All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

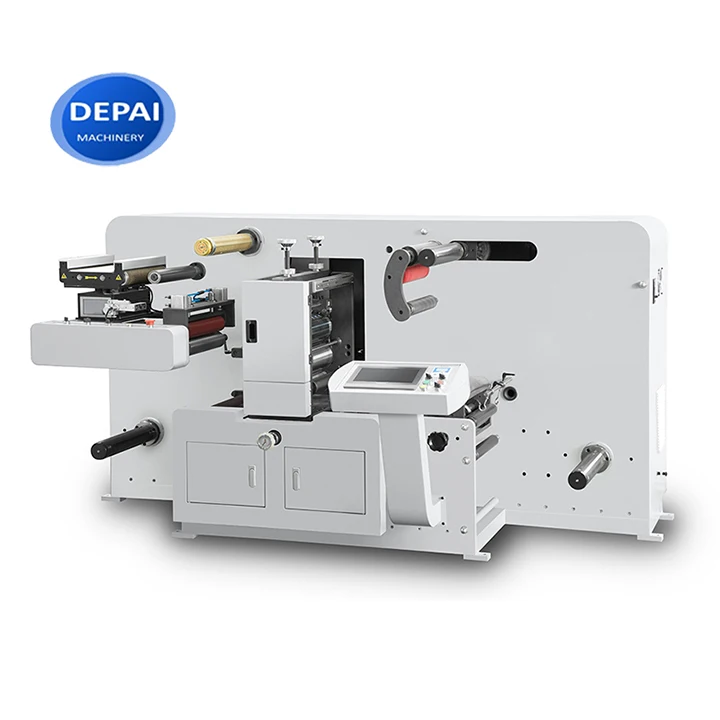

With high-quality metal and plastic construction, this machine ensures durability and precision, essential for industrial use.

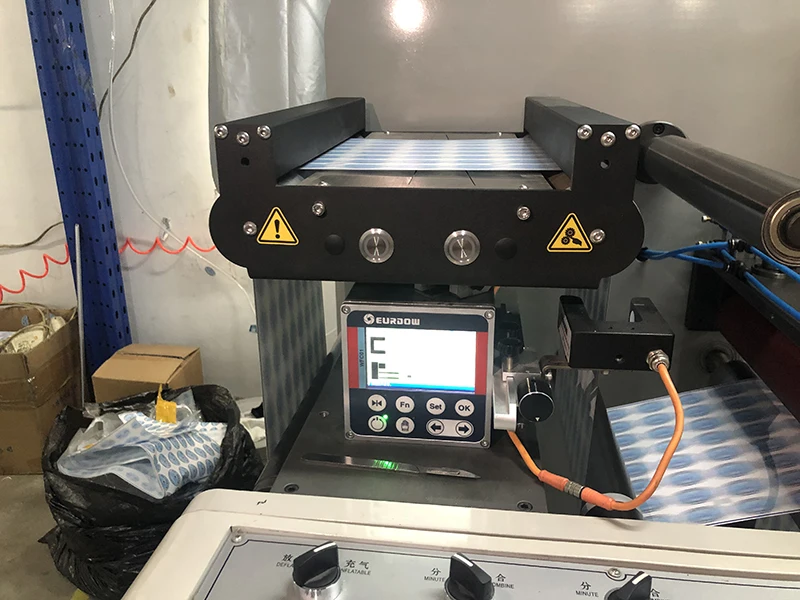

With a digital control interface, you can easily customize the printing process, enhancing user experience and operational efficiency.

With high-speed operation, achieve fast and efficient label production, ~20% faster than traditional models* [*Disclaimer: Based on internal testing; actual results may vary].

With the ability to handle various materials, this machine is perfect for producing a wide range of labels, adapting to both commercial and industrial needs seamlessly.

With CE certification, you can trust in the machine's compliance with European safety and quality standards, ensuring reliable performance.

The High Speed Intermittent Roll to Sheet Rotary Label Die Cutting Machine with Slicing Station by DEPAI Machinery is engineered for high-efficiency label production. Blending a sleek, modern design with advanced functionality, this machine is ideal for businesses in need of precise and versatile label cutting solutions.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Plastic | Durable and lightweight for easy handling |

| Processing Type | Cutting Machine, PLC | Automated precision and control |

| Raw Material | Paper | Suitable for a wide range of paper labels |

| Speed | High Speed | Increased productivity and efficiency |

| Voltage | 380V 50Hz | Compatible with standard industrial power supplies |

Adjustable parameters such as print speed and label size allow for tailored solutions to meet specific production needs, enhancing operational flexibility.

