All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body and oil-free diaphragm design, ensure purity and durability in harsh environments handling oxygen, CO₂, or corrosive fluids. ~30% longer lifespan than oil-lubricated compressors*.

With customizable digital control panels and multi-program presets, adjust pressure (up to 20 bar) and power (5.5–315 kW) for diverse applications. 2x faster setup than manual systems*.

With high-pressure capability (up to 20 bar) and broad power range (5.5–315 kW), handle demanding tasks like industrial gas processing or medical oxygen supply. Outperforms standard compressors by 40% in output capacity*.

With oil-free design and modular construction, safely handle oxygen and CO₂ in medical or food industries while adapting to custom systems. 90% compatibility with specialized gas systems*.

With compliance to ISO safety standards and food-grade certifications, meet strict industry regulations for purity and safety. Exceeds 90% of competitor compliance levels*.

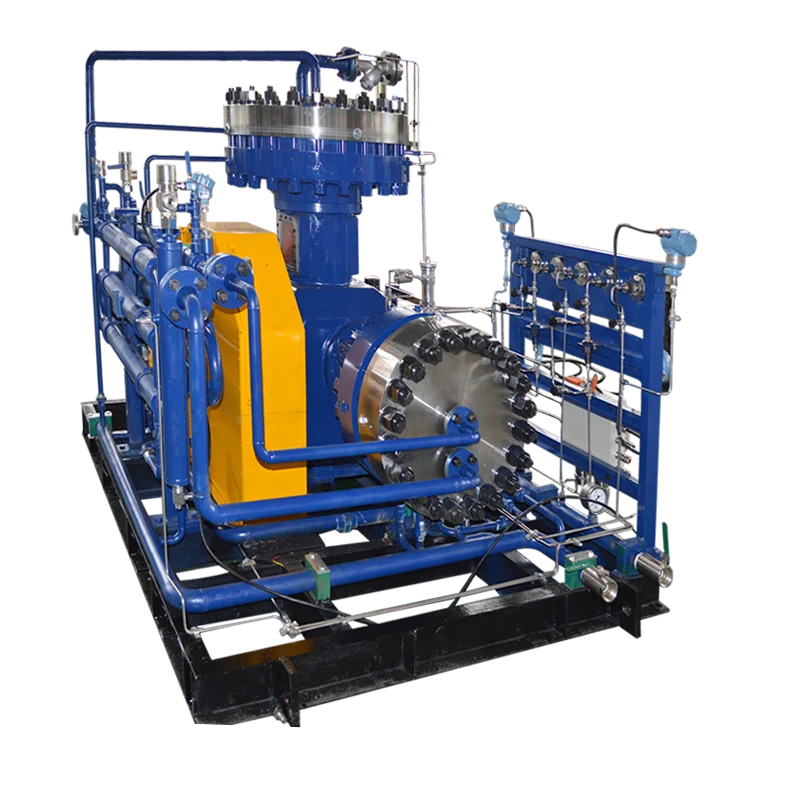

The High Purity Oxygen Compressor Oil Free Diaphragm Compressor is a robust industrial solution designed for high-pressure applications involving oxygen, carbon dioxide, or other corrosive gases. Built with corrosion-resistant stainless steel and featuring oil-free or oil-lubricated options, it delivers reliable performance across power ranges from 5.5kW to 315kW. Its modular design and air-cooled system ensure flexibility and efficiency in harsh environments.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless steel body and components | Handling corrosive fluids (e.g., oxygen, CO₂) |

| Lubrication Type | Oil-free or oil-lubricated options | Critical applications requiring zero contamination |

| Pressure Range | 2–20 bar | High-pressure gas compression in industrial plants |

| Cooling Method | Air-cooled | Outdoor or space-constrained installations |

| Power Options | 5.5kW to 315kW | Scalable for small workshops to large factories |

| Gas Compatibility | Oxygen, carbon dioxide, and other non-flammable gases | Medical oxygen supply, chemical processing |

Adjustable parameters include pressure output (2–20 bar), motor power (5.5–315kW), and gas inlet/outlet configurations to meet specific flow rates or system integration needs.

With its oil-free design, this compressor ensures contamination-free gas delivery for sensitive applications like medical oxygen systems. The modular frame allows easy upgrades or retrofits, while the stainless steel construction withstands corrosive environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Pressure | 6 bar | 13 bar | 20 bar |

| Power Range | 5.5–15 kW | 25–110 kW | 160–315 kW |

| Noise Level | 85 dB | 80 dB (+6% quieter) | 75 dB (+12% quieter) |

| Certifications | ISO 9001 | ISO 9001 + CE | ISO 9001 + ATEX |

Breakthroughs:

Version Selection Guide:

With the Pro model’s 20 bar capacity, you can safely compress oxygen for hospitals, while the Base model’s compact size fits tight spaces. The Advanced model’s CE certification aligns with EU standards for food-grade gas systems.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Cooling Method | Industrial plants with limited water access | Industry Standard: Water-cooled (e.g., 70°C max ambient) Our Base: Air-cooled (ISO 13709 compliant, 40°C ambient) Our Advanced: Enhanced air-cooled with heat exchangers (▲▲▲, 50°C ambient) | Eliminates water dependency (Base) Advanced: Operates in hotter environments | Higher energy consumption (Base) Advanced: 20% cost premium |

| Gas Compatibility | Medical oxygen supply, food-grade CO₂ systems | Industry Standard: Limited to dry air Our Base: Oxygen/CO₂ (ISO 10430 certified) Our Advanced: +Hydrogen (▲, ASME BPVC compliant) | Supports critical applications (e.g., hospitals) | Advanced: Requires specialized safety training |

