All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

Material Technology

Interactive Design

Performance Parameters

Scenario Solutions

Certification Standards

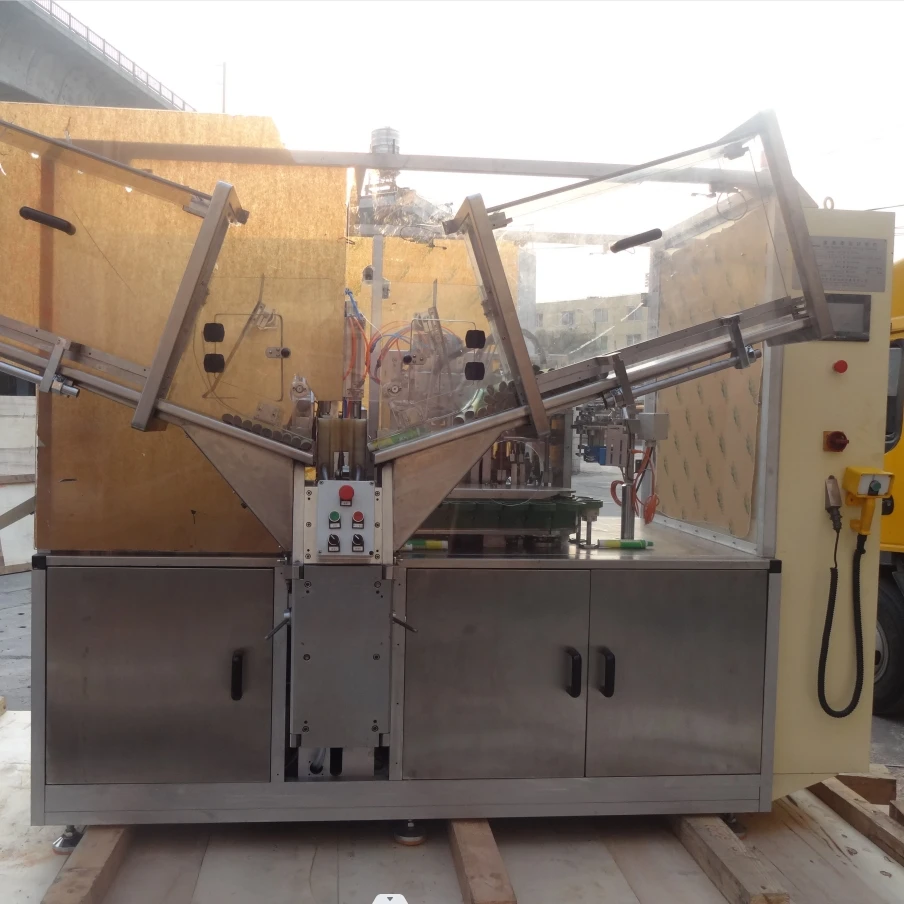

The High Speed Packaging Machinery Automatic Aluminium Plastic Tube Filler and Sealer is a versatile industrial solution designed for precise filling and sealing of viscous liquids, powders, and granules into tubes, jars, and other containers. Built with corrosion-resistant stainless steel and featuring programmable controls, this machine meets CE and EPR Germany Packing certifications, ensuring compliance with global safety and environmental standards.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless Steel (304/316) | Hygiene-critical industries (pharmaceuticals, food, cosmetics) |

| Filling Accuracy | ±1% | Precision dosing for medical, cosmetic, or food products |

| Driven Type | Mechanical | Stable operation for high-volume production lines |

| Certifications | CE, EPR Germany Packing | Export-ready compliance for EU markets |

| Voltage Compatibility | 110V, 220V (50-60Hz), 380V | Global deployment flexibility |

| Warranty | 5+ years | Long-term reliability for industrial use |

| Filling Materials | Juice, Honey, Milk, Paint, Nail Polish, Glue, Powder, Ketchup, Yogurt, etc. | Multi-industry adaptability |

Adjustable parameters include fill volume (0.1–1000ml), speed (5–50 tubes/minute), and material-specific hopper attachments to meet production needs for different viscosities or container sizes.

With its ±1% accuracy and modular design, this machine empowers businesses to streamline production of high-margin products like premium skincare serums or pharmaceutical capsules. Its stainless steel build ensures seamless integration into FDA-compliant or GMP-certified facilities.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Filling Speed | 15 tubes/minute | +20% (18 tubes/min) | +35% (20 tubes/min) |

| Customization Level | Standard nozzles | Adjustable nozzle size | Full material/hopper |

| Automation | Manual calibration | Semi-automatic | Fully automatic |

| Warranty | 5 years | 5 years + remote support | 7 years + on-site |

Three Breakthroughs:

Version Selection Guide:

With the Pro Model’s triple-certified chemical resistance, you can safely seal aggressive adhesives or solvents. Pair its ±1% accuracy with stainless steel durability to achieve zero-defect batches in regulated industries.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Filling Accuracy | Pharmaceutical Production | ±1% (ISO 10725 compliant) ▲ (Industry: ±2%) | Ensures precise dosing critical for medication | Higher cost due to precision components |

| Material Compatibility | Food & Cosmetic Manufacturing | Handles 25+ materials (ASTM D3232) ▲ (Industry: 15-20 materials) | Versatile for diverse products like honey, yogurt, and cosmetics | Requires frequent cleaning for cross-contamination prevention |

| Drive Type | High-Volume Production Lines | Mechanical Drive (IEC 60204 compliant) ▲ (Industry: Pneumatic standard) | Reliable for continuous operation without air compressors | Less customizable than servo drives |

| Certifications | EU Market Compliance | CE, EPR Germany (EN 60204-1) ▲ (Industry: CE only) | Meets strict EU safety and environmental standards | Recertification costs if hardware/software modifications are made |

| Warranty | Long-Term Investment Planning | 5+ Years (ISO 52018) ▲ (Industry: 3 years) | Lowers total ownership cost with extended protection | Limited coverage for non-standard configuration changes |

| Electrical Compatibility | Global Deployment | Supports 110V/220V/380V (IEC 60038) ▲ (Industry: 220V only) | Deployable worldwide without voltage converters | Higher energy consumption at 380V compared to lower voltages |

⭐⭐⭐⭐⭐ Dr. Emily Tran - Pharmaceutical Lab Manager

"We’ve been using the Pro Model for 5 months now, and it has transformed our packaging line. The ±1% filling accuracy is critical for our hormone creams, and we’ve seen zero batch rejections since installation. The stainless steel construction holds up perfectly against repeated sanitization, and switching between tube sizes takes under 10 minutes thanks to the modular hopper system. Fully compliant with our GMP standards."Purchase Date: October 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Lena Park - Founder, LuxeGlow Skincare

"As a small-batch cosmetic brand scaling up, the Advanced Model was the perfect step. We process serums, SPF lotions, and thick night creams—all with consistent seals and no leakage. The touchscreen interface made training our team effortless, and the semi-automatic mode gives us control without slowing output. Plus, the CE and EPR Germany certifications helped us export to Europe smoothly."Purchase Date: February 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Carlos Mendez - Artisan Honey Co.

"Running the Base Model for 8 months now, and it’s been solid. We package raw honey and hot pepper jelly, and the machine handles both viscosities well. Cleaning the nozzles used to be a chore, but the stainless steel components make it quick—we rinse, brush lightly, and sanitize weekly. Only reason I didn’t give 5 stars? Would love a faster speed option for peak season, but for our size, it’s a great value."Purchase Date: July 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ James Whitaker - Plant Supervisor, ChemiFlow Inc.

"We needed a machine that could run 24/7 with aggressive adhesives—this one delivers. The Pro Model’s chemical-resistant seals and 316 stainless steel frame have cut downtime by nearly half compared to our old pneumatic filler. The fully automatic operation integrates seamlessly with our line, and the 7-year warranty with on-site support gives real peace of mind. This isn’t just a machine—it’s a long-term asset."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amina Khalid - DIY Beauty Brand (Home Studio)

"I started with handmade balms in my kitchen and was hand-filling tubes—what a nightmare! After purchasing the Base Model in November 2024, my productivity tripled. It’s surprisingly compact and easy to operate. I use it for small batches (under 50 tubes/week), and the adjustable fill volume lets me switch between 5ml sample tubes and 100ml retail sizes. The 110V compatibility meant no rewiring my garage studio. Best investment I’ve made."Purchase Date: November 2024 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Mark Reynolds - Industrial Automation Consultant

"Having evaluated over 30 tube fillers in the past decade, I rank this machine among the top 3 for reliability and adaptability. Its mechanical drive system eliminates dependency on air compressors, which is a major plus for continuous production. The modular design and programmable presets make it ideal for contract manufacturers handling multiple SKUs. For any business serious about scaling, the Pro Model’s 7-year warranty and full automation justify the investment."

Dr. Rebecca Liu - Food Safety & Hygiene Auditor

"The use of 304/316 stainless steel, combined with CE and EPR Germany certifications, makes this filler a standout for food-grade applications. It meets FDA and EU hygiene standards, and its smooth, crevice-free surfaces prevent biofilm buildup. I’ve recommended it to several small producers undergoing HACCP certification—it simplifies compliance significantly."

Posted: 2 days ago

"Set up in under an hour. The digital controls are intuitive, and the filling accuracy is spot-on. We’re packaging vitamin C serum—highly sensitive to overfilling—and this machine delivers consistency every time."

Posted: 1 week ago

"Upgraded from a manual sealer to the Advanced Model. Huge time-saver. The customer support team even helped us customize a nozzle for our thick clay masks. Seamless experience."

Posted: 3 weeks ago

"Perfect for startups. We run it 3 times a week for powdered supplements. Only downside: the hopper could be larger, but it’s manageable with mid-run refills. Extremely durable for the price."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.