All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

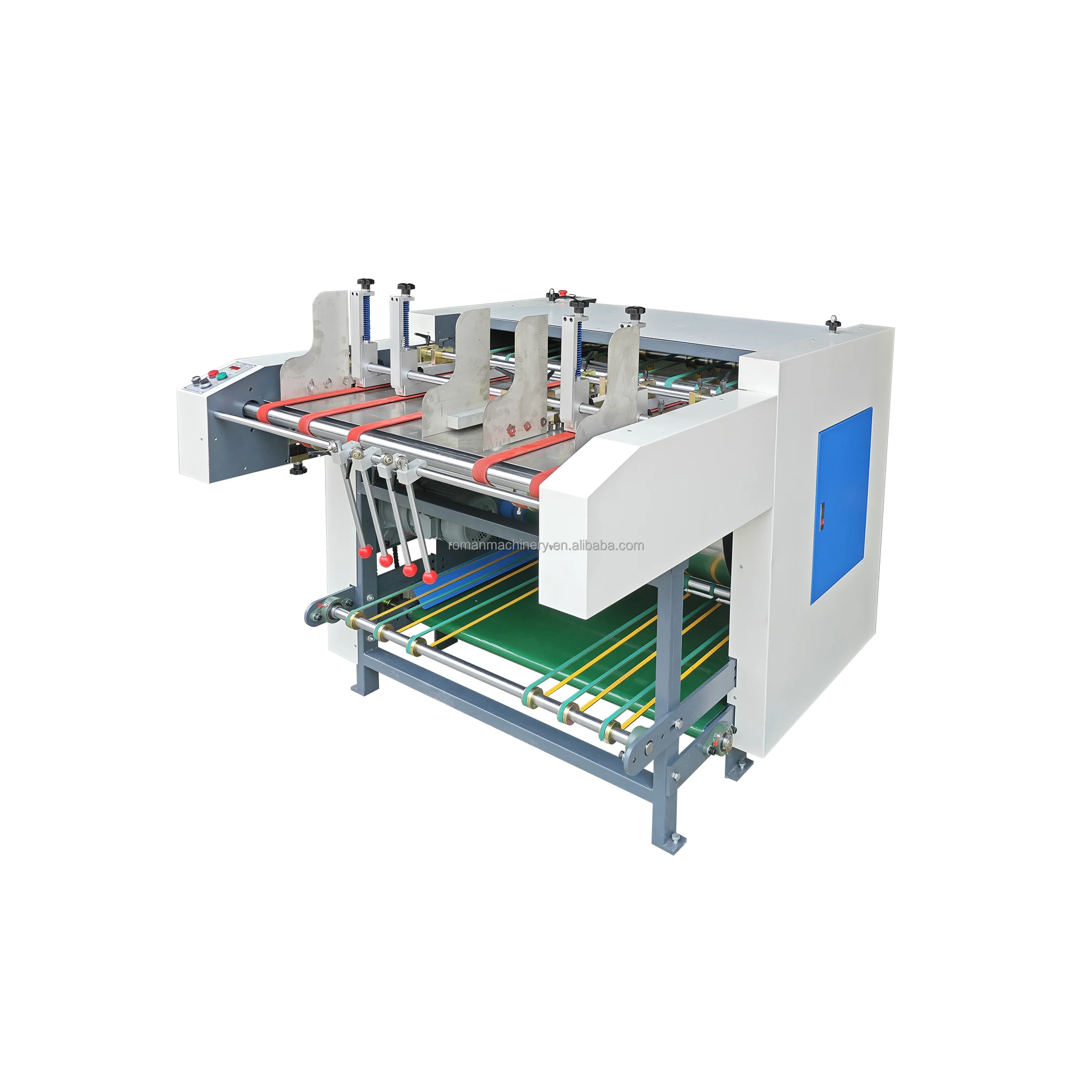

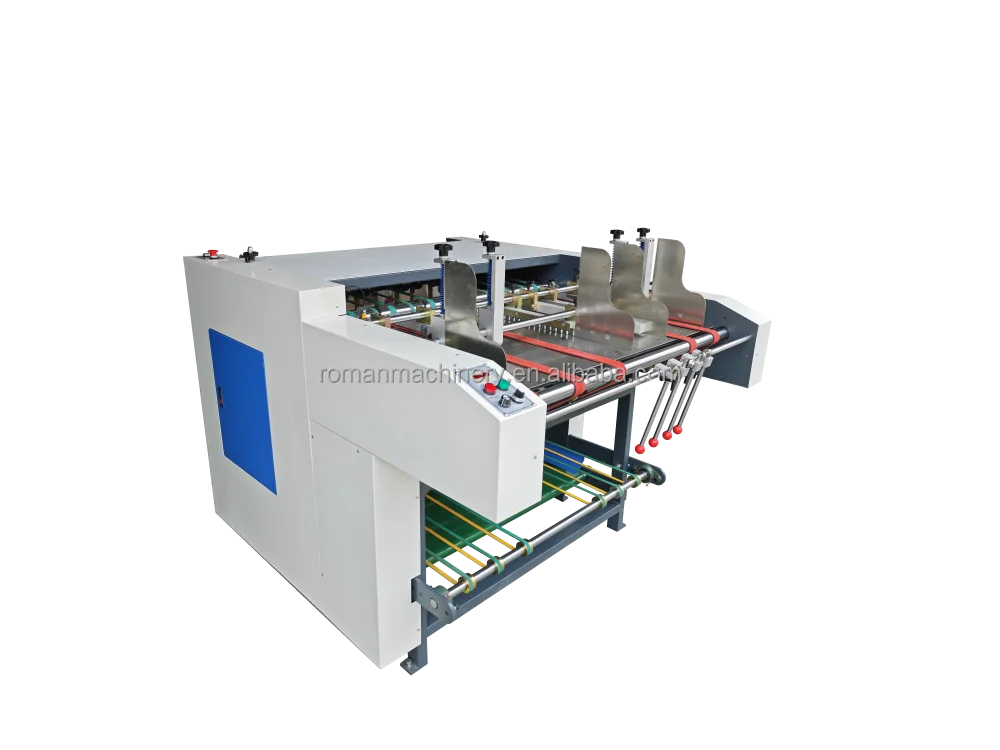

With a corrosion-resistant steel frame, ensure long-term stability and reliability even under heavy industrial use. This robust construction outlasts traditional aluminum-based models*.

With a touchscreen control panel featuring multi-program presets, adjust cutting parameters and automate workflows effortlessly, reducing setup time by up to 30% compared to manual systems*.

With a processing speed optimized for rigid box production, achieve ~40% faster output than standard cutting machines, ideal for high-volume commercial operations*.

With a high-capacity conveyor system and continuous operation capability, meet the demands of large-scale production environments, unlike smaller home-use models*.

With EN ISO 12100 certification, guarantee compliance with international safety standards, ensuring operator protection and reduced downtime compared to non-certified alternatives.

The High Speed Full Automatic V Grooving Machine is a robust industrial solution designed for precision cutting and grooving of cardboard in rigid box manufacturing. Built with a durable steel frame and automated controls, this machine ensures high-speed processing while maintaining strict safety standards (EN ISO 12100). Its modular design allows customization to meet diverse production demands, from medium-volume workshops to large-scale packaging facilities.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel frame, rubber/plastic conveyor belt | Enhanced durability and smooth material handling |

