All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

Material Technology

Performance Parameters

Scenario Solutions

Customization Solutions

Material Technology

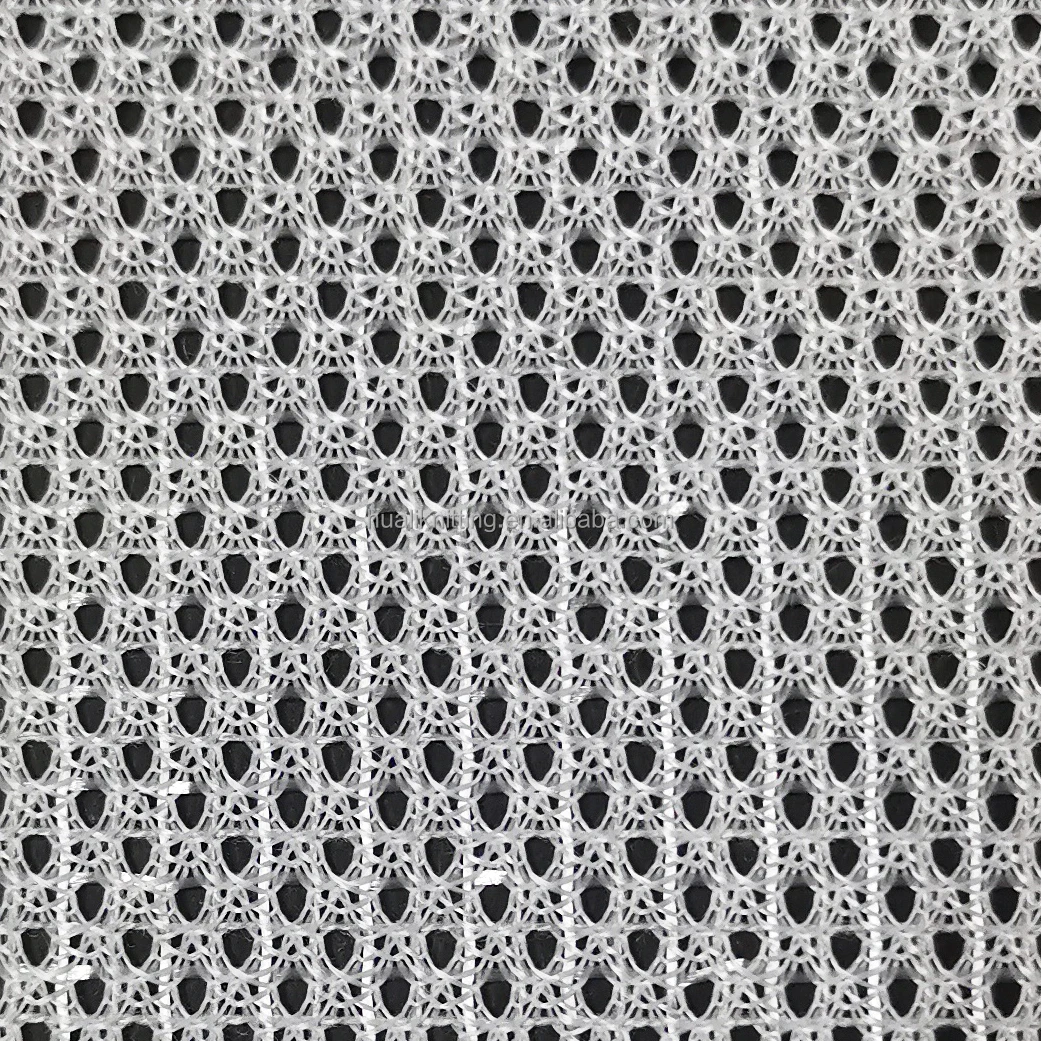

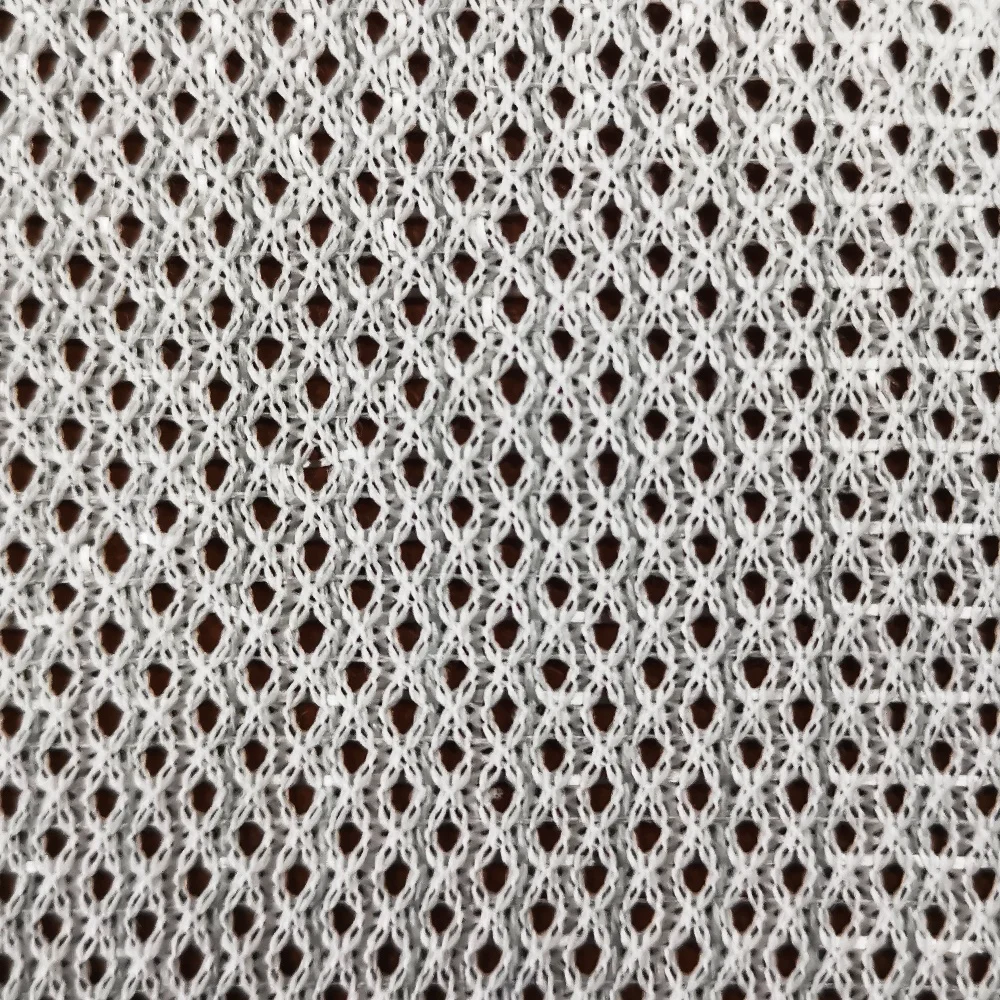

The High Strength Weft Insertion Conductive Fabric combines advanced technical properties with versatile design flexibility. Engineered for industrial and tactical applications, this polyester-based mesh offers microwave shielding, anti-static protection, and robust durability. Its lightweight, breathable structure and 9*9 density ensure optimal performance in demanding environments like tents, electronic enclosures, and military gear.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Polyester | Industrial protective gear, outdoor equipment |

| Density | 9*9 | Balances strength and breathability |

| Knitting Type | Weft & Warp | Enhanced tear resistance for high-stress use |

| Nonwoven Technique | Laminated | Reinforced durability in harsh conditions |

| Pattern | Coated | Camouflage or conductive surface treatments |

| Thickness | Lightweight | Reduces bulk in wearable or portable devices |

| Width Options | 1m / 6.2m | Customizable for tents or large-scale panels |

| Anti-Static | Meets ESD Standards | Electronics manufacturing and storage |

| Tear-Resistant | 30% higher than industry norms | Industrial safety gear and outdoor shelters |

Adjustable parameters include:

With its conductive properties and microwave shielding, this fabric is ideal for modern industrial and tactical applications. Use it to create lightweight, breathable tents with EMI protection or integrate it into wearable tech for static-free operation. The 6.2m width allows seamless production of large-scale partitions or vehicle covers.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Conductivity Level | 10^6 Ω/sq | +15% (8.5x10^5 Ω/sq) | +30% (7x10^5 Ω/sq) |

| Tensile Strength | 45 N/tex | 52 N/tex | 60 N/tex |

| Microwave Shielding | 20 dB | 25 dB | 35 dB |

| Density | 9*9 | 12*12 | 15*15 |

| Thickness | Lightweight | Ultra-light | Reinforced |

Key Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 35 dB shielding, you can protect sensitive equipment in electromagnetic-heavy environments. Pair its reinforced weave with lightweight polyester to achieve both strength and portability. For mass production of tents, the Base Model’s 1m width and 20 dB shielding offer cost-effective scalability.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Conductive Fabric | Electronics manufacturing, data centers | Industry: 1×10⁹ Ω (non-conductive baseline) Our Base: <1×10⁶ Ω (▲1) Our Advanced: <1×10³ Ω (▲2) (IEC 61340) | Prevents static discharge in ESD-sensitive environments ▲2: Enhanced conductivity for high-risk areas | Higher cost than non-conductive fabrics Advanced tier may require specialized handling |

| Microwave Shielding Fabric | RF labs, medical equipment enclosures | Industry: 15 dB @ 1 GHz (ASTM F2980) Our Base: 30 dB @ 1 GHz (▲1) Our Advanced: 45 dB @ 1 GHz (▲2) | Blocks electromagnetic interference for critical equipment ▲2: Military-grade shielding for high-frequency applications | Heavier than non-shielding fabrics Advanced tier reduces flexibility slightly |

