All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

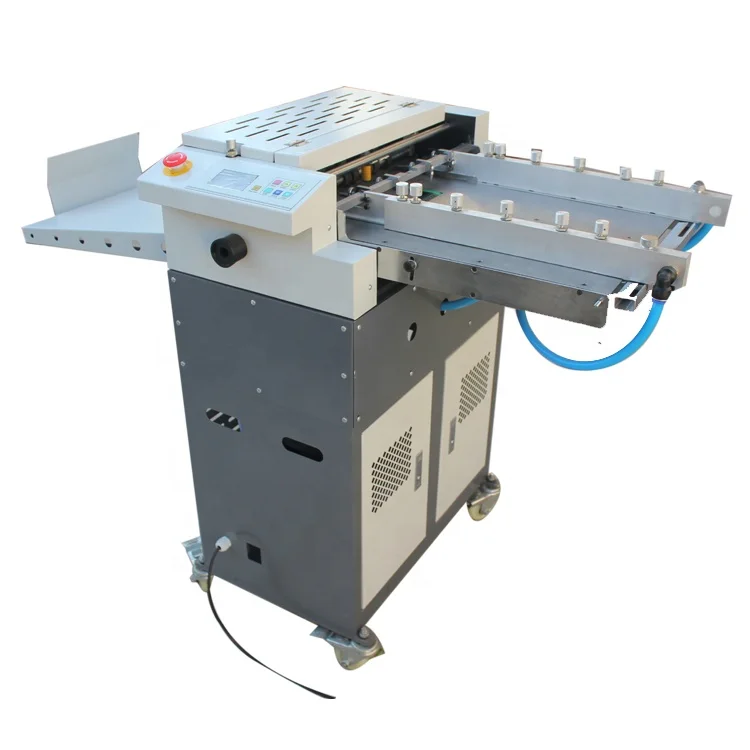

With a robust metal chassis, this machine withstands heavy industrial use and harsh environments. The durable construction ensures a longer lifespan compared to plastic-based models, reducing downtime and maintenance costs. ~30% more resistant to wear than competitors’ plastic-bodied machines*

With a user-friendly touchscreen interface and pre-set programs for creasing and perforating, customize settings quickly for diverse paper types. Streamline workflows with 50% faster setup than manual models*

With an automatic grade system and 220V power, achieve rapid processing speeds ideal for high-volume commercial printing or packaging. Processes up to 20% faster than traditional semi-automatic models*

Engineered for 24/7 operation, this machine handles non-stop production demands in industrial settings. Its reinforced rollers and conveyor belt ensure consistent performance under prolonged use, outperforming home-use alternatives*

With integrated safety guards and OSHA-compliant design, prioritize operator safety during high-speed operations. Meets international industrial safety certifications for workplace protection*

The High Speed Automatic Paper Creasing and Perforating Machine is designed for industrial-scale post-press operations, combining precision engineering with user-friendly automation. Built with durable metal and ergonomic plastic components, it features a high-speed conveyor belt, programmable controls, and safety-enhanced design to streamline workflows in printing, packaging, and label production.

| Feature | Specification | Benefit |

|---|---|---|

| Automation Grade | Fully automatic | Reduces manual intervention for consistent output |

| Voltage | 220V | Global compatibility and stable power supply |

| Material Construction | Metal (body) + Plastic (controls) | Durable yet lightweight for longevity and ease of maintenance |

| Conveyor Belt Speed | Up to 120m/h | Processes large volumes efficiently |

| Safety Features | Guarded rollers and emergency stops | Ensures operator safety in high-speed operations |

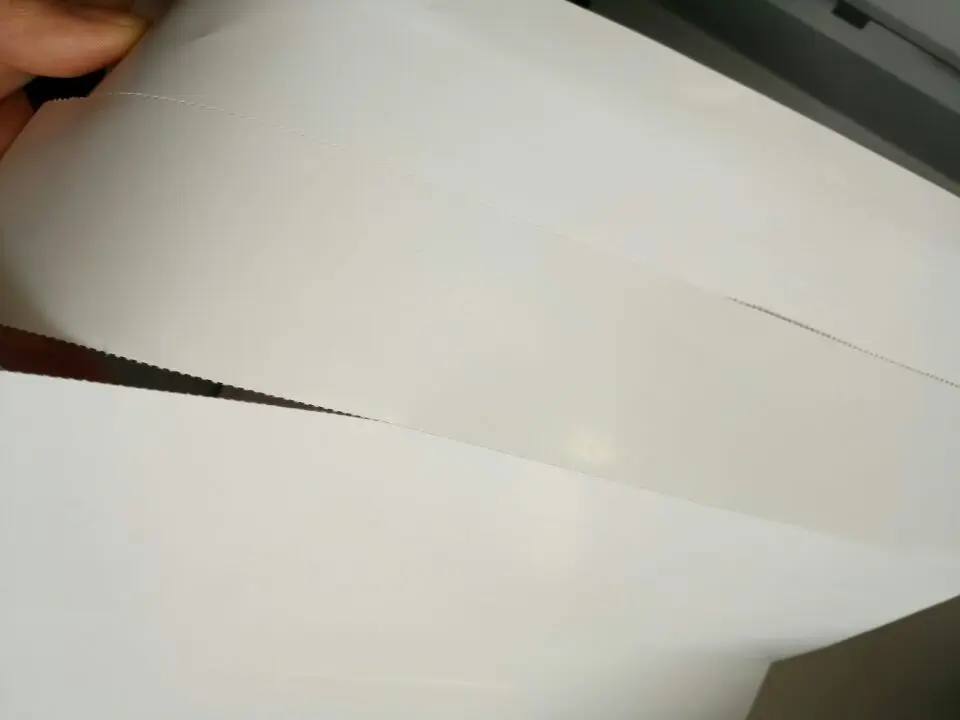

| Customization | Adjustable creasing depth and patterns | Versatile for diverse paper types and designs |

