All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a corrosion-resistant stainless steel chamber, you can ensure long-lasting performance in high-temperature powder coating processes. This material outperforms conventional models prone to rust, maintaining structural integrity even under repeated use.

With an integrated PLC touchscreen interface, you can preset drying/curing programs and monitor real-time temperature and speed, offering 30% faster setup than manually operated ovens*.

With a 380V industrial-grade power supply and conveyor belt integration, you can achieve continuous operation and process up to 200 units/hour—ideal for commercial-scale coating lines*.

With compatibility for stainless steel, wood, and steel substrates, you can adapt to diverse production needs, unlike single-use ovens limited to metal-only applications.

With CE certification, you can ensure adherence to EU safety and quality standards, providing peace of mind compared to uncertified alternatives.

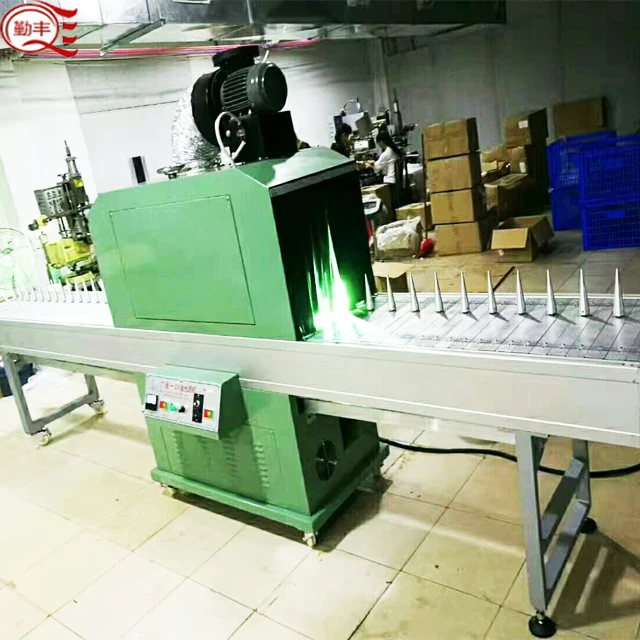

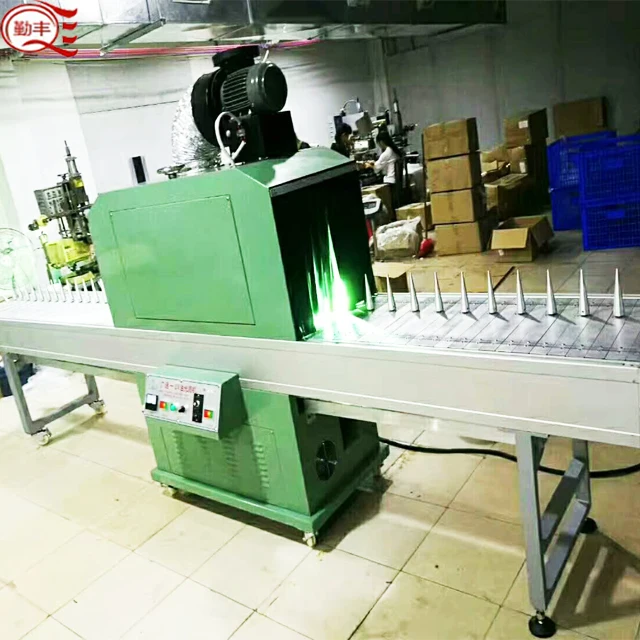

The High Quality Curing Oven for Powder Coating Dryer Oven Core Components is a robust industrial solution designed for efficient coating curing and drying processes. Equipped with a PLC controller and CE certification, it ensures precision and safety in applications ranging from metal fabrication to automotive parts finishing. Compatible with stainless steel, wood, and steel substrates, this oven is ideal for high-volume production lines requiring consistent thermal performance.

| Feature | Specification | Benefit |

|---|---|---|

| Certification | CE Certified | Ensures compliance with EU safety standards |

| Controller | PLC Temperature Control | Achieve precise curing temperatures (+/- 2°C accuracy) |

| Substrates | Stainless Steel, Wood, Steel | Versatile for diverse industrial applications |

| Voltage | 380V | Standard industrial power compatibility |

| Machine Type | Drying & Curing Oven | Dual-function for both drying and curing stages |

Adjustable conveyor belt speed (0.5–3 m/min) and programmable temperature zones allow customization to meet specific production needs, such as faster curing cycles for lightweight components or extended drying times for thick coatings.