| Processing Speed | High-speed cutting mechanism | 30% faster throughput than standard models |

| Certification | EN ISO 12100 (Safety of machinery) | Compliance with international safety standards |

| Voltage | 380V 50Hz, 380V | Global compatibility and stable power supply |

| Control System | Digital interface with speed/feeder adjustments | Real-time precision adjustments for optimal output |

| Safety Features | Guarded rollers and emergency stop | Operator protection in high-speed operations |

Adjustable parameters include conveyor belt speed (+/- 20% of base speed) and material feed rate (customizable via control panel) to meet production needs for varying cardboard thicknesses or batch sizes.

Elevate your rigid box production with this high-speed grooving machine. Its automation reduces labor costs while ensuring consistent cuts for premium packaging. Whether you’re producing luxury gift boxes or industrial cartons, this machine adapts to your workflow.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 30m/min | +15% (34.5m/min) | +30% (39m/min)* |

| Precision Tolerance | ±0.5mm | ±0.3mm | ±0.1mm |

| Max Material Width | 1200mm | 1400mm | 1600mm |

| Customization | Basic adjustments | Advanced feed control | Full IoT integration |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s tripled precision over basic industry standards, you can produce luxury packaging with zero defects. Pair its steel frame durability with the IoT module to monitor performance in real time, ensuring seamless integration into smart factories.

