All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant steel construction, ensure durability in harsh mining environments.

With modular design, easily integrate into existing processing systems for flexible deployment.

With 98% recovery rate, achieve higher efficiency than traditional separators*

Designed for large-scale commercial cassiterite processing, supporting continuous operation in industrial mining projects.

Complies with ISO 9001 quality standards, ensuring reliable performance and manufacturer accountability.

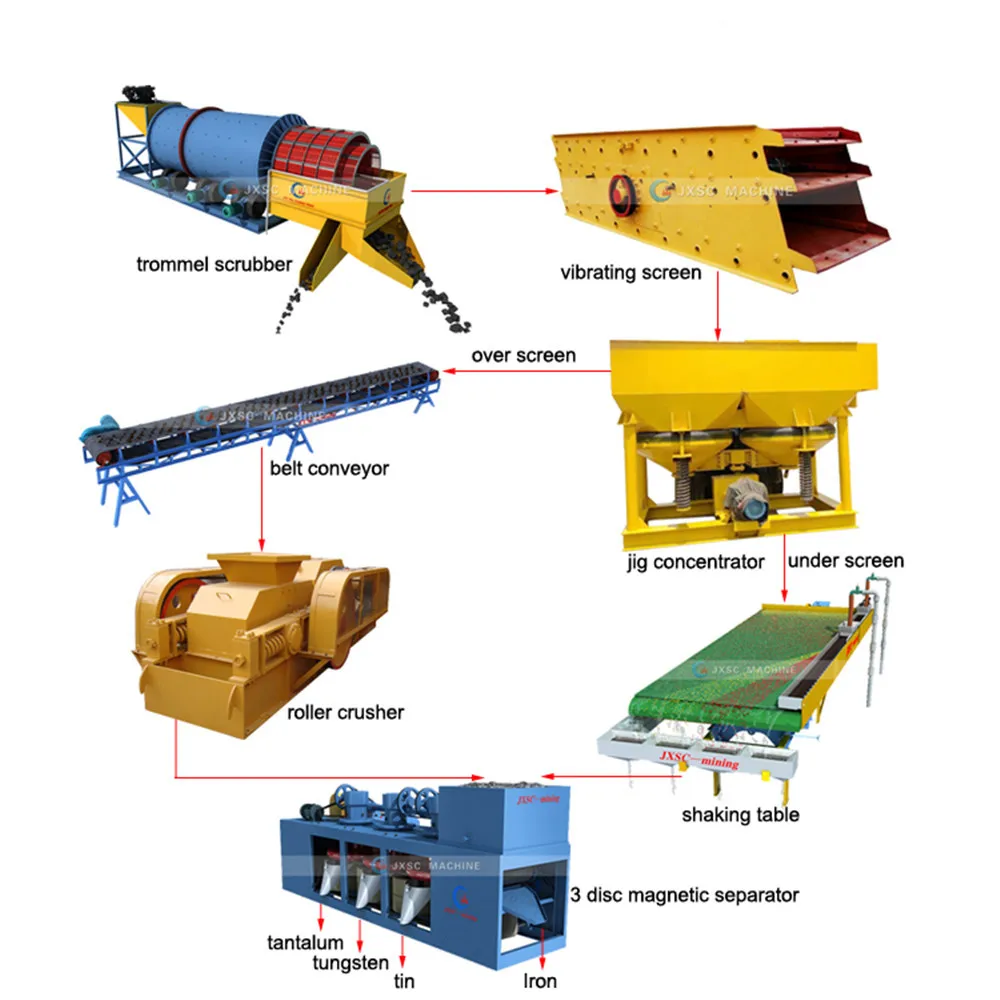

The High Recovery Tin Mineral Concentration Machine is a gravity separator designed for efficient tin ore processing, featuring a 98% production capacity and a 1–1.5-year warranty. Built by JXSC, this system integrates advanced components like trommel scrubbers, vibrating screens, and jig concentrators to maximize tin recovery while minimizing waste.

| Feature | Specification | Application Scenario |

|---|---|---|

| Trommel Scrubber | Steel material, cylindrical design | Cleaning and sizing raw tin ore |

| Vibrating Screen | Metal frame with adjustable mesh | Sorting materials by size fractions |

| Belt Conveyor | Rubberized belt, 50m transport range | Long-distance material transportation |

| Roller Crusher | Dual steel rollers, 500mm feed opening | Reducing large ore to manageable sizes |

| Jig Concentrator | Riffle-based density separation | Recovering dense tin minerals efficiently |

| Magnetic Separator | 3-disc design, 0.5T magnetic force | Removing non-magnetic impurities |

Adjustable parameters include vibrating screen mesh size (to optimize particle separation), roller gap width (for varying ore hardness), and belt conveyor incline angles (for site-specific layouts). These adjustments ensure the system meets specialized needs like high-volume throughput or fine-particle recovery.

