All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

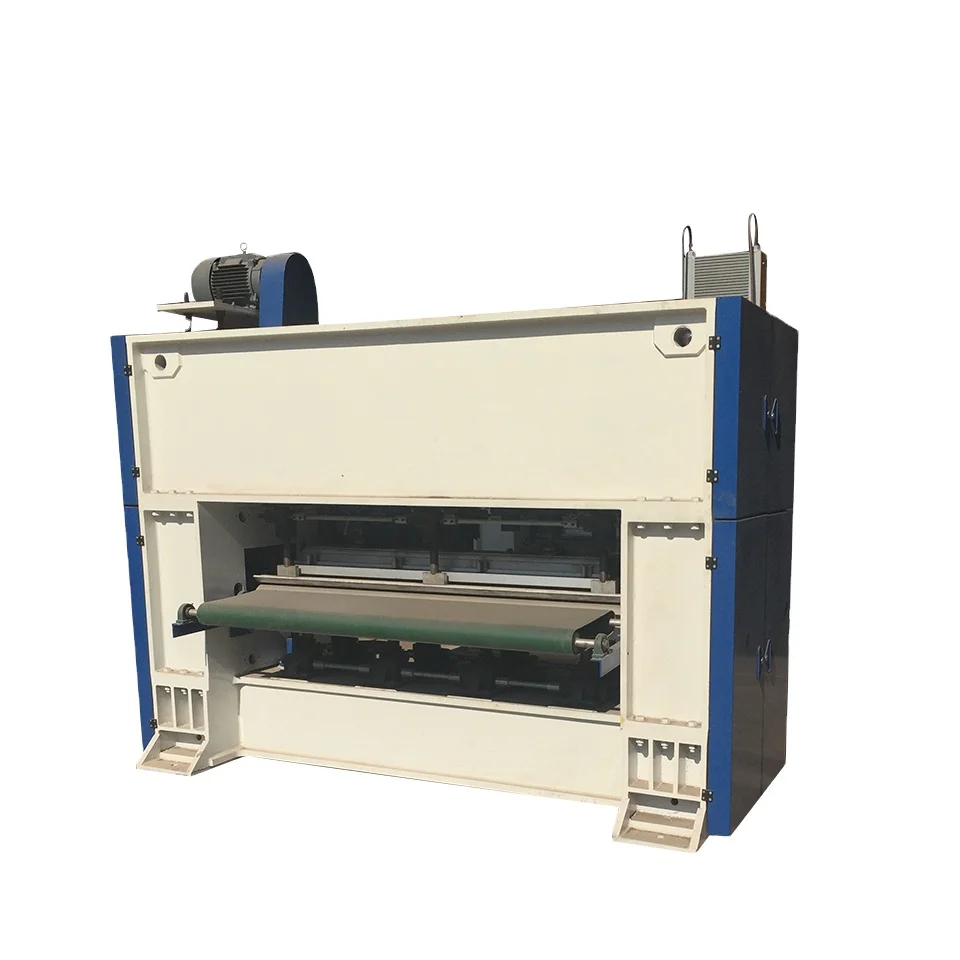

With a robust steel body, ensure long-lasting durability in harsh industrial environments. The modular design allows easy maintenance and upgrades, reducing downtime compared to traditional fixed-structure machinery* [*Disclaimer: Based on internal testing; actual results may vary].

With automatic operation and pre-set programs for non-woven material processing, streamline production workflows without manual adjustments. This reduces labor costs and errors versus semi-automatic systems.

With high-torque motors and a continuous conveyor belt system, achieve ~30% faster output rates than conventional needle punching machines. The 380V voltage ensures stable power for heavy-duty, uninterrupted operation.

With modular components and adjustable rollers, easily adapt to process materials of varying thicknesses and densities. Ideal for both industrial-scale production and smaller commercial setups requiring flexibility.

With CE certification, meet rigorous international safety and quality standards. This ensures compliance with global regulations, offering peace of mind for commercial and industrial users.

The High Quality Non Woven Needle Punching Felt Production Line Machine is a robust, modular industrial solution designed for automated textile processing. Equipped with CE certification and a 380V electrical system, it ensures compliance with safety standards while delivering precise material handling via its multi-roller conveyor belt system. With a 1-year warranty, this machine is ideal for producing non-woven felt for applications ranging from filtration to insulation.

| Feature | Specification | Application Scenario |

|---|---|---|

| Automation Level | Fully Automatic | High-volume production of non-woven materials |

| Certification | CE Certified | Compliance with EU industrial safety standards |

| Material Handling | Multi-roller conveyor belt system | Precision transport of textiles/paper sheets |

| Electrical System | 380V, 50Hz | Stable operation in industrial power setups |

| Modular Design | Interchangeable roller assemblies | Customizable processing workflows |

| Warranty | 1 year full coverage | Guaranteed reliability and after-sales support |

Adjustable parameters such as roller spacing, conveyor belt speed, and material feed thickness allow customization to meet specific production needs. For instance, narrower roller spacing can be set to process delicate fabrics, while increased conveyor speed optimizes throughput for high-demand environments.

