All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

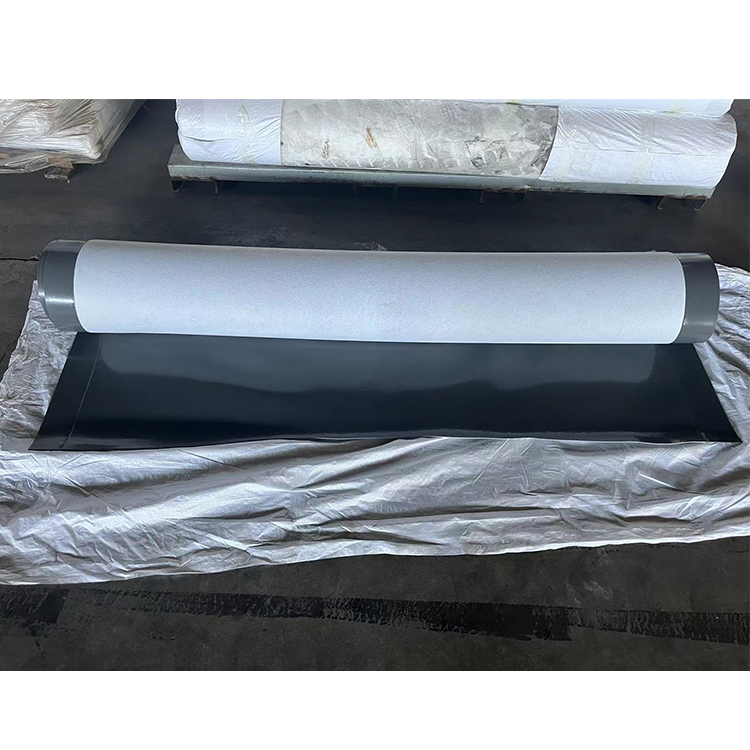

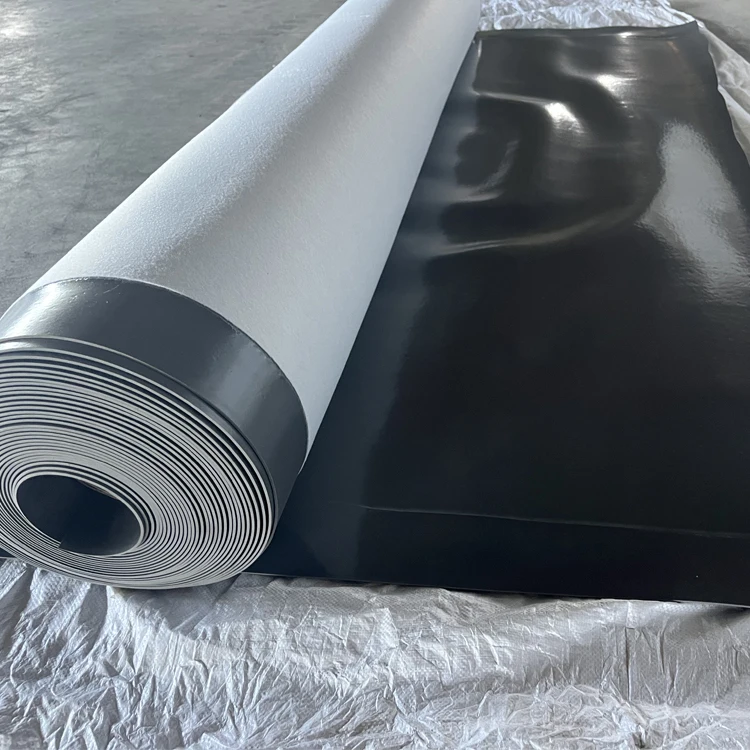

With a corrosion-resistant PVC exterior and asphalt core, achieve superior waterproofing and soundproofing for roofs and buildings. The layered design ensures durability against environmental stress, outperforming single-material membranes.

