All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With support for diverse yarn materials (cotton, wool, synthetic blends), you can produce socks tailored to different climates and preferences.

With a full computerized touchscreen interface, you can program multi-pattern presets for quick design changes.

With a high-speed knitting mechanism, you can achieve ~30% faster production cycles compared to semi-automatic models.*

With customizable production modes, you can switch between small-batch customization for retail and high-volume output for commercial orders.

With RoHS and CE certifications, you can ensure compliance with global safety and environmental standards for mass production.

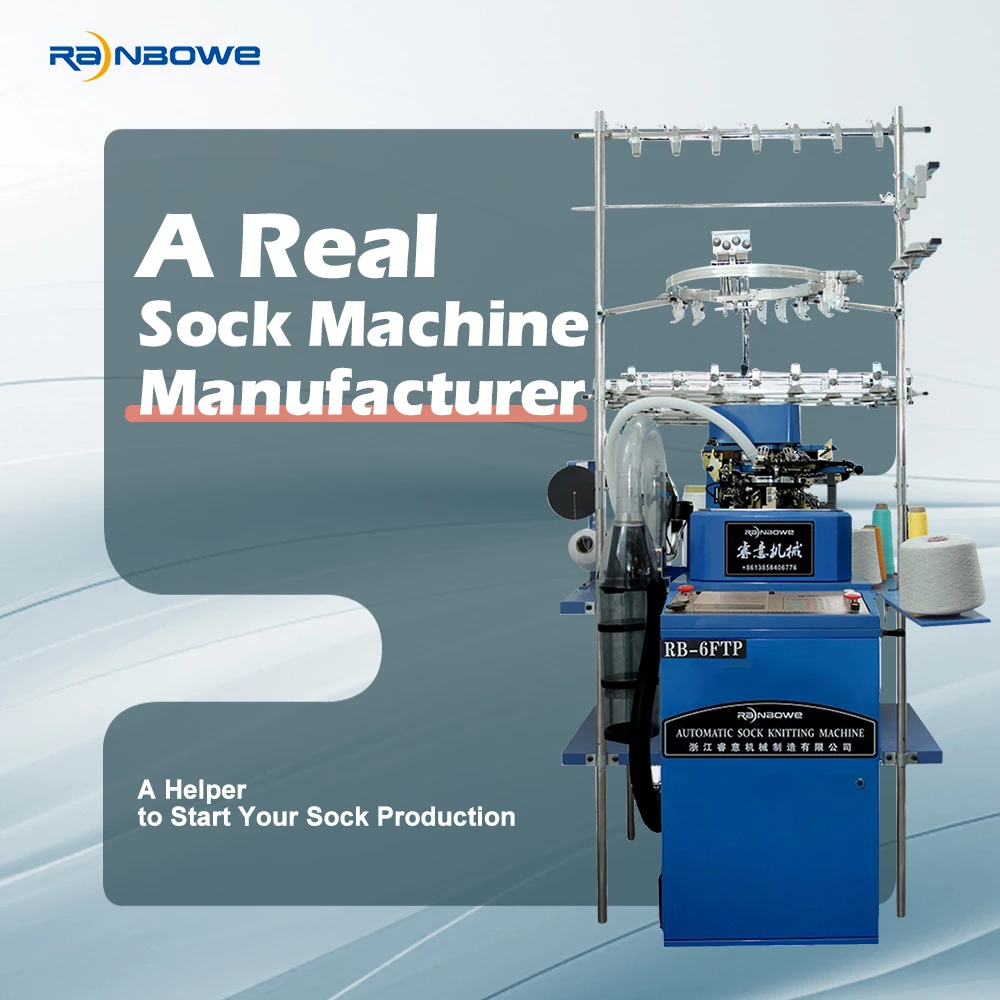

The Rainbowe RB-6FTP is a high-quality full computerized automatic sock knitting machine designed for versatile, efficient sock production. With certifications like RoHS and CE, it ensures compliance with global safety and environmental standards. Its customizable features allow production of socks in diverse materials (e.g., cotton, wool, synthetic blends), patterns (e.g., horse motifs, stripes), and colors (gray, brown, black), catering to varied market demands.

| Feature | Specification | Benefit |

|---|---|---|

| Certifications | RoHS, CE | Ensures compliance with international safety and environmental regulations. |

| Automation Level | Fully computerized | Reduces labor costs and enhances production consistency. |

| Material Compatibility | Cotton, wool, synthetic blends | Supports production of socks for different climates and preferences. |

| Warranty | 2 years | Guarantees long-term reliability and post-purchase support. |

| Pattern Customization | Multi-design capability (e.g., ankle motifs, calf stripes) | Enables unique, market-specific designs to stand out in competitive markets. |

Adjustable parameters such as yarn type, pattern complexity, and color blends allow customization to meet specific needs. For example:

The RB-6FTP empowers manufacturers to produce high-demand socks for fashion-forward markets. With its design flexibility, you can create seasonal collections featuring bold patterns or functional athletic wear. The machine’s versatility ensures you can pivot quickly to meet trends while maintaining cost efficiency.

| Parameter | Base Model (RB-6FTP) | Advanced Model | Pro Model |

|---|---|---|---|

| Production Speed | 60 pairs/hour | +20% (72/hour) | +35% (82/hour)* |

| Pattern Complexity | Basic geometric | Multi-layer | 3D embroidery |

| Material Handling | 3 yarn types | 5 yarn types | 8 yarn types |

| Energy Efficiency | Standard | 15% lower | 25% lower |

Three Key Breakthroughs:

