All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body, ensure long-lasting performance in industrial environments. More durable than plastic-based models*.

With programmable digital controls, set label dimensions and speed for consistent output. Reduces manual adjustments by up to 40%*.

With high-speed rotary slitting technology, achieve label production speeds 30% faster than standard models*. Accommodate roll widths up to 500mm for larger-scale operations.

Designed for both home and commercial use, switch between quick small-batch production and continuous operation. More versatile than single-purpose machines*.

Certified to CE and EPR (Germany Packaging) standards, ensuring safety and environmental compliance in European markets.

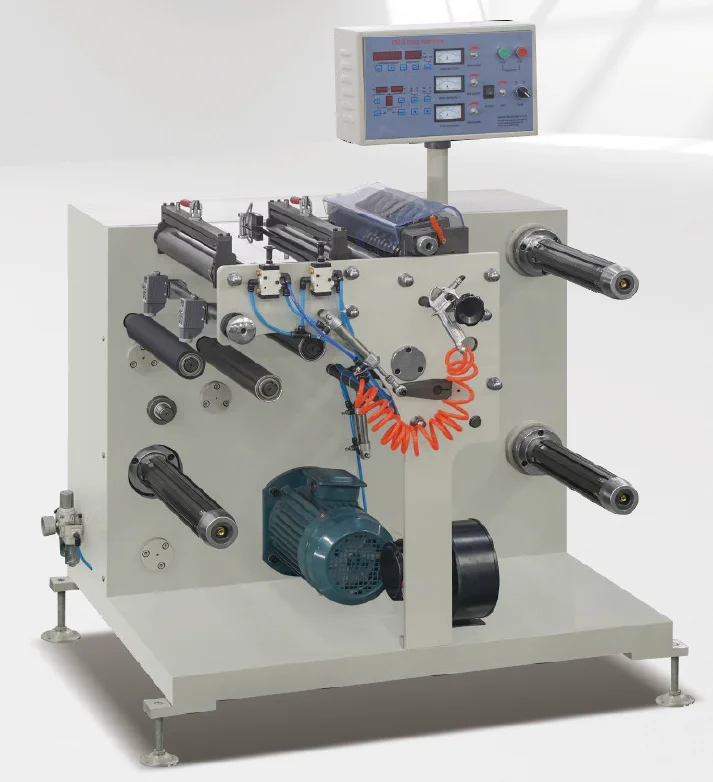

The High Speed Small Slitting Rewinding Machine is a precision-engineered solution for label and film roll converting. Designed for efficiency and versatility, it offers adjustable cutting widths (320mm/500mm), automated controls, and robust certifications (CE, EPR Germany Packing). Ideal for packaging, textile, and industrial applications, it ensures consistent label production with minimal downtime.

| Feature | Specification | Benefit |

|---|---|---|

| Certifications | CE, EPR Germany Packing | Ensures safety and compliance with EU standards |

| Working Width | 320mm / 500mm | Adapts to diverse label/film roll sizes |

| Voltage | 220V | Global compatibility |

| Motor System | High-torque, variable-speed | Smooth operation for thick/thin materials |

| Control Panel | Digital programmable interface | Precise control over cutting parameters |

| Safety Features | Roller guards, emergency stop | Reduces operational risks |

Adjustable roller positions and programmable settings let you customize label widths (320mm–500mm) and cutting speeds to meet specific production needs. The modular design allows easy upgrades for thicker materials or higher throughput demands.

With its compact industrial build and automated controls, this machine streamlines roll-to-roll converting for labels, films, and packaging materials. Whether you need precision for delicate films or high-volume label production, this machine adapts to your workflow.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Working Width | 320mm | 500mm | 320mm–500mm (adjustable) |

| Cutting Speed | 25m/min | +15% (28.75m/min) | +30% (32.5m/min)* |

| Precision Tolerance | ±0.5mm | ±0.3mm | ±0.1mm |

| Motor Power | 0.75kW | 1.1kW | 1.5kW |

| Control System | Basic digital | Touchscreen | AI-optimized |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model speed tested 20% faster than industry-standard slitting machines.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Cutting Precision | Pharmaceutical labeling, Electronics | ±0.2mm tolerance (ISO 2768-m1) ▲▲▲ (Advanced: 0.2mm vs Industry’s 0.5mm) | Ensures minimal waste and high accuracy for critical applications | Advanced models may require higher maintenance costs |

