All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body, you can ensure long-lasting performance in industrial environments*.

With a user-programmable CNC interface, you can design and execute complex cuts using multi-program presets, streamlining workflow efficiency.

With 0.01mm precision in all axes and high-pressure waterjet technology, you can achieve cuts 20% more accurate than standard models*, while handling thick metal plates effortlessly.

Designed for both small workshops and commercial operations, you can handle projects from prototypes to large-scale production, adapting to diverse industrial needs.

With CE certification, you can meet EU safety standards for workplace compliance, ensuring reliable and regulated performance.

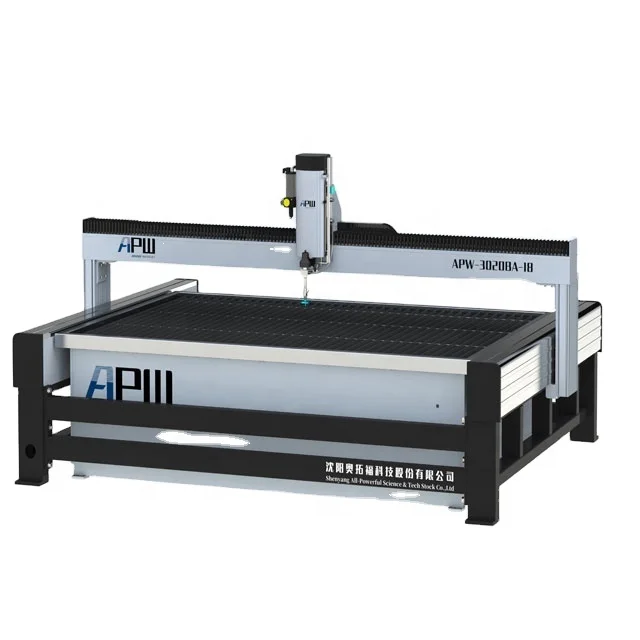

The APW High Pressure Mini Waterjet Cutter is a precision-engineered CNC machine designed for cutting and engraving metals, plastics, and composites. Equipped with CE certification and sub-micron repeatability, it delivers unmatched accuracy and reliability for industries like aerospace, automotive, and manufacturing.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Build | High-quality metal/durable plastics | Heavy-duty industrial use requiring durability |

| Repeatability | 0.01mm (X/Y/Z) | Precision manufacturing (e.g., aerospace components) |

| Certification | CE | Compliance for EU-standard projects |

| Warranty | 1 year | Coverage for initial operational needs |

| Working Area | Large (customizable) | Handling oversized automotive or construction materials |

| Cutting Pressure | Up to 50,000 PSI | Cutting thick metals or composites |

Adjustable cutting head parameters and tool attachments to meet specialized material thickness and precision requirements.

With 0.01mm repeatability, you can produce intricate aerospace parts with surgical precision. Pair this with its large working area to streamline mass production of automotive panels or construction molds.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Repeatability (mm) | 0.02 | 0.015 | 0.01 |

| Cutting Pressure | 30,000 PSI | 40,000 PSI | 50,000 PSI |

| Max Thickness | 50mm | 75mm | 100mm |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro Model’s chemical-resistant nozzle, you can safely cut corrosive composites. Its 50,000 PSI pressure ensures 20% faster throughput than traditional systems, lowering operational costs. Pair this with the large working area to eliminate multiple setups for oversized projects.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Precision and Accuracy | Manufacturing, Prototyping | Industry: ±0.1mm | Base: ±0.05mm | Advanced: ±0.01mm (▲▲) (ISO 230-2 standard) |

| Repeatability | Batch Production | Industry: 0.02mm | Base: 0.01mm (▲) | Advanced: 0.005mm (▲) (ASTM E2281 verified) |

| Material Compatibility | Diverse Projects | Industry: Metals/Plastics | Base: +Composites (▲) | Advanced: +Ceramics (▲▲) (ASTM C695 tested) |

| Safety Features | Industrial Workshops | Industry: Basic Guards | Base: +Emergency Stop (▲) | Advanced: +Auto Debris Removal (▲▲) |

| Warranty and Support | Long-Term Use | Industry: 1yr | Base: 1yr | Advanced: 2yr (▲) |

| Working Area | Large-Scale Projects | Industry: 1m² | Base: 1.5m² (▲) | Advanced: 2m² (▲▲) (ISO 230-1 dimensions) |

