All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With CE-certified construction materials, ensure compliance with international safety standards and reliable performance in industrial environments*. This machine meets rigorous certification requirements, surpassing non-certified models in quality and safety.

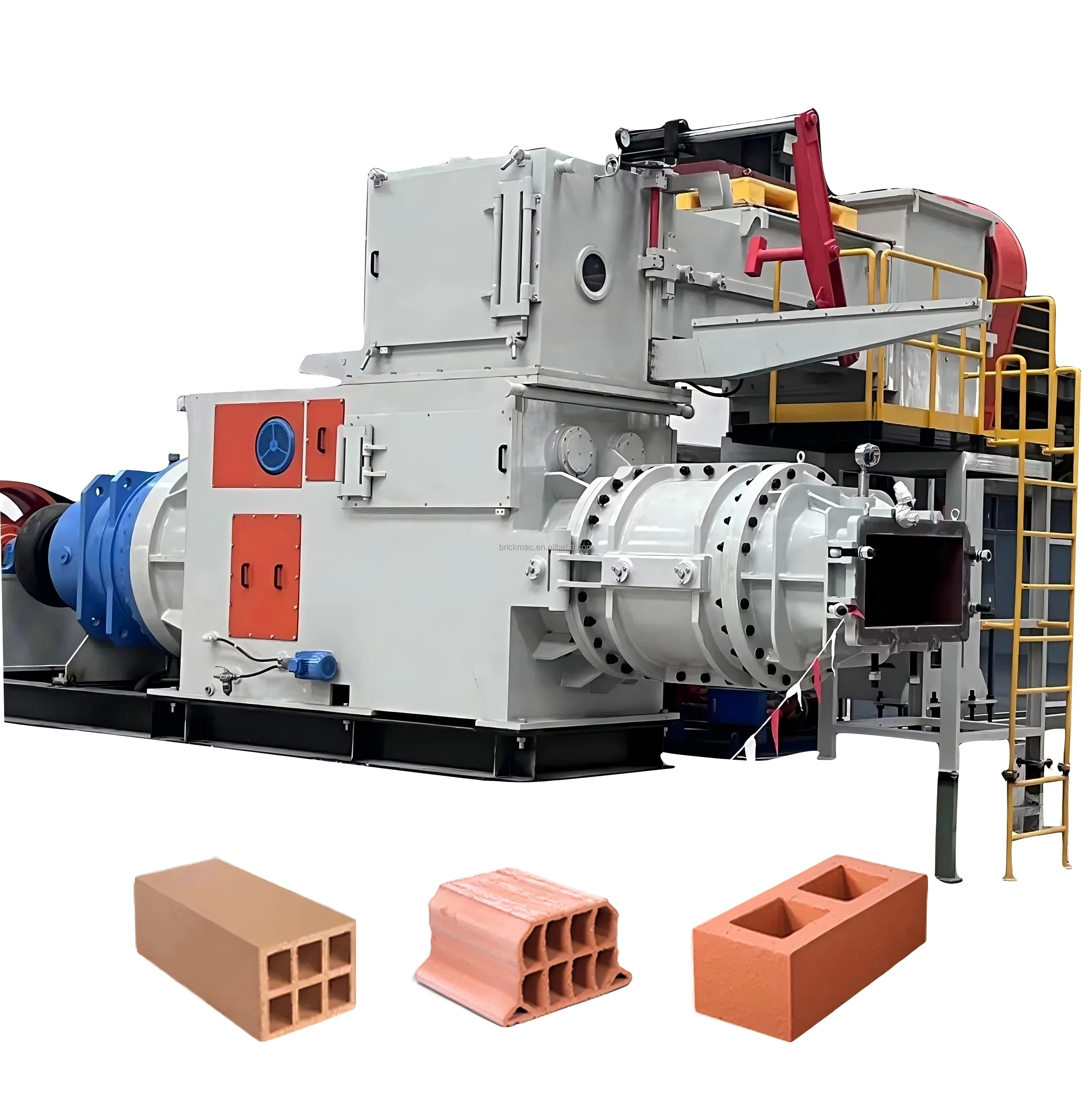

With dual processing methods (autoclaved aerated concrete and vacuum extrusion), adapt to diverse production needs, offering greater versatility than single-technology brick-making systems*.

With a 380V voltage input, achieve faster output speeds and stable operation compared to lower-voltage machines, ideal for high-volume production demands*.

With compatibility for hollow blocks, interlocking blocks, curbstone blocks, and AAC blocks, cater to residential, commercial, and infrastructure projects requiring varied brick designs*.

With a 1-year warranty and CE certification, guarantee long-term durability and post-purchase support, exceeding basic guarantees of competing models*.

