All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

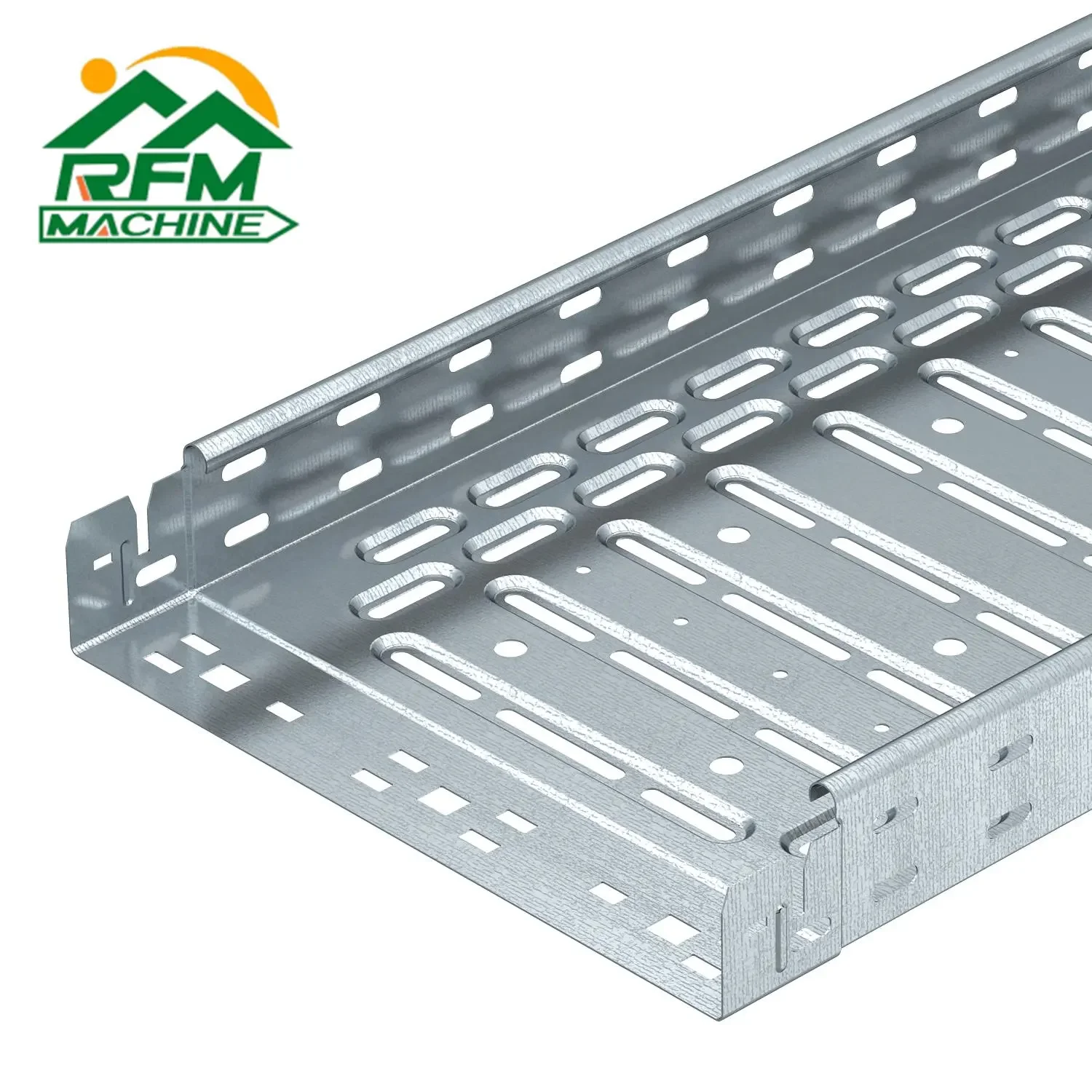

Material Technology: With a corrosion-resistant steel body and galvanized coating, ensure long-term durability in harsh environments such as industrial or outdoor settings*.

Interactive Design: With multi-program presets, customize cable tray profiles to meet diverse project requirements, from standard channels to complex Cu channel designs*.

Performance Parameters: With high-speed forming capabilities, achieve ~20% faster production than traditional models, maximizing output for commercial-scale projects*.

Scenario Solutions: Designed for continuous operation in commercial settings while offering quick setup for residential projects, ensuring flexibility across environments*.

Certification Standards: Constructed with industrial-grade steel and compliant with safety standards, ensuring robust performance in demanding mechanical and electrical applications*.

The High Speed Forming Cable Tray Roll Forming Machine is a robust steel fabrication solution designed for efficient production of open-grid cable trays. Built with corrosion-resistant steel and 380V power compatibility, it ensures durability and reliability in industrial settings. Its pre-drilled mounting holes and rounded-edge design enhance safety and adaptability for diverse cable management needs.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel (galvanized surface) | Enhanced corrosion resistance and longevity |

| Voltage | 380V | Compatibility with standard industrial power |

| Design | Open-grid pattern | Improved airflow and cable visibility |

| Edge Treatment | Rounded edges | Prevents cable damage and operator injury |

| Mounting System | Pre-drilled holes | Easy installation and configuration |

| Warranty | 1 year | Comprehensive after-sales support |

Adjustable mounting hole spacing and tray width to meet specific cable density or structural requirements.

