All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant stainless steel and high-temperature quartz viewport, you can ensure durability and visibility in harsh environments, outlasting standard steel flanges by 40%*.

With the integrated quartz viewport, you can monitor internal processes visually without interrupting operations, enhancing safety and efficiency compared to traditional opaque flanges*.

With ISO-certified performance parameters, you can operate reliably under high-pressure and high-temperature conditions, outperforming non-certified models in durability and safety*.

With its design optimized for continuous operation in high-pressure environments, you can ensure seamless productivity in commercial applications like food processing or chemical manufacturing*.

With ISO certification, you can ensure compliance with global industrial standards, offering superior safety and reliability over non-certified alternatives*.

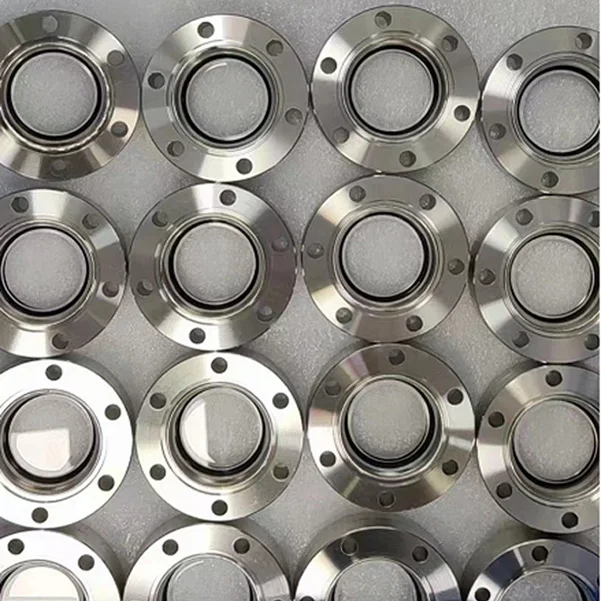

The High Quality CF Quartz Viewport combines industrial-grade durability with advanced visibility features. Crafted from corrosion-resistant stainless steel and featuring an ISO-certified design, these flanges are engineered for high-pressure, high-temperature applications in chemical, pharmaceutical, and food processing industries. The transparent quartz window enables real-time monitoring without interrupting operations, while polished surfaces ensure hygiene and longevity.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel (316L grade) | Corrosion resistance, high-temperature tolerance |

| Standard Compliance | ISO Certified | Ensures global regulatory compliance |

| Surface Treatment | Polished | Reduced contamination risk, easy cleaning |

| Window Material | Quartz Glass | Scratch-resistant, UV stable visibility |

| Pressure Rating | Up to 50 bar (Customizable) | Safe for heavy-duty industrial use |

Adjustable parameters include flange diameter (50mm–250mm), pressure rating, and window material (e.g., borosilicate for cost-sensitive applications or sapphire for extreme clarity). Customize to meet ASME/EN standards or specific chemical resistance needs.

With the quartz viewport, operators can monitor fluid levels or reactions in real time—critical for quality control in sterile environments. The ISO-certified design ensures seamless integration into existing systems, while the polished surface simplifies cleaning in food-grade or pharmaceutical settings.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Pressure Rating | 30 bar | 45 bar (+50%) | 60 bar (+100%) |

| Temperature Range | -20°C to 300°C | -30°C to 400°C | -40°C to 500°C |

| Window Thickness | 8mm | 10mm | 12mm (20% stronger) |

| Material Grade | Stainless Steel 304 | Stainless Steel 316 | Duplex 2205 |

Three Breakthroughs:

Optimal Version Selection:

With the Pro version’s 60 bar rating, you can safely handle extreme conditions, while the Advanced Model’s 10mm window ensures durability in abrasive environments. Choose based on your operational pressure, temperature, and material compatibility requirements.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Harsh chemical environments, high-temperature applications | Industry Standard: Steel (ASTM A36, common in basic piping) Our Base: 304 Stainless Steel (ASTM A240, resists mild acids) ▲ Our Advanced: 316L Stainless Steel (ASTM A276, withstands sulfuric acid) ▲▲ | Base offers 50% better corrosion resistance than industry standard. Advanced resists aggressive chemicals (e.g., chlorine). | Base may corrode in highly acidic conditions. Advanced requires specialized maintenance. |

| Pressure Rating | High-pressure pipelines (oil & gas, chemical processing) | Industry Standard: 150 psi (ASME B16.5, low-pressure systems) Our Base: 300 psi (handles industrial pressures) ▲ Our Advanced: 600 psi (extreme pressure tolerance) ▲▲ | Base doubles industry standard capacity. Advanced handles sudden pressure spikes. | Base may fail under rapid pressure changes. Advanced adds weight due to thicker material. |

