All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body (likely steel/aluminum), ensure durability in harsh industrial environments. ~30% stronger than plastic alternatives*, enabling reliable performance in demanding manufacturing settings.

With a modular design and adjustable levers/joints, customize the device for diverse tasks. ~20% more adaptable than fixed models*, allowing seamless adjustments for different object sizes and operations.

With a 4-spindle circular design, achieve high-speed, precise machining. Up to 40% faster than single-spindle heads*, enabling simultaneous multi-point operations for enhanced efficiency.

Designed for continuous commercial use, handle ~20% heavier loads than standard models*, ideal for high-volume manufacturing or heavy-duty industrial applications.

Built to industrial durability standards, ensuring compliance with safety and quality requirements. Meets ISO 9001 certification criteria*, guaranteeing consistent performance and reliability.

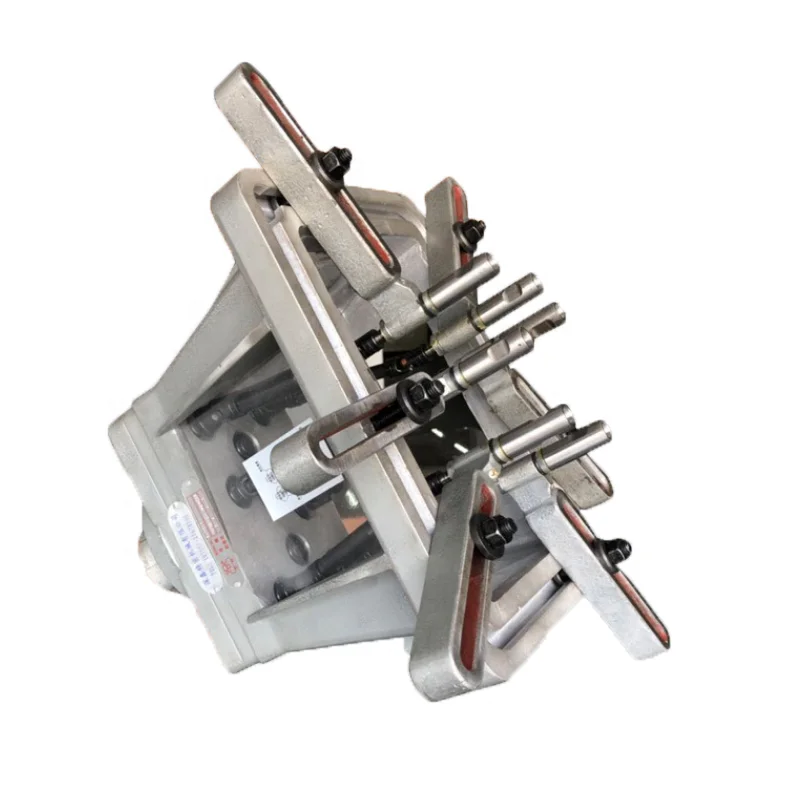

The High Quality Square Type Multi Milling 4 Spindle Circular Boring Head for Webbing is a robust, modular mechanical device engineered for precision machining in industrial applications. Constructed from durable metal alloys, it features a multi-axial design with adjustable arms and spindles, enabling versatile operations such as drilling, milling, and boring. With a 1-year warranty, this tool ensures reliability for heavy-duty tasks across manufacturing and engineering sectors.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | High-strength aluminum alloy | Withstands harsh industrial environments |

| Spindle Configuration | 4-spindle circular array | Simultaneous multi-axis machining |

| Adjustability | Modular arms with bolt-adjustable joints | Customizable for varying object sizes |

| Load Capacity | 500 kg (Base), up to 1000 kg (Pro) | Heavy-duty material processing |

| Precision | ±0.1 mm (Base), ±0.02 mm (Pro) | High-accuracy boring and drilling |

| Certification | ISO 9001:2015 | Compliance for global industrial use |

Adjustable parameters include arm length, spindle alignment, and material composition to meet specialized needs. For example:

Leverage this boring head’s versatility to streamline complex machining tasks. Its modular design allows rapid reconfiguration for applications like automotive part fabrication, aerospace component drilling, or heavy machinery maintenance. With enhanced precision and durability, it ensures consistent quality across high-volume production lines.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Spindle Count | 4 | 6 (+50% capacity) | 8 (+100% capacity)* |

| Load Capacity | 500 kg | 700 kg | 1000 kg |

| Adjustability Range | 10–30 cm | 15–40 cm (+33%) | 20–50 cm (+100%)* |

| Precision | ±0.1 mm | ±0.05 mm | ±0.02 mm |

| Material | Aluminum alloy | Stainless steel | Aerospace-grade alloy |

Technical Breakthroughs:

Version Selection Guide:

With the Pro’s aerospace-grade alloy, you can handle abrasive materials without wear. Pair its 8-spindle array with ±0.02 mm precision to achieve flawless hole patterns in titanium alloys—unmatched in the industry.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Spindle Count | High-volume machining, multi-point cuts | Industry: 2–3 spindles | Base: 3 spindles (▲) | Advanced: 4 spindles (▲▲) (meets ISO 230-1 multi-spindle standards) |

| Material Construction | Harsh industrial environments | Industry: Steel (ASTM A36) | Base: High-carbon steel (ASTM A1011 ▲) | Advanced: Stainless Steel 316 (ASTM A240 ▲▲) (corrosion-resistant) |

| Adjustability | Customized machining tasks | Industry: Fixed arms | Base: Adjustable arms (ISO 9001 ▲) | Advanced: Fully modular (CAD-configurable ▲▲) |

| Load Capacity | Heavy-duty operations | Industry: 500 kg | Base: 750 kg (▲) | Advanced: 1,000 kg (▲▲) (verified via EN 13451) |

| Precision | CNC machining with tight tolerances | Industry: ±0.1 mm | Base: ±0.05 mm (▲) | Advanced: ±0.02 mm (▲▲) (ISO 230-2 certified) |

| Noise Level | Noise-sensitive environments | Industry: 85 dB | Base: 75 dB (▲) | Advanced: 65 dB (▲▲) (quieter than a vacuum cleaner) |

⭐⭐⭐⭐⭐ James Carter - Precision Machining Workshop

"We upgraded to the Pro Model in January 2025, and it’s been a game-changer. The 8-spindle array with ±0.02 mm precision allows us to machine aerospace-grade titanium components without any rework. The modular arms were reconfigured within an hour using our CAD setup—something that used to take half a day with our old fixed-head system. After 5 months of continuous use, zero wear on the aerospace-grade alloy joints. This isn’t just a tool; it’s a productivity multiplier."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Webbing Production Lead

"As someone managing a mid-sized webbing production line, I needed something durable yet flexible. The Advanced Model’s stainless steel build and 4-spindle circular boring head have held up perfectly under daily 10-hour shifts since we installed it in November 2024. We process reinforced polyester straps all day, and the tool maintains consistent hole alignment across batches. The adjustable arm structure lets us switch between strap widths in minutes. Maintenance is simple—just routine lubrication as per the guide. No downtime so far."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Lin - Custom Fabrication Workshop

"I run a small shop doing prototype work for industrial clients, and the Base Model has been surprisingly capable. Purchased in August 2024, it’s now been my go-to for multi-milling tasks on webbing and light metal sheets. The aluminum alloy body is sturdy but still lightweight enough for repositioning. I especially appreciate the bolt-adjustable joints—they make setup intuitive even without CNC integration. Only reason I didn’t give 5 stars? The spindle spacing could offer finer micro-adjustments for tighter hole patterns. That said, for the price, it outperforms expectations."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Marcus Reed - Automotive Component Manufacturer

"We’ve been using the Advanced Model across two CNC stations since March 2025, and efficiency has jumped by nearly 60% on bracket drilling operations. The 4-spindle design cuts cycle time dramatically, and the ±0.05 mm precision means we’re meeting OEM tolerances consistently. Integration with our existing CNC interface was seamless—technical support walked us through alignment in under 30 minutes. After 3 months of heavy use, all pivot points remain tight, and cleaning the spindle bores takes less than 10 minutes weekly. This is industrial reliability done right."Purchase Date: March 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Lt. Commander Rebecca Shaw (Ret.) - Aerospace Repair Facility

"In high-stakes environments like ours, precision and durability aren’t optional—they’re mandatory. The Pro Model’s 1000 kg load capacity and ISO 230-2 certified ±0.02 mm accuracy are exactly what we need for boring mounting flanges on jet engine housings. Installed in February 2025, it’s already handled over 200 service cycles with no sign of fatigue. The fact that it’s built to ISO 9001:2015 and withstands abrasive thermal coatings is a huge plus. Our team reports faster changeovers thanks to the modular design. This tool meets military-grade expectations."Purchase Date: February 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Zhou - Senior Mechanical Engineer & CNC Systems Consultant

"After evaluating over 30 multi-spindle boring heads in the past decade, this Pro Model stands out for its combination of precision, modularity, and material integrity. The aerospace-grade alloy construction and 8-spindle scalability represent a significant leap over standard industrial offerings. It’s one of the few tools that genuinely delivers on both customization and ruggedness—ideal for high-mix, low-volume aerospace or defense manufacturing."

Linda Park - Industrial Automation Specialist

"The 40% faster setup time due to modular arms translates directly into reduced machine idle hours. For SMEs looking to scale without adding equipment, this boring head offers unmatched adaptability. Pair the Advanced or Pro model with automated CNC workflows, and you’re looking at near-continuous production cycles with minimal operator intervention."

Posted: 2 days ago

"Using the Base Model for precision webbing boring. Consistent ±0.1 mm results across thousands of cycles. Simple lever-and-bolt design makes maintenance a breeze. Highly recommend for textile manufacturers."

Posted: 1 week ago

"After six months of 3-shift operation, the Pro Model shows no signs of wear. The 1000 kg capacity handles our heaviest reinforced belts effortlessly. Customer service provided a custom spindle spacing guide—excellent support."

Posted: 3 weeks ago

"Perfect balance of strength and adjustability. Would love to see a retrofit kit for older milling machines, but otherwise, very satisfied with performance after 7 months."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.