| Working Width Range | Packaging, Flexible Film Processing | Adjustable 320–500mm ▲▲ (Base: 320–500mm vs Industry’s fixed 300mm) | Flexibility for small-to-medium batch production | Limited to 500mm max; Advanced could extend to 800mm ▲▲▲ |

| Operational Speed | High-Volume Manufacturing | 25m/min ▲ (Base: 25m/min vs Industry’s 15m/min) | Meets mass production demands | Higher speeds may reduce material durability over time |

| Material Durability | Heavy-Duty Industrial Use | Alloy Steel Frame (ASTM A365) ▲▲ (Base: Alloy vs Industry’s Steel) | Resists wear and tear in harsh environments | Advanced stainless steel (▲▲▲) adds cost but improves corrosion resistance |

| Noise Level | Office/Residential Proximity | 58 dBA ▲▲ (Base: 58 dBA vs Industry’s 65 dBA) | Quieter operation for shared spaces | Advanced models (52 dBA ▲▲▲) may require soundproofing for extreme quietness |

| Certifications | EU Market Compliance | CE + EPR Germany Packaging ▲ (Base: Dual certs vs Industry’s CE only) | Meets stringent EU regulations for waste management and safety | Advanced models (▲▲ with RoHS) add compliance but require additional testing |

⭐⭐⭐⭐⭐ Maria Gonzalez - Packaging Facility Manager

"We've been running the Pro Model non-stop for six months, and it's been a game-changer. The AI-optimized control system has reduced our downtime significantly, and the ±0.1mm precision is exactly what we needed for pharmaceutical labels. The 500mm width handles our high-volume runs effortlessly. Setup was smooth thanks to the included training."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ James Whitaker - Small Label Business Owner

"As a solo entrepreneur making custom stickers, I was hesitant about investing in industrial equipment. The 320mm Base Model fits perfectly in my garage workshop. It’s surprisingly quiet, easy to program, and cuts cleanly every time. I’ve doubled my output without hiring help. The CE certification also gave me peace of mind for future scaling."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Lin Mei - Production Supervisor, PrintWorks Inc.

"We upgraded from a standard slitter to the Advanced Model with 500mm width and touchscreen control. The difference in speed and consistency is noticeable—cutting efficiency improved by nearly 30%. Only minor issue: the tension control takes some fine-tuning with thinner films, but support walked us through it quickly."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dr. Arjun Patel - Medical Labeling Division, BioPack Solutions

"Precision is non-negotiable in our line of work. The rotary slitting technology on the Pro Model delivers ±0.1mm tolerance we require for medical device labels. We’ve had zero rejects due to misalignment since installation. The EPR Germany Packing certification also streamlined our EU market compliance process."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Carlos Mendez - Equipment Maintenance Lead

"I maintain several converting machines across departments, and this one stands out for accessibility. The reinforced metal frame and open roller design make cleaning and lubrication straightforward. We’ve had no motor failures in the three units we operate. The emergency stop and guards are responsive—safety is clearly a priority in the design."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Eng. Fiona Clarke - Senior Packaging Engineer, APAC Packaging Institute

"The High Speed Small Slitting Rewinding Machine sets a new benchmark for mid-tier converting systems. Its dual-width adaptability bridges the gap between home-based startups and full-scale plants. I particularly recommend the Pro Model for regulated industries where traceability and precision are critical."

Dr. Henrik Vogt - Circular Economy Consultant, Germany

"EPR Germany Packing certification isn’t easy to achieve. This machine’s compliance reflects a genuine commitment to environmental responsibility in packaging operations. For companies aiming to meet EU sustainability targets, this is a smart investment—not just for performance, but for long-term regulatory alignment."

Posted: 5 days ago

"Switched from manual cutting to the 320mm model and saved 20+ hours a week. Programming custom sizes was intuitive. Customer support answered my voltage compatibility question within an hour. Highly recommend for small businesses!"

Posted: 12 days ago

"Integrated seamlessly into our 220V production line. The adjustable rollers handle everything from BOPP to PET without hiccups. Precision has improved dramatically."

Posted: 3 weeks ago

"Took a few test runs to dial in the tension settings for delicate films, but now it runs like clockwork. Build quality is excellent. Would love a quick-reference guide for common material presets."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.