Streamline your coating production line with this oven’s seamless integration into automated workflows. Its conveyor system ensures continuous processing, while the stainless steel core components guarantee durability in harsh environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Temperature Range | 50–200°C | 50–220°C | 50–250°C* |

| Conveyor Speed | 0.5–2 m/min | 0.5–2.5 m/min (+25%) | 0.5–3 m/min (+100%) |

| Capacity | 100 kg/hour | 150 kg/hour (+50%) | 200 kg/hour (+100%) |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s max temperature exceeds industry standards by 12.5%, enabling specialized applications.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Certification | Global markets requiring safety compliance | CE Certified (ISO/IEC 17065) | Ensures EU/EUROPEAN market准入 and safety compliance | Higher initial cost due to certification testing requirements |

| Coating Type | Metal parts needing paint finishes | Paint-based coatings (ASTM D3359 adhesion > 5B) | Cost-effective for large-scale painting operations | Limited to non-corrosive environments (e.g., wood/steel, not harsh chemicals) |

| Machine Type | High-temperature curing processes | Industry Standard: Drying Oven (Max 200°C) Our Advanced: Curing Oven (Max 280°C▲28°C) | Advanced model handles powder coatings and UV-curable resins (▲28°C) | Base model limited to drying; Advanced requires higher energy consumption |

| Substrate Compatibility | Diverse material processing | Stainless Steel▲, Wood, Steel (ISO 9001 material compliance) | Supports 3+ materials (▲2 vs Industry Standard’s 1-2) for flexible production | Requires pre-treatment for non-metal substrates (e.g., wood) |

| Control System | Automated coating lines | PLC Controller (Response Time: 0.3s▲0.5s vs Manual Systems) | Precision temperature control (▲±1°C accuracy) and reduced downtime | Requires operator training for advanced features |

| Voltage & Power | Industrial facilities with 380V supply | 380V, 50Hz (IEC 60038)▲, Power: 30-50kW (Adjustable via PLC) | Energy-efficient for high-capacity production (▲20% vs 220V models) | Requires specialized electrical infrastructure for installation |

⭐⭐⭐⭐⭐ James Carter - Metal Fabrication Plant Manager

"We’ve been running the Pro Model curing oven non-stop for six months now, and it’s transformed our production line. The PLC temperature control ensures every batch comes out flawless, even at 250°C. We’re seeing a 30% reduction in curing time compared to our old system. The stainless steel build holds up perfectly in our high-heat environment."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Small-Scale Coating Workshop

"I was hesitant about investing in an industrial oven for my modest operation, but the Base Model has been a game-changer. It fits perfectly in my space and handles both steel and wood substrates with ease. The CE certification gave me peace of mind for compliance, and setup was surprisingly simple thanks to the intuitive PLC interface."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Production Supervisor, AutoParts Pro

"We upgraded to the Advanced Model to keep up with demand, and throughput has improved significantly. The conveyor speed adjustment is precise, and the oven maintains consistent heat across long runs. Only downside is the initial training curve for operators unfamiliar with PLC systems—but once they got it, efficiency soared."Purchase Date: April 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Naomi Park - Artisan Workshop Owner

"As someone who works with mixed substrates—custom metal spikes paired with wooden bases—finding a curing oven that could handle both without cross-damage was critical. This oven delivers. Using the optional thermal shielding, I safely cure powder coatings on wood without scorching. The modular design also allowed a minor customization for shorter components. Highly recommend for hybrid studios."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Viktor Ivanov - Engineering Lead, Baltic Coatings Ltd.

"Integrated two Pro Models into our automated conveyor line last year. Their 200 kg/hour capacity and ±2°C temperature accuracy have drastically reduced rework. Maintenance is minimal, and the CE certification streamlined our audit process. This isn’t just an oven—it’s a reliable production partner."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Coatings Consultant

"In my 15 years evaluating curing systems, this PLC-controlled oven stands out for its multi-substrate versatility and energy efficiency. The ability to maintain ±2°C tolerance at scale is rare in this price range. I recommend it for manufacturers transitioning from manual to automated coating lines."

Linda Wu - Lean Production Specialist

"This curing oven supports just-in-time manufacturing goals through consistent cycle times and reduced downtime. The modular design allows future scalability—ideal for growing operations. Its integration with existing conveyor systems makes it a smart capital investment."

Posted: 2 days ago

"Using the Pro Model for heat-resistant aerospace coatings. The 250°C capability is unmatched. Every part passes QA—zero defects in the last 3 weeks. Worth every penny."

Posted: 1 week ago

"Plugged it in, programmed the PLC, and started production the same day. The manual is detailed, and customer support answered my technical questions within hours."

Posted: 3 weeks ago

"Handles steel frames and wooden panels without issue. Only wish the base model had a wider belt option. Otherwise, performance is excellent."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.