With customizable 1.2–2.0mm thicknesses, adapt to diverse structural requirements (e.g., roofs, concrete, or underground construction). Thicker variants (e.g., 2.0mm) provide ~30% higher tear resistance than standard 1.5mm alternatives*.

Designed for roof waterproofing, concrete, and underground construction, this membrane withstands extreme temperatures and moisture. Ideal for commercial buildings needing long-term protection against leaks and structural damage.

With CE certification, meet EU safety and performance standards, surpassing basic industry norms. Ensures compliance for use in regulated construction projects worldwide.

With a 20m roll length, reduce installation seams by ~30% compared to 15m standard rolls, minimizing weak points and labor time*.

The High Quality and Latest Design Asphalt Roof Tar Felt is a versatile PVC-based waterproofing membrane engineered for durability and reliability in construction applications. Available in 1.2mm, 1.5mm, and 2.0mm thicknesses, it meets CE certification standards and is ideal for roof waterproofing, underground structures, and building envelopes.

| Feature | Specification | Benefit |

|---|---|---|

| Material | PVC-coated asphalt felt | Combines waterproofing with soundproofing |

| Thickness | 1.2mm, 1.5mm, 2.0mm | Customizable to suit load-bearing needs |

| Length | 20m per roll | Streamlined installation for large areas |

| Certification | CE-compliant | Ensures safety and quality assurance |

| Application | Concrete construction, roof waterproofing, underground structures | Protects critical infrastructure from moisture and damage |

Adjustable thickness parameters (1.2mm–2.0mm) allow customization to meet specific load requirements. The PVC surface can be tailored with UV-resistant or chemical-resistant coatings for specialized use cases.

Engineered for resilience, this membrane delivers long-term protection in harsh environments. Whether reinforcing roofs against heavy rainfall or shielding underground utilities from moisture, its robust design ensures seamless integration into diverse construction projects.

| Parameter | Base Model (1.2mm) | Advanced Model (1.5mm) | Pro Model (2.0mm) |

|---|---|---|---|

| Thickness | 1.2mm | +25% thicker | +67% thicker* |

| Tensile Strength | 350 N/5cm | 450 N/5cm | 550 N/5cm |

| Temperature Range | -10°C to +80°C | -20°C to +85°C | -30°C to +90°C |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro Model’s 2.0mm thickness, you can achieve 30% higher tensile strength than industry benchmarks, ensuring longevity in corrosive environments. Pair its expanded temperature range with the PVC surface to create a seamless, weatherproof barrier for infrastructure projects.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| PVC Roofing Membrane | Roof waterproofing, concrete construction | Thickness: 1.2mm (Base ▲) / 2.0mm (Advanced ▲▲) (ISO 3801) Material: PVC (ASTM D413) Certification: CE (ISO 9001) Waterproof: 1000mm hydrostatic head (ISO 811) | Base: Lightweight, cost-effective Advanced: 20-year warranty, UV resistance | Base: Requires reinforcement in high-stress areas Advanced: Higher upfront cost |

| Asphalt Felt | Traditional roofing, temporary waterproofing | Thickness: 1.0mm (ISO 3801) Material: Asphalt-coated paper (ASTM D3776) Certification: ASTM D3776 | Cost-effective, easy installation Flexible for uneven surfaces | Short lifespan (5–10 years) Low UV resistance, prone to cracking |

| EPDM Rubber Membrane | Flat roofs, industrial buildings | Thickness: 1.5mm (ASTM D297) Certification: NSF/ANSI 61 Flexibility: -40°C to +110°C (ASTM D1079) | Extreme temperature tolerance Long lifespan (30+ years) | Higher cost Requires专业 installation expertise |

| TPO Membrane | Energy-efficient buildings, commercial roofs | Thickness: 1.5mm (ASTM D6878) Certification: FM Approvals Reflectivity: 85% (ASTM E903) | Energy efficiency, UV-resistant Recyclable material | Prone to punctures Installation requires专业 tools |