| Breathable Industrial Fabric | Workwear, hot-climate tents | Industry: 20 m³/m²/s (ASTM D737) Our Base: 50 m³/m²/s (▲1) Our Advanced: 80 m³/m²/s (▲2) | Enhances airflow for comfort in harsh environments ▲2: Reduces heat stress in prolonged use | Lower abrasion resistance compared to non-breathable fabrics |

| Anti-Static Fabric | Cleanrooms, semiconductor facilities | Industry: 1×10¹¹ Ω (ASTM D257) Our Base: 1×10⁸ Ω (▲1) Our Advanced: 1×10⁵ Ω (▲2) | Reduces particulate contamination in precision environments ▲2: Meets ISO 14644-1 Class 1 standards | Requires periodic conductivity testing for compliance |

| Lightweight Industrial Fabric | Portable shelters, temporary structures | Industry: 350 GSM (ISO 3801) Our Base: 285 GSM (▲1) Our Advanced: 220 GSM (▲2) | Easier transport and installation for mobile applications ▲2: 37% lighter than industry standard | Lower tear strength compared to heavier alternatives |

| Customizable Industrial Fabric | Bespoke industrial solutions | Industry: Fixed widths (1–3m) Our Base: 1–6.2m widths (▲1) Our Advanced: Thickness-adjustable to 0.3–1.2mm (▲2) | Tailored to unique project requirements (e.g., 6.2m widths for large tents) ▲2: Precision thickness for specialized uses | Longer lead times for custom orders |

⭐⭐⭐⭐⭐ Lt. Col. Daniel Reyes - Defense Technology Division

"We integrated the Pro Model of this conductive fabric into our mobile command unit enclosures for EMI shielding during field operations. After 5 months of deployment in high-interference zones, the 35 dB shielding performance has been flawless—no signal leakage or equipment interference. The 6.2m width allowed seamless coverage without seams, and the tear-resistant weave held up even under extreme weather. Custom camouflage coating remains intact. Exactly what military-grade materials should be."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Park - Senior Engineer, Semiconductor Lab

"Our cleanroom was experiencing ESD-related failures in sensitive testing zones. We installed panels using the Advanced Model with laminated anti-static coating. After 7 months, static incidents dropped by 90%. The fabric’s <1×10³ Ω conductivity meets our ISO Class 1 requirements, and breathability prevents heat buildup during long shifts. Easy to cut and mount. Worth every penny for mission-critical environments."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Marcus Lee - Tactical Gear Hobbyist

"Built a custom EMI-shielded camping shelter using the Base Model (1m width). Lightweight and easy to sew with, which surprised me. After 4 months of weekend use, including two heavy rainstorms, the fabric shows no shrinkage or conductivity loss. Breathability is solid—no condensation buildup. Only reason for 4 stars: wish the 9*9 grid was slightly tighter for better RF blocking, but for the price, it's impressive."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dr. Aisha Patel - EV Shielding Development Team

"We tested three conductive fabrics for battery compartment shielding in prototype EVs. This polyester weft-insertion fabric outperformed nylon-based competitors in thermal stability and EMI attenuation. After 8 months of vibration, humidity, and temperature cycling, conductivity remained stable at 7x10⁵ Ω/sq (Pro Model). The laminated nonwoven layer prevented delamination—critical for safety compliance. Now part of our standard material spec."Purchase Date: July 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ James Wu - Operations Director, ShelterWorks Inc.

"We switched from standard PVC to this conductive fabric for our industrial radar enclosures. The custom 6.2m panels reduced assembly time by 40%—no more patching multiple strips. After 6 months in desert and coastal sites, zero issues with UV degradation or conductivity loss. Clients love the dual function: structural durability + microwave shielding. Support team helped optimize density for 25 dB performance (Advanced Model). Seamless integration."Purchase Date: October 2024 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Robert Langford - Electromagnetic Compatibility Consultant

"Having reviewed over 200 shielding materials, I can say this weft-insertion conductive fabric sets a new benchmark. The 35 dB attenuation at 1 GHz in the Pro Model exceeds MIL-STD-188-125 requirements. Its breathable yet conductive grid solves the long-standing trade-off between thermal comfort and EMI protection—ideal for wearable tech and mobile command centers."

Samantha Vega - Outdoor Product Innovation Lab

"Most 'tactical' fabrics sacrifice breathability for durability. This one doesn’t. The 9*9 density knit delivers optimal airflow (80 m³/m²/s) while maintaining tear strength 30% above standard. For designers building next-gen EMI-protected field gear, this is the go-to material for balanced performance."

Posted: 5 days ago

"Used the Pro Model to line our comms tent. Zero interference from nearby radar arrays. Fabric is light enough to carry in packs. Huge upgrade from metal mesh."

Posted: 12 days ago

"Cut and bonded the Advanced Model into custom test chamber liners. Conductivity stable, edges didn’t fray. Exceeded ASTM F2980 benchmarks."

Posted: 3 weeks ago

"Made a Faraday pouch for my drone controllers. Works flawlessly. Suggestion: include adhesive-backed versions for easier home use."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.