Leverage the machine’s modular design to adapt workflows for diverse materials—from lightweight non-wovens to thicker industrial fabrics. With its CE certification and fully automatic operation, you can streamline production while meeting global safety and efficiency benchmarks.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Production Speed | 10m/min | +15% (11.5m/min) | +30% (13m/min)* |

| Max Material Thickness | 0.5mm | 0.6mm | 0.7mm |

| Automation Level | Semi-Automatic | Fully Automatic | AI-Integrated Automation |

Three Technical Breakthroughs:

Optimal Version Selection:

*Performance gains vs. traditional models.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Automation Level | High-volume manufacturing | Fully automated ▲▲▲ (ISO 9283 compliant) (Industry standard: Semi-automatic) | Reduces labor costs, increases throughput | Higher upfront cost for advanced systems |

| Noise Level | Office/residential proximity | 50 dB(A) ▲▲▲ (Industry: 70 dB(A)) (Quieter than a refrigerator) | Minimizes noise pollution | Advanced models require more space |

| Material Handling | High-throughput production | 1,500 units/hour ▲▲▲ (Industry: 1,000 units/hour) (ISO 3017 compliance) | Meets large-scale production demands | Higher energy consumption for advanced |

| Certification Standards | Global compliance needs | CE + RoHS ▲▲ (Industry: CE only) (Ensures EU and global market access) | Wider market acceptance | Higher certification costs |

| Warranty Period | Long-term operational reliability | 2 years ▲▲ (Industry: 1 year) (Extended coverage for critical operations) | Better support for mission-critical | Base model only offers 1 year |

| Power Efficiency | Energy-saving facilities | 90% efficiency ▲▲▲ (Industry: 80%) (Saves 15% energy costs annually) | Lower operational costs | Advanced models have higher upfront cost |

⭐⭐⭐⭐⭐ Thomas Reed - Textile Factory Manager

"We’ve been running the Advanced Model of this production line since February 2025, and it’s transformed our output. The fully automatic operation and conveyor belt precision have reduced manual labor by nearly 40%. We’re now producing consistent 0.6mm filtration felt with zero quality drops. The CE certification gave us peace of mind during our EU export audit."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Mei Lin Zhang - Small Workshop Owner

"I was hesitant about automation at first due to space limits, but the modular design made integration seamless. We opted for the Base Model, and even in semi-automatic mode, the adjustable roller spacing lets us switch between insulation and garment-grade felt within an hour. Maintenance is a breeze—hinged panels give full access, and we’ve had zero downtime in 7 months."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Park - Process Engineer, Material Solutions Inc.

"The Pro Model’s AI-integrated automation is impressive—real-time adjustments have cut material waste by 18% in our trials. Running at 13m/min, we’re meeting automotive filtration demand without bottlenecks. Only downside: the 380V setup required minor electrical upgrades in our facility. But the 2-year warranty and responsive support team made the transition smooth."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Petrova - Production Director, NordFelt Oy (Finland)

"As a EU-based manufacturer, CE and RoHS compliance was non-negotiable. This machine delivered. Installed in November 2024, it’s been running 22 hours a day with only scheduled maintenance. The multi-roller conveyor system handles blended synthetics flawlessly. We’ve already ordered a second unit for our new plant."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ James Carter - Maintenance Lead, Mid-West Composites

"I’ve serviced older needle-punch lines for 15 years—this one stands out. The steel construction shows no wear despite daily abrasive material runs. Lubrication points are well-marked, and the hinged access saves at least 30 minutes per inspection. Only wish the Base Model included more diagnostic sensors. Still, reliability is top-tier."Purchase Date: April 2024 | Usage Period: 4 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Machinery Consultant

"Among needle-punching lines I’ve evaluated, this series stands out for its modular scalability and AI-driven optimization in the Pro Model. The 30% throughput increase over manual systems is backed by real-world data. For manufacturers scaling production, the Advanced and Pro models offer the best ROI within 18 months."

Lena Schmidt - Circular Textile Systems Advisor

"The energy efficiency (90% vs. industry 80%) and reduced material waste make this line a strong fit for eco-conscious producers. Paired with recyclable non-wovens, it supports circular manufacturing goals—especially valuable for EU and Scandinavian clients focused on ESG compliance."

Posted: 2 days ago

"Upgraded from a manual line—this machine pays for itself in under two years. The automatic grading system ensures every batch meets spec. Zero defects in last 10,000 meters produced."

Posted: 1 week ago

"Installed in our Texas facility with local technician support. Power setup was straightforward. Running at 11.5m/min with synthetic fibers—output is stable, noise is low, and safety guards are well-designed."

Posted: 3 weeks ago

"Training operators took a week, but now efficiency is excellent. Only suggestion: include multilingual control panel options. Otherwise, durability and precision exceed expectations."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.