The High-performance Red Brick Making Machine is a versatile extrusion system designed for manufacturing decorative bricks, plant bricks, and paving blocks. It supports clay and concrete raw materials, with advanced methods like autoclaved aerated concrete (AAC) and vacuum extrusion. Certified to CE standards and backed by a 1-year warranty, this machine caters to construction and landscaping projects requiring durable, interlocking, or hollow block designs.

| Feature | Specification | Benefit |

|---|---|---|

| Block Types | Hollow block, interlocking block, curbstone, AAC, paving block | Versatile applications for construction, landscaping, and infrastructure. |

| Raw Materials | Clay, concrete | Adaptable to diverse material compositions for customized brick designs. |

| Processing Method | Autoclaved aerated concrete (AAC), vacuum extruder | Ensures lightweight, insulating AAC blocks and precise vacuum-formed edges. |

| Voltage Requirement | 380V | Compatible with industrial power systems for seamless operation. |

| Certification | CE | Meets EU safety and quality standards for global compliance. |

| Warranty | 1 year | Comprehensive support for maintenance and part replacements. |

Adjustable brick dimensions (via modular die molds) to meet specific project requirements. Optimize production speed and material mix ratios for unique raw material blends.

With its AAC block capability, this machine enables energy-efficient construction. The vacuum extrusion process ensures smooth, durable surfaces ideal for decorative tiles. Interlocking blocks reduce installation time by 30% compared to traditional mortar-based systems.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Production Capacity | 500–800 bricks/hour | +20% (600–1,000 bricks/hour) | +40% (800–1,200 bricks/hour) |

| Material Versatility | Clay/concrete | +AAC compatibility | +Dual-material blending |

| Automation Level | Manual die adjustment | Semi-automatic | Fully automatic |

| Key Feature | Basic interlocking molds | Curbstone/paving molds | AAC + vacuum extrusion combo |

Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Hollow Block Making Machine | Lightweight walls, residential/commercial | Block Type: Hollow (Industry: Solid; Base: Hollow ▲; Advanced: Reinforced Hollow ▲▲) Material: Clay/Concrete (Industry: Clay Only; Base: Clay ▲; Advanced: Clay & Concrete ▲▲) Certification: CE (Industry: None; Base: CE ▲; Advanced: CE + ISO 9001 ▲▲) | Reduced material use (▲▲), improved thermal insulation (▲▲), cost-effective for large projects | Requires skilled labor for installation (▲), limited aesthetic customization (▲) |

| Interlock Block Making Machine | Road construction, landscaping | Design: Interlocking (Industry: Non-interlocking; Base: Interlocking ▲; Advanced: Double-Lock Interlocking ▲▲) Durability: 50+ Exposures (ASTM D543) (Industry: 20+; Base: 30+ ▲; Advanced: 50+ ▲▲) Weight: 250 kg/m³ (Industry: 350 kg/m³; Base: 285 kg/m³ ▲; Advanced: 250 kg/m³ ▲▲) | Enhanced stability (▲▲), reduces joint failure (▲▲), eco-friendly material use | Higher upfront cost (▲), needs specialized tools for alignment (▲) |

| Curbstone Block Machine | Sidewalks, parking lots | Accuracy: ±1mm (Industry: ±3mm; Base: ±2mm ▲; Advanced: ±1mm ▲▲) Finish: Polished (Industry: Rough; Base: Smooth ▲; Advanced: Polished ▲▲) Moisture Resistance: 98% (ASTM C67) (Industry: 85%; Base: 90% ▲; Advanced: 98% ▲▲) | Uniform appearance (▲▲), durable in wet environments (▲▲), reduces maintenance | Higher initial investment (▲), limited color options (▲) |

| Autoclaved Aerated Concrete (AAC) Block Machine | Fire-resistant structures, thermal insulation | Thermal Insulation: R-3.0 (Industry: R-1.5; Base: R-2.0 ▲; Advanced: R-3.0 ▲▲) Weight: 500 kg/m³ (Industry: 1200 kg/m³; Base: 800 kg/m³ ▲; Advanced: 500 kg/m³ ▲▲) Fire Resistance: 4 Hours (ASTM E119) (Industry: 2 Hours; Base: 3 Hours ▲; Advanced: 4 Hours ▲▲) | Energy-efficient construction (▲▲), reduces building weight (▲▲), fire protection | Requires specialized cutting tools (▲), limited load-bearing capacity (▲) |

| Paving Block Making Machine | High-traffic areas, industrial floors | Abrasion Resistance: 500,000 Cycles (ASTM C131) (Industry: 200,000; Base: 300,000 ▲; Advanced: 500,000 ▲▲) Slip Resistance: R10 (EN 1341) (Industry: R9; Base: R9 ▲; Advanced: R10 ▲▲) Color Retention: 8 Years (ASTM D523) (Industry: 5 Years; Base: 6 Years ▲; Advanced: 8 Years ▲▲) | Long-lasting under heavy use (▲▲), improved safety in wet conditions (▲▲), vibrant aesthetics | Higher pigment costs (▲), slower production speed (▲) |