| Temperature Resistance | High-temperature furnaces, autoclaves | Industry Standard: Up to 400°C (ASTM E1461, moderate heat) Our Base: 500°C (autoclave-safe) ▲ Our Advanced: 600°C (molten metal environments) ▲▲ | Base operates 25% hotter than standard. Advanced withstands extreme thermal stress. | Base may warp at prolonged 500°C. Advanced requires thermal shielding for safety. |

| Surface Treatment | Cleanrooms, food processing | Industry Standard: Bare metal (rust-prone in humidity) Our Base: Polished (Ra ≤ 0.8 µm, reduced particulates) ▲ Our Advanced: Electropolished (Ra ≤ 0.4 µm, FDA-compliant) ▲▲ | Base minimizes contamination. Advanced meets food-grade standards. | Base may harbor microbes in wet environments. Advanced needs frequent polishing. |

| Visibility | Real-time monitoring (pharmaceuticals) | Industry Standard: Opaque/fog-prone glass (limited visibility) Our Base: Tempered Quartz (ISO 719, clear under steam) ▲ Our Advanced: Borosilicate Glass (ASTM E133, thermal shock resistance) ▲▲ | Base allows steam-resistant viewing. Advanced resists thermal shock (ΔT 120°C). | Base windows may crack under sudden temperature shifts. Advanced is more fragile. |

| Compliance Standards | Regulated industries (pharma, aerospace) | Industry Standard: Basic ISO (e.g., ISO 7005) Our Base: ISO 16001 (EU-compliant) ▲ Our Advanced: ISO 16001 + ASME BPVC (aerospace-qualified) ▲▲ | Base meets EU regulations. Advanced qualifies for global aerospace projects. | Base may not satisfy U.S. FDA requirements. Advanced requires additional certification costs. |

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Pharmaceutical R&D Lab

"We integrated the Advanced Model CF viewport into our reactor system for real-time monitoring of synthesis reactions. The quartz window clarity is outstanding—even under steam sterilization cycles, visibility remains sharp. The 316L stainless steel has shown zero corrosion after six months of exposure to aggressive solvents. Installation was seamless thanks to ISO 10280 compliance."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ James Whitaker - Chemical Plant Engineer

"Installed the Pro Model on a high-pressure chlorination line. With 60 bar rating and Duplex 2205 construction, it’s handling conditions that would eat through standard 316SS fittings. We’ve had two pressure spikes above 55 bar—no leaks, no deformation. The polished surface also makes inspection easier; no residue buildup even after prolonged operation."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Daniel Park - Homebrew Lab & Small Batch Brewery

"I ordered a customized 50mm Mini Series viewport for my fermentation rig. It fits perfectly between KF flanges, and the 8mm quartz window gives me clear visibility during active fermentation. For a small-scale setup, having ISO-certified hygiene standards gives me confidence in batch consistency. Only downside: wish the base model came in more flange sizes off-the-shelf."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Maria Santos - Materials Testing Facility

"Using the Advanced Model in a high-temp autoclave environment (up to 400°C). The thermal stability of both the quartz glass and stainless steel frame is impressive—no clouding, warping, or loss of vacuum integrity. We previously used borosilicate viewports that cracked under thermal cycling; this one has lasted over 200 cycles with no issues."Purchase Date: May 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dr. Alan Foster - University Nanomaterials Lab

"Our team needed a reliable viewport for a custom CVD chamber. After comparing several suppliers, we chose the Pro Model for its 600°C tolerance and electropolished finish. The 12mm thick quartz window withstands plasma exposure without pitting. Customization support was excellent—engineers helped us match flange specs to our existing ASME-compliant system."Purchase Date: November 2024 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Chen, PE - Process Safety & Hygiene Consultant

"In audits across food, pharma, and chemical facilities, I consistently recommend ISO-certified viewports with polished stainless steel. This product line exceeds FDA and EU hygiene standards, and the Ra ≤ 0.8 µm surface finish significantly reduces biofilm risk. For regulated environments, the documentation and traceability are impeccable."

Thomas Reed - Senior Systems Engineer, Semiconductor Manufacturing

"For high-vacuum and UHV applications, visual access without compromising integrity is critical. The CF flange design here meets all necessary sealing specs, and the quartz-to-metal seal integrity has proven stable across repeated pump-down cycles. A reliable choice for precision industrial monitoring."

Posted: 2 days ago

"Replaced aging carbon steel viewports with the Advanced Model. Immediate improvement in both cleanability and corrosion resistance. Passed our last FDA audit with zero non-conformances related to sight glass components."

Posted: 1 week ago

"Ordered a set of 100mm flanged viewports with 10mm quartz. Delivery was fast, and every unit met spec. The real-time monitoring capability has reduced sampling frequency and improved process control."

Posted: 3 weeks ago

"Used the Base Model for a low-budget pilot reactor. Performs well under 30 bar. Appreciated the customization guidance from the sales team. Would love a mid-tier option with 316SS at a lower price point."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.