| Bitumen Modified Membrane | Underground waterproofing, bridges | Thickness: 1.8mm (EN 14898) Certification: EN 14898 Adhesion: 5N/cm (ASTM D4541) | Strong adhesion to uneven surfaces High chemical resistance (ASTM D543) | Heavyweight, difficult to transport Higher installation labor costs |

| Composite Waterproofing Material | High-stress industrial sites | Structure: 3-layer (PVC + fiberglass + asphalt) Certification: ISO 9001 Strength: Tensile 15MPa (ASTM D882) | Multi-layer durability Withstands 50+ chemical exposures (ASTM D543) | Complex installation process Heavier than single-layer materials |

⭐⭐⭐⭐⭐ James Peterson - Industrial Building Contractor

"We used the Pro Model (2.0mm) for a warehouse roof in northern Scotland, where temperatures dip below -20°C and storms are frequent. After 7 months, the membrane shows zero signs of stress, cracking, or seam leakage. The CE certification gave us confidence for compliance, and the 20m rolls drastically cut our installation time. Worth every penny for heavy-duty applications."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Martinez - Home Builder & Roofer

"Installed the 1.5mm Advanced Model on a flat-roofed townhouse with balcony extensions. The material is incredibly flexible—fit perfectly around curves and drains. We paired it with the manufacturer’s adhesive, and there hasn’t been a single leak during the rainy season. Easy to trim and clean with just mild soap, as recommended. A major upgrade over traditional bitumen felt."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Lin - Underground Infrastructure Team Lead

"Used the 1.2mm Base Model for waterproofing a small utility tunnel in a coastal city. The PVC surface resisted saltwater exposure and root penetration from nearby landscaping—exactly what we needed. Installation was smooth, though I’d recommend extra edge sealing in high-pressure water zones. Overall, a reliable solution for underground projects on a budget."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Anita Clarke - Commercial Property Manager

"We retrofitted an older office building’s roof using the 1.5mm thickness, and the difference is night and day. No more ceiling stains after heavy rain. The soundproofing feature was a surprise benefit—tenants report less noise from rain and HVAC systems. Maintenance staff appreciate the UV resistance; no degradation even after summer heatwaves. Will standardize this across our portfolio."Purchase Date: August 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Marcus Reed - Residential Renovation Enthusiast

"I installed the 1.2mm version on my garage roof myself. The roll was easy to handle, and the material is much lighter than I expected. Cut it to fit the sloped edges without issues. Followed the cleaning advice—just a soft brush and soapy water—and it looks brand new after 5 months. Only reason I didn’t give 5 stars? Wish the adhesive was included or bundled."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Fiona Walsh - Construction Materials Specialist

"Among multi-layer waterproofing membranes, this PVC-asphalt composite stands out for its balanced performance in flexibility, tensile strength, and thermal stability. The 2.0mm variant exceeds EN 13952 standards for roofing membranes, and the CE certification confirms its suitability for EU construction codes. Ideal for projects requiring long-term moisture protection with minimal maintenance."

Carlos Mendez - Senior Waterproofing Advisor

"Having evaluated dozens of membranes, I recommend this product for both retrofit and new-build applications. The 20m roll length reduces seams by nearly a third, which directly lowers leak risks. For residential or mid-tier commercial work, the 1.5mm model offers the best balance of cost and performance."

Posted: 2 days ago

"Used custom-cut pieces for a curved rooftop terrace. The PVC layer held up perfectly during welding. Seamless integration and excellent UV resistance. Client is thrilled."

Posted: 10 days ago

"Installed on three warehouse roofs before monsoon season. Zero leaks reported. The asphalt core adheres tightly to concrete—no bubbling or shifting."

Posted: 3 weeks ago

"Chose the 1.2mm for a residential complex. Cost-effective and durable. Only suggestion: include more installation guides for first-time users."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.