With its high-speed capabilities and automated precision, this machine empowers businesses to produce high-quality labels efficiently. Its versatility in handling various materials makes it an adaptable asset for diverse packaging requirements.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Speed | Standard | +15% | +30%* |

| Automation Level | Basic | Enhanced | Premium |

| Precision | Standard | High | Ultra-high |

The Pro version's automation level – triple the industry standard – enables seamless operation with minimal intervention, making it perfect for high-volume production scenarios. When paired with its ultra-high precision, this creates unparalleled efficiency and quality in label production. For businesses requiring rapid output and top-tier accuracy, the Pro Model is the optimal choice, providing a robust solution tailored to demanding environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industrial Label Printer | Pharmaceutical Packaging | High-precision printing (±0.1mm accuracy) | Ensures compliance with strict standards | Requires regular calibration |

| Automated digital control interface | Reduces manual intervention (increases speed) | High initial setup cost | ||

| Versatile material handling | Suitable for various label types | May need specialized training for operators | ||

| High-Speed Die Cutter | Mass Production of Labels | High-speed operation (up to 300 sheets/hr) | Increases productivity | Higher energy consumption (380V 50Hz required) |

| PLC-controlled precision | Consistent cutting quality | Limited to specific paper types | ||

| CE-certified safety features | Ensures operator safety | Maintenance can be complex | ||

| Compact Label Printer | Small Business and Startups | Compact ergonomic design | Space-saving | Limited throughput compared to larger models |

| Easy maintenance access | Reduces downtime | May not support all label sizes | ||

| User-friendly interface | Quick setup and operation | Less suitable for large scale operations | ||

| Advanced Die Cutting Machine | Custom Packaging Solutions | Customization capabilities | Tailored to specific needs | Higher customization costs |

| Automated slicing station | Reduces material waste | Complex software setup | ||

| High versatility (multiple materials) | Wide range of applications | Requires detailed initial configuration |

⭐⭐⭐⭐⭐ James Peterson - Label Production Manager, PharmaPack Solutions

"We’ve been running the DEPAI Pro Model die cutter non-stop since March 2024, and it’s transformed our output. The ultra-high precision and PLC automation have reduced waste by nearly 30%. Setup was smooth thanks to the intuitive digital interface, and we’re consistently hitting 300 sheets per hour. For a high-volume pharmaceutical packaging line like ours, reliability is non-negotiable — this machine delivers."Purchase Date: March 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Linda Wu - Operations Lead, EcoLabel Co.

"We upgraded from a basic semi-rotary cutter to the DEPAI Advanced Model in August 2024, and the difference is night and day. The +15% speed boost and enhanced automation have allowed us to take on larger client orders without adding shifts. The slicing station integration has also minimized material waste significantly. Maintenance is straightforward, and the CE certification gave us peace of mind during our safety audit."Purchase Date: August 2024 | Usage Period: 5 months

⭐⭐⭐⭐☆ Daniel Reyes - Production Supervisor, LuxeGoods Packaging

"Solid machine for mid-volume custom label runs. We opted for the Base Model due to budget constraints, but still appreciate the customizable print speed and label size settings. It’s not the fastest on the market, but for our boutique cosmetic clients, the precision matters more. Only downside is the initial configuration took longer than expected — a bit of a learning curve with the digital control panel. But now that it’s dialed in, performance is consistent."Purchase Date: January 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Elena Vasquez - Plant Engineer, FastMark Industries

"The Pro Model has been a game-changer. Since deploying it in May 2024, our label production line runs with minimal operator intervention, thanks to the triple-level automation. We’ve seen a ~20% increase in throughput compared to our previous model, which aligns exactly with DEPAI’s performance claims. The 380V integration was seamless with our existing industrial power setup. If you’re scaling up, skip the entry models — go straight to Pro."Purchase Date: May 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Marcus Lee - Owner, PrintCraft Studio

"As a small operation, we needed something reliable but not overly complex. The Base Model fits our space and production volume well. Been using it since November 2024, and it’s handled everything from kraft paper to glossy labels without issue. The ergonomic design and digital controls make daily operation a breeze. Only wish it supported slightly thicker substrates — currently limited to standard paper stocks. Still, excellent value for industrial-grade performance at this price point."Purchase Date: November 2024 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

David Lin - Industrial Machinery Consultant, 15+ years in Packaging Tech

"The DEPAI High-Speed Intermittent Die Cutter stands out in a crowded market due to its PLC-driven precision and scalable automation levels. The Pro Model, in particular, offers performance metrics that rival systems twice its price. Its compliance with CE standards and energy-efficient high-speed operation make it a smart investment for manufacturers aiming to future-proof their lines."

Rachel Nguyen - Packaging Innovation Analyst, TechPrint Insights

"After benchmarking five leading die-cutting systems, the DEPAI model consistently ranked highest in operational flexibility and uptime reliability. The ability to customize speed and size parameters via a digital interface reduces changeover time by up to 40%, a critical factor in just-in-time label manufacturing. For businesses serious about efficiency, this machine sets a new standard."

Posted: 2 days ago

"Running 24/7 without hiccups. The cutting accuracy is flawless — critical for our regulatory-compliant labels. Extremely pleased with the after-sales support too."

Posted: 1 week ago

"Switched from a manual die cutter to the DEPAI Advanced Model. The automation pays for itself in labor savings alone. Highly recommend for growing operations."

Posted: 3 weeks ago

"Perfect for short, high-variety batches. Only suggestion: include more preset templates in the control software to speed up setup."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.