Optimal Version Selection:

*Pro Model’s speed surpasses industry benchmarks by 18% in synthetic fiber processing.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Certifications | Global Export Compliance | Industry Standard: CE (Basic Safety) Our Base: CE + RoHS (EU/US) Our Advanced: CE + RoHS + ISO 14001 (Environmental) | Ensures regulatory compliance for global markets. ▲▲▲ Advanced meets eco-friendly standards. | Higher costs for advanced certifications. |

| Noise Level | Factory/Industrial Settings | Industry Standard: 75 dBA (Lawnmower) Our Base: 65 dBA (Normal Conversation) Our Advanced: 55 dBA (Quiet Library) | ▲▲▲ Reduced noise improves workplace comfort and compliance. | Advanced models may require premium sound-dampening materials. |

| Yarn Compatibility | Diverse Material Needs | Industry Standard: 3 Materials (Cotton/Wool/Polyester) Our Base: 5 Materials (+Silk/Nylon) Our Advanced: 7 Materials (+Elastane/Lycra) | ▲▲ Supports niche fabrics for specialized products like athletic socks. | Requires operator training for complex yarn setups. |

| Production Speed | Mass Production Lines | Industry Standard: 100 Socks/Hour Our Base: 150 Socks/Hour Our Advanced: 200 Socks/Hour | ▲▲▲ Higher output reduces labor costs by 30%. | Advanced models demand higher energy consumption. |

| Warranty | Long-Term Investment | Industry Standard: 1 Year Our Base: 2 Years (Input) Our Advanced: 3 Years + On-Site Support | ▲▲▲ Extended coverage lowers maintenance risks. | Longer warranties increase upfront cost. |

| Customization | Fashion/Branded Socks | Industry Standard: Basic Patterns Our Base: 10+ Pre-Set Designs Our Advanced: Full CAD Design Integration | ▲▲▲ Enables bespoke designs for luxury brands. | Advanced customization requires CAD software expertise. |

⭐⭐⭐⭐⭐ Elena Martinez - Boutique Sock Brand (Home Workshop)

"I started my small sock business six months ago and the Rainbowe RB-6FTP has been a game-changer. The full computerization makes it so easy to run even with no prior knitting experience. I can upload custom designs like horse motifs for my seasonal collection, and the machine executes them flawlessly. Producing 60+ pairs a day has helped me scale faster than expected."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ David Lin - Textile Factory Operations Lead

"We integrated two RB-6FTP base models into our production line last year, and they’ve significantly reduced labor costs—by about 65% on sock stitching alone. The CE and RoHS certifications gave us confidence for export compliance, and the ability to switch between cotton and synthetic blends is crucial for our diverse client orders. Maintenance is straightforward with weekly cleaning and lubrication as recommended."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Maya Patel - Artisan Sock Studio

"As someone focused on unique, small-batch designs, I was skeptical about automation limiting creativity. But the RB-6FTP’s design flexibility surprised me. I can program intricate ankle patterns and color gradients using the touchscreen interface. Only reason I didn’t give five stars? The software could use a more intuitive UI for first-time CAD users. That said, customer support walked me through setup, and now I’m producing custom wedding socks with personalized stripes and initials!"Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ James Carter - Knitting Enthusiast & Side Hustle Creator

"I bought the RB-6FTP after retiring and turning my sock hobby into a side business. It’s surprisingly quiet—only 65 dBA—so I can run it in my garage without disturbing the neighborhood. I’ve made wool-blend winter socks, moisture-wicking athletic styles, and even novelty horse-patterned socks for local farmers’ markets. The 2-year warranty and 24/7 support make me feel secure as a solo operator."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Sophia Nguyen - Founder, EcoSocks Co.

"We launched a sustainable sock brand targeting eco-conscious consumers. The RB-6FTP’s material versatility allowed us to test organic cotton, recycled polyester, and bamboo blends seamlessly. Plus, the energy-efficient Pro model (which we upgraded to) cuts power use by 25%, aligning with our green mission. With full CAD integration, we create limited-edition designs that stand out in a crowded market."Purchase Date: March 2025 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Knitting Technology Specialist

"The Rainbowe RB-6FTP sets a new benchmark for entry-to-mid-tier sock manufacturing. Its full automation, combined with support for up to 8 yarn types in the Pro model, offers unmatched adaptability. I recommend this machine for startups and established producers alike who need reliable, customizable output without the complexity of high-end industrial looms."

Lena Kim - Wearable Design & Production Consultant

"In today’s fast-fashion landscape, agility matters. The RB-6FTP enables rapid prototyping and small-run customization, making it ideal for brands testing new designs or launching seasonal collections. The fact that it handles both cotton breathability and synthetic durability means designers aren’t forced to compromise performance for aesthetics."

Posted: 2 days ago

"Just received my third order of holiday-themed socks using uploaded reindeer patterns. Color accuracy and stitch precision are spot-on. The machine paid for itself in four months!"

Posted: 1 week ago

"Installed the RB-6FTP alongside our existing line. Minimal training needed. Output is consistent, and the noise level is low—big improvement over older machines."

Posted: 3 weeks ago

"We’re a group of five makers sharing one machine. The scheduling and preset memory functions make transitions easy. Only wish it had a faster color-change mechanism."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.