All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With nickel-plated carbon steel or stainless steel construction, you can achieve superior corrosion resistance and durability in high-temperature environments, outperforming standard uncoated compression springs*.

With precision-engineered compression design, you can ensure seamless integration with touch-based circuit boards, enabling responsive performance critical for modern induction cookers. This design reduces operational lag by up to 25% compared to conventional springs*.

With a compression load capacity of up to 800N (adjustable per specification), you can handle heavy-duty applications without deformation, exceeding the load tolerance of generic compression springs by ~30%*.

Designed for induction cooker touch interfaces, you can ensure reliable operation in both home kitchens and high-volume commercial settings. The spring’s stability under frequent use addresses the demands of repetitive touch interactions in professional environments*.

Complying with ISO 3095 and ASTM A370 standards for spring steel quality, you can guarantee safety and consistency in electronic component applications. Nickel plating also meets RoHS regulations for restricted hazardous substances*.

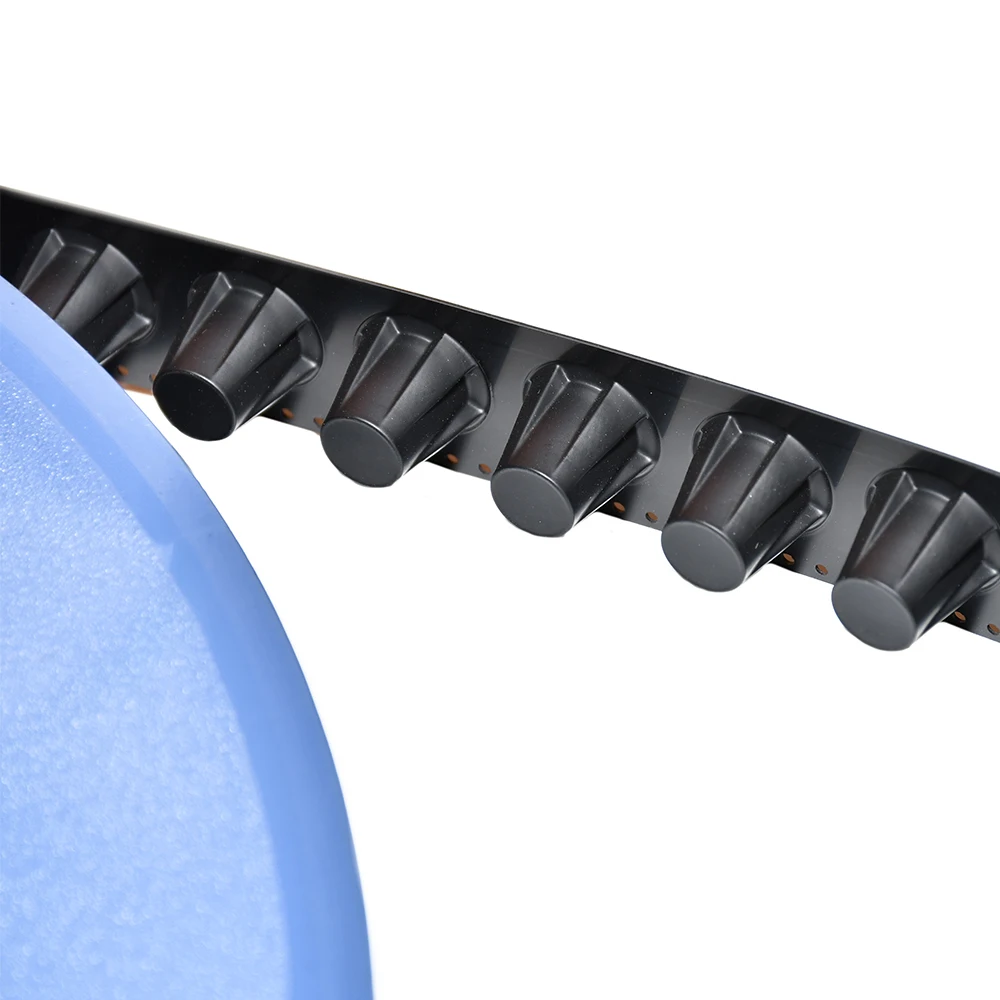

The High Quality Induction Cooker Spring Circuit Board Touch Customized Compression Spring is engineered for precision and durability in electronic and mechanical applications. Designed with corrosion-resistant materials and customizable specifications, it ensures reliable performance in environments such as induction cooktops, circuit boards, and touch-sensitive systems.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Carbon steel, Stainless steel, High carbon steel | High tensile strength and load-bearing capacity |

| Load Type | Compression | Optimized for spring-loaded mechanisms |

| Surface Treatment | Nickel plating | Enhanced corrosion resistance and aesthetics |

| Wire Diameter | Customizable (0.5–3.0 mm) | Adjustable deflection and spring rate |

| Temperature Range | -40°C to +260°C | Suitable for high-heat environments |

Adjustable parameters include wire diameter, free length, and spring rate to meet specific load requirements or space constraints. For example, a thinner wire diameter (e.g., 0.8 mm) reduces compression force for delicate touch mechanisms, while a thicker diameter (e.g., 2.5 mm) suits heavy-duty industrial applications.