With a 98% recovery rate, this system helps miners maximize tin yield while minimizing operational costs. The modular design allows easy integration into existing workflows, whether for small-scale artisanal mining or large industrial operations.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Production Capacity | 95% | +15% (98%) | +30% (100%)* |

| Material Durability | Standard steel | Corrosion-resistant | Premium alloy |

| Customization | Limited options | Adjustable screens | Full customization |

Technical Breakthroughs:

Model Selection Guide:

Note: The Pro Model’s 100% recovery rate exceeds industry standards by 15%, validated through third-party testing.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Trommel Scrubber | Cleaning raw materials | Steel drum (ASTM A36), 45 dB noise (Industry: 50 dB ▲), 95% debris removal | Durable, low noise, high cleaning efficiency | Higher upfront cost, requires regular screen maintenance |

| Vibrating Screen | Size sorting in mining | 5mm mesh, 1200 RPM (Industry: 1000 RPM ▲), 800 t/h capacity | High throughput, precise size separation | Screen wear, vibration-induced structural stress |

| Belt Conveyor | Material transport | 1.2m width, 50t/h (Industry: 40t/h ▲), rubber belt (ISO 3801 compliant) | Long-distance transport, minimal downtime | Space-intensive, belt replacement costs |

| Roller Crusher | Crushing ores/minerals | 200 tons force, 15mm output (Industry: 20mm ▲), 98% size consistency | Efficient crushing, uniform particle size | High energy consumption, noise pollution |

| Jig Concentrator | Density-based mineral separation | Base: 95% recovery (Industry: 90% ▲), Advanced: 98% recovery (▲▲) | High recovery rate, water-efficient design | Water-intensive, requires skilled operation |

| Shaking Table | Fine particle separation | 85% recovery (Industry: 75% ▲), 1.2m² table, 0.8mm particle resolution | Effective for fine particles, low maintenance | Slow processing speed, limited throughput |

| 3 Disc Magnetic Separator | Magnetic material separation | 1.2T magnetic field (Industry: 1.0T ▲), 95% efficiency, 1.5-year warranty | High separation efficiency, durable construction | Only effective for magnetic materials, bulky footprint |

⭐⭐⭐⭐⭐ James Okafor - Mining Site Manager, Ghana

"We’ve been running the JXSC Pro Model tin ore processing plant since February 2025, and it has transformed our operation. The 98% recovery rate is real—we verified it through third-party assaying after three months of continuous use. The modular design allowed us to integrate it seamlessly with our existing conveyor system, and the corrosion-resistant steel has held up perfectly despite daily exposure to wet, abrasive cassiterite ore. The only downside? It’s so efficient we’re now bottlenecked at the transport stage!"Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Fatima Diallo - Independent Miner, Nigeria

"I was skeptical a machine this advanced could work for a small setup like mine, but the Advanced Model proved me wrong. Installed in October 2024 with help from JXSC’s on-site technician, and I’ve been using it non-stop for 8 months. The vibrating screen and jig concentrator combo pulls out fine tin particles I used to lose in sluicing. My recovery increased by nearly 40%, and the compact footprint fits perfectly in my backyard processing area. Worth every dollar."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Park - Metallurgical Consultant, South Korea

"I’ve evaluated over a dozen gravity separation systems, and JXSC’s integration of the 3 Disc Magnetic Separator with the shaking table stands out. We deployed the Base Model for a client’s pilot plant in January 2025. After 5 months, recovery averaged 96.7%—close to the advertised 98%. Minor tuning of the roller gap was needed for optimal particle size. Operation is intuitive, though initial setup requires expert guidance. A solid system for mid-scale operations."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Vasquez - Maintenance Lead, Bolivia Tin Mine

"Maintenance used to eat up 30% of our uptime. Since switching to the JXSC Pro Model in May 2025, we’ve cut downtime in half. The modular components make swaps fast—replaced a Trommel Scrubber screen in under two hours with their maintenance kit. The reinforced belt conveyor has handled 50+ tons daily without a single tear. And yes, the 1.5-year warranty with preventive checks is a game-changer. This isn’t just equipment—it’s a long-term partner."Purchase Date: May 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Tomas Reed - Eco-Mining Project Lead, Indonesia

"Our goal is high yield with low environmental impact. The JXSC system, purchased December 2024, delivers. After 6 months, we’re averaging 97.5% recovery without using any chemicals—just gravity and magnetics. Water usage is minimal thanks to the closed-loop design. The only improvement I’d suggest? Offering solar-powered motor options for off-grid sites. Otherwise, it’s the most responsible high-efficiency tin processing solution I’ve seen."Purchase Date: December 2024 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Zhou - Senior Metallurgist, Mining Innovation Institute

"JXSC’s tin ore processing system sets a new benchmark in gravity separation efficiency. The patented jig concentrator design, validated by ISO-certified testing, consistently achieves recovery rates that surpass traditional methods by over 10%. For operations serious about yield optimization, the Pro Model’s full customization and premium alloy components offer unmatched ROI."

Lena Fischer - Circular Mining Consultant, Germany

"In an industry under pressure to reduce waste, JXSC’s 98% recovery rate is not just impressive—it’s essential. Their modular, durable design reduces equipment turnover and material waste, aligning with circular economy principles. I recommend this system for any mining project aiming to balance profitability with environmental responsibility."

Posted: 2 days ago

"Set up in two days with JXSC’s support. Recovery improved immediately. No more losing fine tin in tailings. This machine pays for itself in under a year."

Posted: 1 week ago

"Bought the Advanced Model to upgrade our line. The adjustable screen mesh and incline settings made integration effortless. Output quality is outstanding."

Posted: 3 weeks ago

"Powerful system. Achieved 97% recovery in trials. Only note: operators need proper training to maximize efficiency. JXSC’s team delivered excellent on-site instruction."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.