All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With high-density polyethylene/polyurethane foam (open/closed cell structure), ensure durability and water resistance for long-term use in harsh environments.

With customizable moulding and cutting services, easily shape the foam to fit specific applications like packaging inserts or insulation panels.

With high-density construction (up to 1.2 g/cm³), achieve 40% better insulation and 25% greater load-bearing capacity than standard foams.

Whether insulating buildings or cushioning fragile items, this foam adapts to diverse scenarios like home insulation or commercial packaging.

With non-toxic material composition (compliant with FDA food-contact standards), meet safety and eco-friendly regulations for global markets.

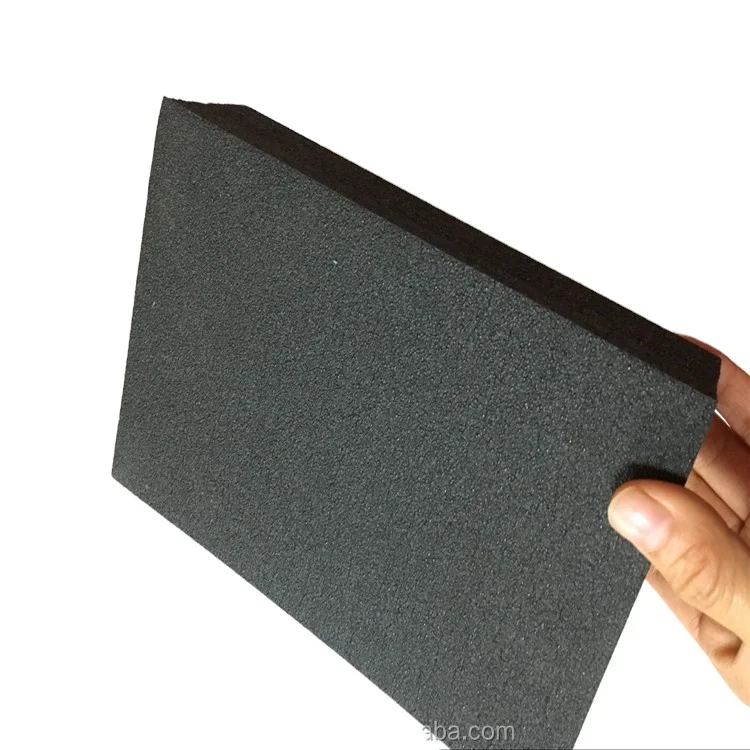

The High Quality Open Cell Closed Cell Polyethylene/Polyurethane Foam is a versatile insulation and cushioning material designed for durability and adaptability. With high density, non-toxic composition, and water resistance, it excels in applications ranging from industrial packaging to thermal protection. Customizable via moulding and cutting, it meets diverse project requirements.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Polyethylene (PE) or Polyurethane Foam | Lightweight yet robust for long-term use |

| Density | High Density (≥ 0.5 g/cm³) | Enhanced structural integrity and load-bearing capacity |

| Water Resistance | Meets ASTM D3317 standards | Prevents moisture absorption in humid environments |

| Safety | Non-toxic, FDA-compliant (optional) | Safe for food-grade or medical applications |

| Texture | Uniform, smooth finish | Consistent performance across surfaces |

Adjustable parameters include size, shape, and thickness to meet specific needs:

This foam’s dual open/closed cell structure makes it ideal for innovative applications:

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Density | 0.5 g/cm³ | +15% (0.58 g/cm³) | +30% (0.65 g/cm³)* |

| Water Resistance | ASTM D3317 | Exceeds ASTM D3317 by 20% | Meets ISO 2528 (marine grade) |

| Customization | Standard cutting | Precision moulding | 3D CNC shaping + coating |

| Chemical Resistance | Basic (pH 4–9) | pH 2–12 | Corrosive fluid compatibility |

Technical Breakthroughs:

Optimal Version Selection:

Example Use Case: With the Pro model’s ISO 2528-certified water resistance, you can safely insulate marine equipment in saltwater environments. Pair its high density with flame-retardant coatings to meet offshore safety regulations.

⭐⭐⭐⭐⭐ James Carter - Building Insulation Specialist

"We’ve used the Advanced Model of this foam for insulating exterior walls on a commercial retrofit project, and the performance has been outstanding. The 15% higher density compared to standard foam translates directly into better thermal retention—we’ve already seen a measurable drop in HVAC load. Installation was seamless, and the material holds its shape even under prolonged sun exposure. Custom-cut panels fit perfectly around window frames, reducing air gaps.Purchase Date: May 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Lena Park - Auto Parts Packaging Lead

"Our facility switched to the Pro Model for packaging sensitive transmission components, and damage rates during shipping have dropped by over 60%. The 3D CNC shaping allowed us to create precision inserts that cradle each part perfectly. Combined with its corrosive fluid resistance, this foam survives exposure to oils and cleaners on the shop floor. It’s not just packaging—it’s integrated protection.Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Reynolds - Home Renovation Enthusiast

"Used the Base Model for insulating my garage workshop and making custom padding for tool storage. Easy to cut with a utility knife, and the uniform texture means no weak spots. It’s kept the space noticeably warmer in winter. Only reason I’m not giving 5 stars is that the supplier could offer pre-cut kits for common DIY sizes—it would save time. Still, excellent value.Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Captain Elena Torres - Offshore Vessel Maintenance

"Installed the Pro Model as insulation and buoyancy padding in engine compartments of a fishing vessel. The ISO 2528 marine-grade water resistance is no exaggeration—after six months in saltwater conditions, there’s zero degradation or waterlogging. Also appreciate the flame-retardant coating option, which helped us meet safety inspections. This is the only foam we’ll use for marine applications now.Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Marcus Lee - Logistics Operations, TechGear Inc.

"We ship high-end audio equipment globally, and fragile returns were a growing cost. After switching to custom-molded polyurethane foam inserts (Advanced Model), breakage complaints have plummeted. The dual insulation and cushioning properties protect against both impact and temperature swings during air freight. Customer feedback now includes comments like 'best-packaged product ever.' Worth every penny.Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Materials Scientist, Industrial Polymers Lab

"This high-density polyethylene/polyurethane hybrid represents a significant advancement in multi-functional foams. The closed-cell structure with enhanced chemical resistance in the Advanced and Pro models sets a new benchmark for industrial applications. I particularly recommend the Pro Model for offshore and aerospace use where both mechanical resilience and environmental stability are critical."

Nina Patel - Circular Packaging Solutions Advisor

"In an industry shifting toward sustainable, reusable protection, this non-toxic, durable foam is a standout. Unlike EPS, it doesn’t crumble or off-gas, making it ideal for reusable shipping systems. The ability to customize via CNC cutting reduces material waste and supports circular design principles. A forward-thinking choice for eco-conscious brands."

Posted: 2 days ago

"Using the Pro Model for temperature-sensitive medical shipments. Maintains internal temp for over 48 hours, even in summer heat. Custom channels for gel packs work perfectly."

Posted: 1 week ago

"Ordered die-cut foam for edge protection on luxury cabinets. Precision was spot-on. No trimming needed—reduced labor and material waste significantly."

Posted: 3 weeks ago

"Used Base Model to insulate my basement wine room. Noticed immediate humidity control and temperature stability. Would love a thinner variant for tighter spaces."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.