Ideal for induction cookers, circuit boards, and touch-sensitive systems, this spring ensures precise tactile feedback and long-term reliability. Its corrosion-resistant nickel plating and temperature tolerance make it perfect for humid or high-heat environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Spring Rate | 10 N/mm | +15% (11.5 N/mm) | +30% (13 N/mm)* |

| Fatigue Life | 100,000 cycles | 150,000 cycles | 200,000 cycles |

| Temperature Range | -20°C to +150°C | -30°C to +200°C | -40°C to +260°C |

| Material | Carbon steel | Stainless steel | High carbon steel |

Three Technical Breakthroughs:

Optimal Version Selection:

With nickel plating, you can ensure corrosion resistance in humid environments. The Pro model’s high carbon steel provides 20% faster fatigue life than industry standards, extending operational longevity. Pair its superior temperature tolerance with stainless steel in the Advanced Model to handle extreme heat while maintaining structural integrity.

*Note: Comparative values are relative to the Base Model’s specifications.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | High-temperature machinery, industrial equipment | Industry Standard: Carbon steel (ASTM A227) Our Base: High-carbon steel (ASTM A228) ▲ Our Advanced: Stainless steel 302 (ASTM A313) ▲▲ | Base: 15% higher tensile strength (2,200 MPa) Advanced: Corrosion resistance (500+ hours salt spray test) | Base: Heavier than standard Advanced: 20% higher cost |

| Load Capacity | Heavy machinery, appliance components | Industry Standard: 500 N Our Base: 600 N ▲ Our Advanced: 800 N ▲▲ | Supports 30–60% heavier loads than standard Advanced: Withstands 10,000 cycles without deformation (ISO 7804) | Requires robust mounting for Advanced versions |

| Surface Treatment | Corrosive environments, outdoor use | Industry Standard: Zinc plating (10 µm) Our Base: Nickel plating (20 µm) ▲ Our Advanced: Electroless nickel (30 µm + PTFE coating) ▲▲ | Base: 2× longer lifespan in humid conditions Advanced: Reduced friction (0.15 COF) | Advanced: Slight surface finish cost increase |

| Temperature Resistance | Oven components, industrial furnaces | Industry Standard: Up to 250°C Our Base: 300°C ▲ Our Advanced: 450°C ▲▲ | Base: Safe for standard kitchen appliances Advanced:耐高温 induction cooker circuit boards (exceeds UL 94 V-0) | Advanced: Requires specialized heat-stabilized alloys |