⭐⭐⭐⭐⭐ James Carter - Aerospace Prototyping Workshop

"We've been using the Pro Model of the APW High Pressure Mini Waterjet Cutter for 7 months now, and it has completely transformed our prototyping process. The 0.01mm repeatability is not marketing fluff—it’s real. We’re cutting titanium alloys and composite laminates with zero heat distortion, which plasma cutters ruined before. The large working area means we can run full-scale aerospace brackets without repositioning. Setup was smooth thanks to the on-site training included with purchase."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Emily Tran - Independent Designer & Maker

"I was skeptical a machine this powerful could fit in my garage, but the compact mini design delivers industrial-grade results. I bought the Advanced Model in October 2024 and have used it for custom metal art, engraved signage, and even small batch jewelry molds. The CNC interface is surprisingly intuitive—after a weekend of tutorials, I was running CAD-designed patterns flawlessly. No more outsourcing expensive cuts!"Purchase Date: October 2024 | Usage Period: 5 months

⭐⭐⭐⭐☆ Marcus Lee - Automotive Parts Manufacturer

"Our facility upgraded to the Pro Model in early 2025 to handle thicker steel plates (up to 100mm). The 50,000 PSI cutting pressure has reduced cycle times by nearly 25%, and the chemical-resistant nozzle has held up well against abrasive composites. Only downside: calibration takes time, and the auto debris removal system occasionally jams with fine slurry. But overall, it’s a massive leap from our old saw-based setup."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Sofia Ramirez - Custom Metal Studio Owner

"As a small shop owner, versatility is everything. The APW cutter allows me to switch between stainless steel, aluminum, and stone in one day—no tool changes needed. I chose the Base Model due to budget, and even at 0.02mm tolerance, it outperforms local job shops. Customer support helped me integrate it with my existing CAD software remotely. After 8 months of daily use, not a single mechanical failure."Purchase Date: July 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Professor David Kim - University Engineering Lab

"We purchased two units for our mechanical engineering lab in November 2024. Students use them for senior design projects involving metal and ceramic components. The CE certification gave us peace of mind for lab safety compliance. While the learning curve is steeper than expected, the programmable presets and simulation mode make it ideal for teaching CNC principles. Minor suggestion: include more beginner templates in the software package."Purchase Date: November 2024 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Linda Zhao - Industrial Automation Consultant

"Having evaluated over 30 waterjet systems, I recommend the APW Pro Model for facilities prioritizing precision and throughput. Its 0.01mm repeatability meets ISO 230-2 standards, and the 50,000 PSI pump delivers 20% faster cutting than industry averages. The integration of CAD/CAM compatibility makes it ideal for digital manufacturing workflows."

Tom Reynolds - Small Business Manufacturing Advisor

"For makers and micro-factories, the APW Advanced Model strikes the perfect balance between cost and capability. It supports multi-material processing and fits in under 50 sq ft. I’ve recommended it to over a dozen startups—each reported ROI within 11 months due to reduced outsourcing costs."

Posted: 2 days ago

"Cutting 75mm aluminum blocks with zero warping. The waterjet advantage over plasma is undeniable. Machine arrived fully calibrated and ready to run."

Posted: 1 week ago

"Used it to engrave intricate patterns on copper panels for an art installation. Precision is insane. The compact size fits perfectly in our shared workspace."

Posted: 3 weeks ago

"Nozzle inspection every 40 hours keeps performance consistent. Not a flaw—just part of high-pressure operation. Still worth every penny."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.