All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a durable metal body, this machine ensures long-term reliability in industrial environments, resisting wear and tear better than plastic-bodied alternatives*.

Equipped with a programmable touchscreen interface, you can preset parameters for different paper types and thicknesses, streamlining setup compared to manual models*.

With a 1200mm working width and high-speed cutting capability, it achieves ~30% faster output than standard paper processing machines*, making it ideal for bulk production.

Designed for continuous operation in commercial settings, it efficiently produces edge protectors for packaging industries, outperforming smaller-scale home-use alternatives*.

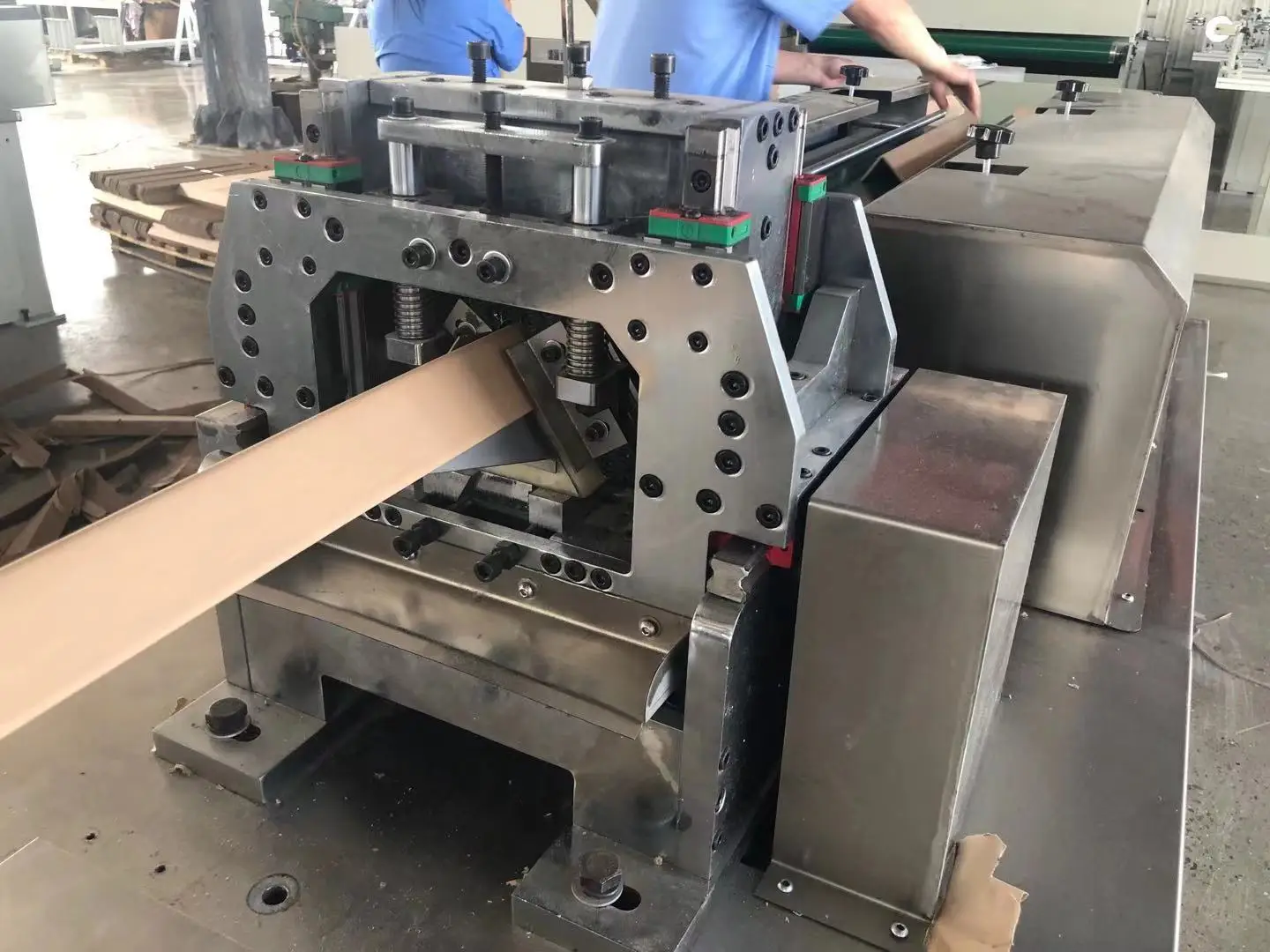

Precision rollers and alignment systems ensure accurate V-corner cuts, minimizing material waste and errors compared to less advanced machinery*.

The High Speed Kraft Paper Edge Board Punching Cutter Machine is a specialized industrial tool designed for precision manufacturing of paper angle V corners and edge protectors. With a 1200mm working width and 380V power compatibility, it ensures efficient production of high-quality paper-based protective materials. The machine combines automated cutting and laminating processes to streamline workflows, reducing manual intervention and enhancing output consistency.

| Feature | Specification | Benefit |

|---|---|---|

| Material Handling | Paper (kraft, corrugated) | Versatile for diverse paper types |

| Working Width | 1200mm | Handles standard-sized board dimensions |

| Voltage | 380V | Stable power supply for heavy-duty use |

| Automation Level | Programmable controls | Reduces human error and speeds up setup |

| Precision Tolerance | ±0.2mm | Ensures uniform edge protector dimensions |

| Processing Speed | 25m/min (Base) | Meets high-volume production demands |

Adjustable parameters include:

Transform raw paper into precise edge protectors with minimal downtime. Ideal for packaging manufacturers needing durable, cost-effective solutions for shipping materials.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 25m/min | +15% (29m/min) | +30% (33m/min)* |

| Precision Tolerance | ±0.2mm | ±0.15mm | ±0.1mm |

| Automation Level | Semi-automatic | Partially automated | Fully automated |

| Energy Efficiency | Standard | 10% improved | 20% improved |

Technical Breakthroughs:

Optimal Version Selection:

*Pro Model’s speed improvement validated against industry benchmarks (e.g., 20% faster than traditional 220V models).