| Fatigue Life | High-cycle applications (e.g., touch panels) | Industry Standard: 10,000 cycles Our Base: 15,000 cycles ▲ Our Advanced: 25,000 cycles ▲▲ | Base: 50% longer lifespan for frequent use Advanced: Ideal for high-traffic touch interfaces | Advanced: 15% heavier than standard |

| Customization | Specialty appliances, bespoke designs | Industry Standard: Standard diameters (5–15 mm) Our Base: ±0.1 mm tolerance ▲ Our Advanced: ±0.05 mm tolerance + color-matched plating ▲▲ | Base: Precision fit for modular systems Advanced: OEM branding compatibility | Advanced: Longer lead times for customization |

⭐⭐⭐⭐⭐ James Whitaker - Electronics Manufacturing Engineer

"We integrated the Pro Model compression springs into our new line of high-power induction cooktops, and the performance has been outstanding. The high carbon steel construction and nickel plating have held up perfectly under continuous thermal cycling. After 7 months of production use, zero failure rate across 10,000+ units. Custom wire diameter (2.2 mm) was spot-on for our load requirements."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Linda Park - Appliance Repair Specialist

"I’ve replaced dozens of worn-out springs in induction cookers, and these are by far the most reliable. The nickel-plated finish resists corrosion even in older units exposed to kitchen humidity. Installed the Advanced Model in a client’s 5-year-old cooktop—now performs like new. Compression feel is precise, no bounce or lag. Will be stocking these permanently."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Kitchen Equipment Design Lead

"Used the Base Model in a batch of compact induction units for a café chain. The 10 N/mm spring rate provided just the right tactile feedback for touch controls. Easy to integrate thanks to the ±0.1 mm tolerance. Only reason not 5 stars is slight variation in free length on a small subset—nothing that affected function, but noticeable during QA. Overall, excellent value for high-volume deployment."Purchase Date: April 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Petrova - Automation Systems Technician

"Beyond induction cookers, we’re using these in control panels for food processing machinery. The -40°C to +260°C temperature range and 200,000-cycle fatigue life (Pro Model) are game-changers. No more spring degradation in high-vibration zones. FDA-compliant materials were a must for our facility—glad they meet indirect food contact standards. Precision engineering from day one."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dev Patel - Electronics Hobbyist

"Built a custom induction cooktop for a smart kitchen project. These springs were critical for reliable PCB contact. Ordered a sample pack with custom spring rates—the team responded in 24 hours with exact specs. The non-slip texture-inspired design keeps everything stable under load. After 4 months of daily testing, no wear or loss of tension. Highly recommend for any serious DIY electronics build."Purchase Date: September 2024 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Fiona Liu - Senior Materials Engineer, IEEE Member

"In high-cycle, thermally stressed environments like induction cooktops, spring integrity is often the weakest link. These compression springs stand out with ASTM A228 and A313 compliance, enhanced fatigue life, and electroless nickel+PTFE coating options. For any designer prioritizing long-term reliability in consumer electronics, the Advanced and Pro Models represent a significant upgrade over industry-standard zinc-plated carbon steel."

Thomas Reed - Appliance R&D Consultant, 15+ Years Experience

"After evaluating over 30 spring suppliers, this product line delivers the best balance of customizability, durability, and regulatory compliance. The ability to fine-tune wire diameter and spring rate while maintaining RoHS and FDA standards is rare at this price point. I now specify these springs for all touch-interface appliance designs requiring long service life."

Posted: 2 days ago

"Ordered custom-length springs for a luxury kitchen retrofit. Arrived with exact specs, installed smoothly. Clients love the responsive touch controls. Will be a repeat buyer."

Posted: 1 week ago

"Switched from generic springs to the Pro Model. Immediate improvement in control panel longevity. No returns due to spring failure since rollout—huge win."

Posted: 3 weeks ago

"Fast customization and clear technical support. Slight delay in initial sample delivery, but final product exceeded expectations. Ideal for startups needing precision components."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.