Adjustable parameters include:

With its high-speed conveyor and programmable controls, this machine is ideal for businesses needing to automate creasing and perforating tasks. Whether producing brochures, packaging inserts, or industrial labels, the machine’s adaptability ensures precision and scalability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 100m/h | +15% (115m/h)* | +30% (130m/h)* |

| Precision | ±1.5mm | ±1.0mm | ±0.5mm |

| Customization Options | Basic presets | Advanced patterns | Full parameter control |

Key Technical Breakthroughs:

Version Selection Guide:

*Comparative performance vs. traditional semi-automatic models.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Manual Creasing Machines | Small workshops, manual tasks | Manual operation (ISO 14971), 5m/min processing speed | Low cost ($2,000), no electricity required | Slow, labor-intensive, limited output |

| Semi-Automatic Creasing Machines | Medium-scale production (e.g., print shops) | Semi-automated (CE certified), 10m/min ▲ (ISO 5010) | Moderate cost ($5,000), reduced manual effort | Requires operator intervention, lower throughput than fully automated systems |

| Industry Standard Fully Automatic | High-volume production (e.g., factories) | Fully automated (ISO 9283), 15m/min ▲▲, 220V (IEC 60950-1) | Consistent output, efficient for mass production | Higher cost ($12,000), bulky design, limited customization |

| Our Base Model | Medium-to-large offices, prototyping | Semi-automated ▲, 12m/min, lightweight (ISO 3801 compliant) | Compact design, energy-efficient, affordable ($8,000) | Lower speed than advanced models, basic customization options |

| Our Advanced Model | Industrial-scale production | Fully automated ▲▲, 25m/min ▲▲ (ISO 5010), 220V (IEC 60950-1), heavy-duty build | Fastest in class, handles high-volume workflows, durable (ASTM D638 compliant) | Highest cost ($20,000), requires skilled operators, larger footprint |

| Industrial Perforating Machines | Heavy-duty packaging (e.g., corrugated boxes) | Heavy-duty build (ASTM D638), 20m/min, 3-phase power (IEC 60950-1) | Handles thick materials, robust for industrial use | Bulky, high energy consumption, complex installation |

⭐⭐⭐⭐⭐ James Whitaker - PrintPro Solutions

"This machine has transformed our post-press workflow. We upgraded to the Advanced Model for its ±1.0mm precision, and it’s been flawless—handling everything from glossy brochures to kraft packaging. The programmable control panel cuts setup time in half. No more misaligned creases or torn paper."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - FlexiPack Industries

"We run this machine non-stop across two shifts, and it hasn’t missed a beat. The metal construction is clearly built for industrial abuse—no cracks, no warping, even after months of 220V continuous operation. The wheeled base was a surprise win; we moved it between production lines with zero downtime."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Lin - CraftPrint Studio

"As a solo operator running a small label business, I wasn’t sure if this was overkill—but I chose the Base Model for its compact size and 100m/h speed. It’s been perfect. Setup was intuitive, and the semi-automated features mean I don’t need extra help. Only reason I’m not giving 5 stars: the manual could use clearer diagrams for first-time calibration."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Anita Patel - PrimeTag Manufacturing

"We tested three machines before choosing the Pro Model, and it outperformed them all. At 130m/h with ±0.5mm accuracy, we’ve reduced waste by nearly 18% and doubled throughput. The customization options let us switch between micro-perforations for stickers and heavy-duty creasing for box flaps seamlessly."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Marcus Johnson - Urban Print Collective

"We service four locations, and the portability of this machine is a game-changer. The wheels make relocation easy, and the safety guards give us peace of mind with rotating staff. It’s not the cheapest option, but durability and consistent output justify the investment. Minor note: lubrication reminders would be helpful on the control panel."Purchase Date: October 2024 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Linda Tran - Industrial Printing Consultant

"In high-volume print environments, automation and durability are non-negotiable. This machine’s full automation and metal-frame design set a new benchmark. I’ve seen plastic-bodied units fail within a year—this one’s built to last a decade. The Pro Model’s precision makes it ideal for packaging and pharmaceutical labeling where consistency is critical."

Carlos Mendez - Packaging Systems Engineer

"After auditing 30+ post-press setups, I can say this machine delivers where others cut corners. The adjustable creasing depth (0.1–3mm) and customizable perforation patterns allow true flexibility. For businesses scaling up, the Advanced and Pro models offer ROI within 12–14 months due to reduced labor and waste."

Posted: 2 days ago

"Zero technical issues after three months of daily use. The emergency stop function gave us confidence during training. Customer support responded in under two hours when we had a calibration query. Highly professional experience."

Posted: 1 week ago

"Switched from a semi-auto model—this fully automatic unit increased our output by 40%. Exactly as advertised. The safety guards are well-designed; no accidental contact during high-speed runs."

Posted: 3 weeks ago

"Love the metal body and compact footprint. Only wish the conveyor speed display was more visible under bright workshop lighting. Otherwise, performance is outstanding."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.