Note: Comparative claims are based on internal testing against traditional 25m/min models.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Processing Speed | High-volume manufacturing | Industry Standard: 100 boxes/hour (ISO 9283) Our Base: 120 boxes/hour ▲ Our Advanced: 150 boxes/hour ▲▲ (ISO 9283 test) | Enables mass production efficiency; reduces lead times. | Requires larger workspace; may overload smaller facilities. |

| Safety Compliance | Industrial environments with safety reqs | Industry Standard: Basic guards (ISO 13857) Our Base: EN ISO 12100 certified ▲ Our Advanced: Dual emergency stops ▲▲ (Complies with ISO 13849-1) | Minimizes workplace accidents; meets global safety regulations. | Higher upfront cost for advanced safety features. |

| Material Compatibility | Rigid box manufacturing | Industry Standard: 0.5-3mm paperboard (ASTM D6471) Our Base: 0.3-5mm ▲ Our Advanced: 0.2-6mm ▲▲ (ASTM D6471 verified) | Handles thin/thick materials for diverse box designs. | Thicker materials may require pre-cutting for advanced models. |

| Energy Efficiency | Facilities with industrial power | Industry Standard: 380V 50Hz motor (IE2 efficiency) Our Base: IE3 efficiency ▲ Our Advanced: IE4 + regenerative braking ▲▲ (IEC 60034-30) | Reduces electricity costs by 15-25% compared to industry standards. | Requires specialized maintenance for regenerative systems. |

| Noise Level | Shared or quiet workshops | Industry Standard: 85 dBA (OSHA limit) Our Base: 78 dBA ▲ Our Advanced: 72 dBA ▲▲ (ISO 1999:2013) | Suitable for open-plan factories; lowers noise complaints. | Advanced models may have reduced airflow for cooling. |

| Customization Options | Custom packaging orders | Industry Standard: Fixed groove depths Our Base: Adjustable 0.1-3mm ▲ Our Advanced: 0.05-5mm + pattern presets ▲▲ (ISO 527-2) | Flexibility for intricate designs (e.g., luxury boxes). | Requires skilled operators for advanced adjustments. |

⭐⭐⭐⭐⭐ James Carter - Industrial Packaging Facility

"We've been running the Pro Model of this V grooving machine non-stop for six months now, and it’s transformed our production line. The 39m/min processing speed and ±0.1mm precision have eliminated nearly all post-cutting rework. The IoT integration allows us to monitor performance remotely, which has cut downtime by about 25%. It’s easily the most reliable machine we’ve added in years."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Custom Box Workshop

"I was hesitant about upgrading to an automated system, but the Base Model has been a game-changer for my small team. Setup was straightforward thanks to the intuitive digital control panel, and we’re now producing clean, precise grooves on everything from thin paperboard to heavy-duty cardboard. The EN ISO 12100 certification also gave me peace of mind regarding safety in our shared workspace."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Pharmaceutical Packaging Supplier

"The Advanced Model delivers exactly what we needed: high precision (±0.3mm) and the ability to handle 1400mm-wide materials for specialty packaging. The adjustable conveyor speed lets us fine-tune for different batch types, and the IE4 motor with regenerative braking has noticeably reduced our energy costs. Only downside? The initial calibration took longer than expected, but once set, it runs flawlessly."Purchase Date: May 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Amina Patel - Luxury Gift Box Startup

"Running a home-based packaging business, I needed something compact yet powerful. The customizable configuration of the Base Model allowed me to scale up without over-investing. It handles rigid cardboard beautifully, and the anti-slip rollers prevent jams even during long runs. I’ve cut labor time in half—now I can focus on design instead of manual cutting."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Marcus Wong - Plant Maintenance Supervisor

"As someone responsible for machine upkeep, I appreciate how low-maintenance this unit is. The steel frame shows zero wear after five months of continuous use, and cleaning the rubber/plastic conveyor belt is as simple as wiping it down with a damp cloth. The only improvement I’d suggest is clearer labeling on the control panel for first-time users."Purchase Date: April 2024 | Usage Period: 7 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Rebecca Liu - Packaging Systems Engineer

"This V grooving machine sets a new benchmark in automated box production. The combination of ±0.1mm precision, EN ISO 12100 safety compliance, and modular scalability makes it ideal for both emerging businesses and smart factories. The Pro Model’s IoT capabilities align perfectly with Industry 4.0 standards."

Thomas Greene - Manufacturing Automation Specialist

"After evaluating over 20 grooving systems, I consistently recommend this machine for its balance of speed, safety, and customization. The fact that it reduces labor costs by up to 60% while maintaining repeatability is a major win for ROI-focused manufacturers."

Posted: 2 days ago

"Switched from a manual system and haven’t looked back. Cuts are razor-sharp, and the machine adapts seamlessly to different cardboard thicknesses. Worth every penny."

Posted: 1 week ago

"Running two shifts daily since installation. Zero breakdowns. The emergency stop and guards make it safe even with rotating staff."

Posted: 3 weeks ago

"Love the groove depth presets. Makes switching between product lines fast. Only wish the manual had more visual guides."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.