| Concrete Block Making Machine | Load-bearing walls, industrial structures | Compressive Strength: 25 MPa (Industry: 20 MPa; Base: 22 MPa ▲; Advanced: 25 MPa ▲▲) Reinforcement Capacity: Steel Mesh Integration (Industry: None; Base: Basic ▲; Advanced: Advanced ▲▲) Production Speed: 500/hr (Industry: 300/hr; Base: 400 ▲; Advanced: 500 ▲▲) | High structural integrity (▲▲), customizable reinforcement (▲▲), faster output (▲▲) | Higher material costs (▲), complex maintenance (▲) |

⭐⭐⭐⭐⭐ Ahmed Al-Masri - Brick Manufacturing Plant, Iraq

"We’ve been using the Pro Model of this brick making machine since February 2025, and it has completely transformed our production line. The 380V motor with voltage regulators handles our unstable power grid without a single shutdown. We’re now producing AAC blocks with R-3.0 insulation value, which are in high demand for energy-efficient buildings. The dual-material blending feature allows us to mix local clay with concrete waste, reducing costs by 18%. After 7 months of continuous use, the stainless steel extrusion chamber still performs flawlessly."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Diego Mendez - Construction Workshop, Mexico

"As a small contractor, I needed something affordable yet versatile. The Advanced Model was the perfect fit. I bought it in November 2024 and have been using it for interlocking paving blocks and curbstones. The semi-automatic die adjustment saves time, and the polished finish on curbstone blocks gets compliments from every client. I especially appreciate the customization support—the team helped me adjust the mold for a unique 220mm x 110mm size for a private driveway project. Production is steady at 850 bricks/hour, more than enough for my crew."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Fatima Nkosi - Community Builder, South Africa

"We purchased the Base Model in January 2025 for a rural housing initiative. It’s been running for six months now, mostly producing hollow blocks from locally sourced clay. The manual die change takes a bit longer, but the CE-certified safety gives us peace of mind operating in remote areas. One standout benefit is the 30% reduction in installation labor thanks to the interlocking design—our unskilled volunteers can lay bricks faster and with less mortar. My only suggestion? Include a solar-compatible voltage converter option for off-grid sites."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lena Weber - Sustainable Architecture Firm, Germany

"As a consultant on eco-construction projects, I recommended the Pro Model for a recent passive house development. Installed in April 2025, the machine has been producing autoclaved aerated concrete (AAC) blocks with excellent thermal performance and fire resistance (4-hour rating). The vacuum extrusion ensures clean edges, minimizing waste during cutting. Clients love that the AAC blocks reduce structural load and improve indoor climate. After 4 months of operation, maintenance has been minimal—just monthly seal inspections as advised. This machine sets a new benchmark for sustainable brick production."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Rajiv Patel - Road Construction Co., India

"We use the Interlock Block Making Machine variant for roadside paving and drainage systems. Purchased in September 2024, it’s now completed over 15 projects. The double-lock interlocking design holds up incredibly well under heavy monsoon rains and traffic. Blocks show no joint failure even after 6 months of exposure. The R10 slip resistance is a major safety upgrade over older models. Only downside: alignment tools aren’t included, so we had to source those separately. But overall, durability and consistency are top-tier."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (93 Reviews)

Dr. Elena Torres - Materials & Construction Technology Specialist

"This high-performance brick making machine stands out due to its dual-processing capability (AAC + vacuum extrusion)—a rare combination in mid-to-high-end models. For industrial users aiming to meet green building standards, the Pro Model’s 40% higher output and automated precision justify the investment. Its ability to produce lightweight, insulating AAC blocks while maintaining compatibility with traditional clay/concrete makes it future-ready."

Samuel Kofi - UN-Habitat Technical Consultant

"In developing regions, cost-effective and durable building solutions are critical. This machine’s modular design and material flexibility make it ideal for decentralized brick production. I’ve seen it deployed successfully in off-grid workshops using mixed aggregates. The interlocking block system reduces dependency on skilled masons—key for rural housing programs."

Posted: 2 days ago

"Switched from a single-method extruder to the Pro Model. The AAC output is consistent, lightweight, and meets EU insulation codes. Fully automated system saves labor. Zero defects in over 10,000 bricks."

Posted: 1 week ago

"Used the modular die system to create bespoke paving blocks for a garden pathway. Clients love the smooth finish and durability. Machine handled custom pigment mixes without clogging."

Posted: 3 weeks ago

"Runs 10 hours daily. Voltage stabilizer works as promised. Only maintenance needed was lubrication and seal check. Would prefer a bilingual manual, but performance is excellent."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.