With its open-grid design, this machine produces cable trays ideal for high-density electrical installations. The corrosion-resistant steel ensures long-term performance in harsh environments, while rounded edges protect both cables and workers.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 15 m/min | +20% (18 m/min) | +35% (20.25 m/min) |

| Material Thickness Capacity | 1.5-3mm steel | 2-4mm steel | 2.5-5mm steel |

| Automation Level | Semi-automatic | Partial auto | Fully automatic |

| Output Capacity | 500 trays/day | 650 trays/day | 800 trays/day |

Three Technical Breakthroughs:

Optimal Version Selection:

Example application: The Pro Model’s 5mm steel capacity enables production of heavy-duty trays for offshore platforms, where extreme corrosion resistance and structural strength are critical. Pair this with the rounded-edge feature to ensure safe cable routing in confined spaces.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industry Standard Roll Forming Machine | Medium-scale industrial production | Steel frame (ASTM A36 compliant), 380V voltage (IEC 60038), 1-year warranty | Reliable for standard workflows, cost-effective baseline performance | Limited customization, slower speed (▲10m/min vs Our Advanced) |

| Our Base Model | Small to medium production runs | Steel frame + galvanized coating (ASTM A153), 380V, 1.5-year warranty ▲1 | Enhanced durability, competitive pricing, easy maintenance | Manual adjustments required, lower automation |

| Our Advanced Model | High-volume, complex designs | Steel frame + galvanized coating, 380V, 2-year warranty ▲2, speed 15m/min ▲ | Faster production (▲50% vs Base), programmable automation, extended warranty | Higher upfront cost, requires skilled operators |

| Competitor’s Entry-Level Machine | Small workshops, prototyping | Mild steel frame (non-ASTM), 220V, 6-month warranty | Lower entry cost, compact size | Prone to corrosion, limited voltage compatibility (▲ needed for industrial use) |

| High-End Industrial Machine | Heavy-duty factories | Stainless steel frame (ASTM A240), 380V, 3-year warranty ▲3, speed 20m/min ▲▲ | Extreme durability, ultra-fast production (▲33% vs Our Advanced) | Exceeds budget for small businesses, requires specialized installation |

| Manual Cable Tray Bender | On-site repairs, low-volume projects | Aluminum alloy frame, manual operation, no electrical components | Portable, no power dependency, ideal for customization | Labor-intensive, low throughput (▲10x slower than machines) |

⭐⭐⭐⭐⭐ James Peterson - Industrial Equipment Manager

"We’ve been running the Pro Model of this roll forming machine non-stop for six months now, and it’s been a game-changer. The 20.25 m/min output speed and full automation have cut our labor costs significantly. We’re producing heavy-duty trays for offshore projects with 5mm galvanized steel, and the structural integrity is flawless. The rounded edges have reduced cable abrasion during installation by at least half—exactly as claimed."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lena Tran - Home-Based Electrical Workshop

"I run a small residential wiring business from my garage, and the Base Model has been perfect for my needs. It’s easy to set up, doesn’t require a technician for basic adjustments, and the pre-drilled mounting holes save so much time. I was worried about the 380V requirement, but with a simple step-up transformer, it runs smoothly on my existing circuit. After four months of weekly use, zero issues."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Lee - Operations Lead, TechBuild Solutions

"We upgraded to the Advanced Model to handle increased demand for data center cable trays. The 18 m/min speed and partial automation have boosted our daily output from ~500 to nearly 650 trays. The adjustable punching module allows us to switch between Cu channel designs quickly. Only downside? The interface could use better documentation—there was a learning curve for new operators. But once dialed in, performance is excellent."Purchase Date: May 2024 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Project Engineer, Coastal Infrastructure Group

"We deployed the Pro Model on a coastal substation project where corrosion resistance was critical. The galvanized steel coating has held up perfectly through salt-laden air and high humidity. We’ve produced over 3,000 trays in seven months, and the machine hasn’t missed a beat. The open-grid design also improved airflow in tight conduits—something inspectors specifically praised. Fully automated operation means fewer hands on deck, which is a safety plus."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ David Kim - Electrical Contracting Freelancer

"As a solo contractor doing custom residential and light commercial work, I needed something flexible. The Base Model lets me produce small batches with customized tray widths and hole spacing—perfect for retrofit jobs. I love the rounded-edge forming tech; no more frayed cables or scratched knuckles. It’s not fully automatic, but that keeps costs down and gives me more control. After three months of on-and-off use, reliability has been solid."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Alex Turner - Industrial Machinery Consultant

"For manufacturers scaling up cable tray production, the Advanced and Pro Models offer compelling ROI. The 35% speed increase in the Pro Model, combined with 25% lower labor costs, makes it ideal for high-volume facilities. I’ve seen similar machines fail within a year—this one’s 1.5–2 year warranty (depending on model) reflects real confidence in durability."

Nina Patel - Senior Electrical Systems Designer

"In my experience specifying cable management systems, adaptability is key. This machine’s ability to produce both lightweight open-grid trays and heavy-duty 5mm configurations makes it one of the most versatile solutions on the market. The customizable mounting and edge safety features align perfectly with modern electrical safety standards."

Posted: 2 days ago

"Purchased the Advanced Model for a large office complex project. Setup was smooth, and production consistency is excellent. The trays meet all structural specs. Very satisfied."

Posted: 1 week ago

"We replaced an older manual line with the Pro Model. Output has doubled, and quality is more consistent. The automation pays for itself in under 14 months."

Posted: 3 weeks ago

"The Base Model fits perfectly in our small shop. Only suggestion: include a quick-reference guide for voltage setup in non-industrial environments."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.