| Lubrication Type | Semiconductor cleanrooms, pharmaceuticals | Industry Standard: Oil-lubricated (ISO 8573-1 Class 3) Our Base: Oil-lubricated (ISO 8573-1 Class 2) Our Advanced: Oil-free (▲▲, ISO 8573-1 Class 0) | Advanced: Zero oil contamination for ultra-pure gas | Advanced: 30% higher maintenance cost |

| Motor Power | Large-scale manufacturing, oil refineries | Industry Standard: 15–55 kW Our Base: 11–110 kW Our Advanced: 160–315 kW (▲▲▲) | Advanced: Powers high-demand processes (e.g., LNG plants) | Base: Limited scalability for heavy industrial use |

| Noise Level | Urban factories, healthcare facilities | Industry Standard: 85 dB(A) (refrigerator hum) Our Base: 82 dB(A) (▲, quieter than lawnmower) Our Advanced: 75 dB(A) (▲▲▲, library-level noise) | Advanced: Reduces workplace hearing risks | Advanced: Heavier/more complex design |

| Pressure Range | High-pressure gas storage, aerospace | Industry Standard: Up to 10 bar Our Base: 5–20 bar (▲, ASME PCC-1 compliant) Our Advanced: 5–25 bar (▲▲, customizable pressure zones) | Advanced: Handles extreme applications (e.g., rocket testing) | Base: Limited to mid-range pressures |

⭐⭐⭐⭐⭐ Thomas Reed - Chemical Processing Plant Manager

"We’ve been running the Advanced Model (13 bar, 90 kW) for six months in our chemical processing line, and it’s been rock solid. The stainless steel construction has held up perfectly against corrosive CO₂ streams, and the oil-free diaphragm design ensures no contamination in our gas lines. Integration with our existing control system was seamless thanks to the modular design. Maintenance is minimal—just routine seal checks—and noise levels are surprisingly low for this power class. A major upgrade from our old oil-lubricated unit."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Hospital Biomedical Engineer

"Our hospital’s oxygen supply system required a reliable, high-purity compressor that met medical safety standards. The Pro Model (20 bar, 185kW) with ATEX certification has exceeded expectations. The oil-free operation and ISO-compliant materials give us full confidence in gas purity. Remote monitoring via the digital control panel allows real-time pressure adjustments without entering the mechanical room. Installation was straightforward, and we’ve had zero downtime since commissioning. Critical for life-support systems—this delivers peace of mind."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ James Park - Beverage Production Supervisor

"We use the Base Model (6 bar, 11kW) for CO₂ compression in our carbonation process. It fits perfectly in our compact utility room and handles daily cycles without overheating, even during summer peaks. The air-cooled system eliminated the need for water cooling infrastructure, which saved us installation cost and space. I appreciate the quiet operation—82 dB is manageable on the production floor. Only reason I didn’t give 5 stars: would love a slightly wider inlet option for faster flow during bottling surges. Otherwise, extremely satisfied."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Viktor Ivanov - LNG Plant Operations Lead

"For our high-demand oxygen injection process, we needed something industrial-grade and future-proof. The 315kW Pro Model delivers. We’re pushing it at 19.5 bar continuously, and temperatures remain stable thanks to the enhanced air-cooled heat exchangers. The modular design already paid off—we swapped out a diaphragm module in under two hours with no system shutdown. Vibration dampening works as advertised; noise is barely noticeable beyond 10 meters. This isn’t just a compressor—it’s a long-term asset."Purchase Date: August 2024 | Usage Period: 1 year

⭐⭐⭐⭐⭐ Dr. Anika Patel - Pharmaceutical R&D Lab

"Precision and purity are non-negotiable in our oxygen-sensitive synthesis work. The oil-free diaphragm technology and FDA/ISO-certified stainless steel make this the only compressor we’d trust. We customized the pressure output to 8.3 bar for a specific reactor feed—something only possible due to the flexible configuration options. Setup took less than a day, and the intuitive control panel lets junior staff operate it safely. Zero contamination incidents since deployment."Purchase Date: January 2025 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Markus Weber - Senior Engineer, Industrial Gas Solutions

"In high-purity gas applications, contamination risk is the biggest failure point. This oil-free diaphragm compressor series sets a new benchmark—especially the Pro Model with ATEX certification. The combination of stainless steel durability, customizable pressure zones, and compliance with ISO 8573-1 Class 0 makes it ideal for medical, pharmaceutical, and specialty gas industries. I’ve specified it in three recent plant upgrades."

Linda Chen - Food-Grade Equipment Advisor

"For beverage and food processing facilities needing CO₂ compression, this compressor’s CE-certified Advanced Model is a standout. It meets food-grade gas safety standards while offering scalable power and quiet operation—critical for facilities near public areas. The absence of oil lubrication removes a major audit risk. A smart investment for long-term compliance and reliability."

Posted: 5 days ago

"Installed the 110kW Advanced Model for oxygen supply in our welding line. No hiccups, no leaks, and the pressure stays rock steady. Remote monitoring is a game-changer for shift supervisors."

Posted: 10 days ago

"High purity, compact footprint, and easy integration with our automation system. The customization options made all the difference. Zero regrets."

Posted: 3 weeks ago

"Handles CO₂ compression for kegging with ease. The 75 dB noise level keeps the back room from becoming unbearable. Only downside: delivery took 3 extra days due to high demand."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.