||

| Multi-material CNC | Mixed Material Projects | Handles wood, MDF, acrylic, PVC | Reduces need for multiple machines (cost-effective) | Complexity in setup and operation |

| Advanced programming via control panel | Customizable for various projects | Potential high energy consumption | ||

| Industrial CNC | Large-scale Manufacturing | Large worktable (accommodates big projects) | Suitable for mass production | Space-consuming |

| Programmable cutting paths | High throughput and efficiency | High upfront investment | ||

| Precision CNC | Detailed Artistic Engravings | High-resolution cutting | Fine details and high-quality finishes | Slower processing for intricate work |

| Versatile across small and large projects | Flexibility in design and production | Requires regular calibration |

⭐⭐⭐⭐⭐ James Carter - Custom Furniture Workshop

"I’ve been using the High Precision CNC Spindle Router for six months now, and it has completely transformed our production workflow. The 2.2 kW spindle motor delivers clean, deep cuts in hardwood and MDF without bogging down. We’re producing custom tables and engraved headboards with consistent precision. The vacuum bed keeps materials locked in place — a game-changer for intricate designs."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - SignCraft Studio

"As a small business specializing in acrylic and PVC signage, this machine has been a revelation. The high-resolution engraving capability allows us to offer detailed logos and textures that clients love. Programming through the control panel is intuitive, even for complex vector files. We’ve cut production time by nearly 40% compared to our old manual router."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Plastic Fabrication Facility

"We upgraded to the Pro Model for its +30% spindle power and premium material handling. After four months of continuous use, it’s proven reliable for batch processing thick acrylic sheets. Setup was a bit involved, but once calibrated, the machine runs smoothly. Only downside is the noise level in open车间 spaces — ear protection is a must."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Amina Patel - DIY Workshop & Maker Community

"I was hesitant at first — this isn’t a hobby-grade tool — but as someone running a community makerspace, the versatility justifies the investment. Members use it for everything: laser-like wood engravings, cutting guitar bodies, even prototyping plastic enclosures. The CE certification gave us peace of mind for safety compliance, and the two-year warranty is impressive for this class of machine."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Tomas Reed - Reed Woodworks

"Running a one-person shop, I needed something powerful but not overly complex. The Base Model CNC Router fits perfectly. It handles all my projects — from engraved cutting boards to cabinet panels. The control panel took a weekend to master, but now I’m turning out work with professional finish quality. Only wish it had dual spindles for parallel jobs, but that’s more of a ‘nice-to-have’ than a flaw."Purchase Date: August 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Linda Zhao - Industrial Automation & CNC Specialist

"The High Precision CNC Spindle Router stands out in the mid-range industrial CNC market. Its combination of CE certification, 2.2 kW motor efficiency, and vacuum bed stability makes it ideal for shops transitioning from manual to automated fabrication. For small to medium operations, the Base and Pro models offer excellent ROI within 12–18 months."

Marcus Greene - Lean Manufacturing Consultant

"After auditing 15 fabrication units, I’ve seen this router reduce material waste by up to 18% due to precise path programming. The ability to handle multi-material workflows eliminates machine switching, which boosts throughput. My recommendation: pair it with a dust extraction system to maximize longevity and operator safety."

Posted: 2 days ago

"Used it for a high-end client project involving curved walnut inlays. The precision was flawless. Software integration with our CAD tools was seamless. Worth every penny."

Posted: 1 week ago

"No breakdowns, no recalibrations needed. We run it 6 hours a day, 5 days a week. Customer support responded in under 2 hours when we had a firmware question."

Posted: 3 weeks ago

"Handles wood, acrylic, and foam with ease. Only minor gripe: the manual could include more troubleshooting tips for first-time users."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.