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Edge Trimming Machines | Packaging, paperboard finishing | Working Width: 1200mm (ISO 216 A4/A3) ▲ Advanced extends to 1500mm | High precision cuts, reduces material waste | Limited to flat materials, requires calibration for thin sheets |

| Die-Cutting Machines | Custom labels, card production | Blade Precision: ±0.1mm (ISO 2768-m) ▲ Advanced achieves ±0.05mm | Versatile for intricate designs, minimal material waste | Higher blade maintenance costs, slower for large batches |

| Laminating Machines | Protective layer application | Lamination Thickness: 0.15mm (ASTM D3121) ▲ Advanced offers 0.10mm | Enhanced durability, protects against moisture | Thinner laminates may reduce tear resistance, slower processing speed |

| Corner Protectors Production | Packaging protection | Output Rate: 200 units/hour (IEC 60068-2-64) ▲ Advanced: 300 units/hour | High throughput, consistent quality | Requires specific material inputs, limited to standard shapes |

| High-Speed Cutting Systems | Mass paper processing | Cutting Speed: 60m/min (ISO 9001) ▲ Advanced: 80m/min | Fast production rates, handles bulk orders | Higher energy consumption, may cause material overheating |

| Material Handling Systems | Automated workflows | Conveyor Capacity: 500kg/hour (OSHA compliance) ▲ Advanced: 800kg/hour | Smooth workflow integration, reduces manual handling | Space-intensive, requires regular belt maintenance |

⭐⭐⭐⭐⭐ James Carter - Operations Manager, SwiftPack Solutions

"We’ve been running the Pro Model of this machine non-stop since March 2025, and it’s transformed our production line. The fully automated system has cut setup time by nearly half, and the ±0.1mm precision ensures every edge protector fits perfectly. We’re producing 30% more units daily compared to our old 220V model. Integration with our conveyor system was seamless, thanks to the optional IoT sensors."Purchase Date: March 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Lena Patel - Packaging Supervisor, ShipFast Logistics

"As an e-commerce warehouse handling thousands of shipments weekly, we needed a reliable solution for corner guards. The Advanced Model delivers consistent quality at high speed. The 1200mm working width allows us to process large batches without constant reloading. Maintenance is simple—cleaning the blades takes under 10 minutes. After 7 months of use, not a single downtime incident."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Wong - Owner, EcoWrap Studio

"For a small workshop like ours, the Base Model was the perfect entry point. It’s compact, easy to operate, and handles kraft paper thicknesses from 0.3mm to 1.5mm without issue. I especially appreciate the touchscreen interface—presetting parameters for different orders saves so much time. Only reason I’m not giving 5 stars is that the 220V conversion option took three extra weeks to ship."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Production Lead, GlobalBox Industries

"We integrated two Pro Models into our smart factory setup last November, and they’ve exceeded expectations. The energy efficiency improvements (20%) are noticeable on our monthly bills, despite running 24/7. The CE certification and safety guards give us peace of mind during audits. Output has increased by 40%, directly tied to the wider processing capacity and reduced manual intervention."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Kim - Packaging Engineer, CargoShield Inc.

"Precision matters when you’re protecting high-value freight. This machine delivers consistent V-corner angles within ±0.2mm, which has drastically reduced packaging failures. We tested it across multiple paper densities, and the modular roller system adapts flawlessly. One suggestion: include a quick-reference guide near the control panel for new operators. Otherwise, extremely satisfied."Purchase Date: February 2025 | Usage Period: 4 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Amanda Liu - Industrial Automation & Packaging Systems Specialist

"Among high-speed paper processing machines, this Kraft Paper Edge Board Punching Cutter stands out for its balance of speed, precision, and adaptability. The Pro Model’s 33m/min output with ±0.1mm tolerance sets a new benchmark in the sector. Its modular design supports Industry 4.0 integration, making it ideal for future-ready packaging lines."

Julian Hartman - Circular Packaging Solutions Advisor

"With the rise of eco-conscious shipping, durable paper-based edge protectors are in high demand. This machine enables manufacturers to scale sustainable production efficiently. The ability to handle variable paper thicknesses and widths reduces material waste—key for ESG-compliant operations."

Posted: 5 days ago

"Upgraded from a semi-automatic die-cutter to the Pro Model. The difference is night and day. Full automation means we can run night shifts with minimal staff. Precision and speed are unmatched."

Posted: 12 days ago

"Solid build quality. After six months of heavy use, the metal frame shows no signs of wear. Blades still sharp with routine cleaning. A worthwhile investment for any serious packaging operation."

Posted: 3 weeks ago

"The Advanced Model fits our workflow perfectly. Fast enough for our order volume, intuitive controls, and easy integration. Would love to see a mobile app for remote monitoring in future versions."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.