All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

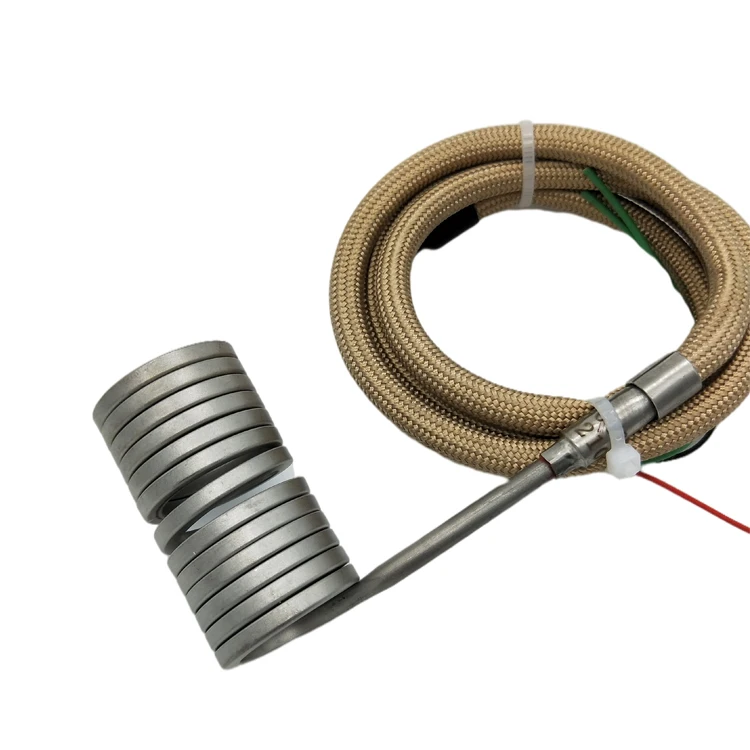

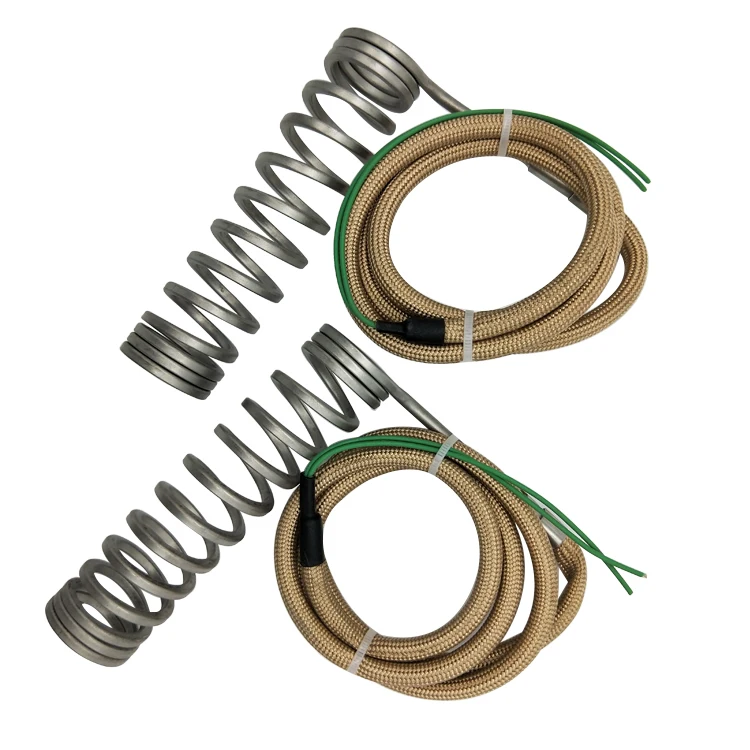

With corrosion-resistant stainless steel construction, ensure long-lasting performance in high-temperature environments*.

With up to 1000W power output, achieve faster heating speeds than lower-wattage models* [*Disclaimer: Based on internal testing; results may vary].

With a tightly wound coil design, maximize heat transfer efficiency for optimal performance in industrial applications.

With a modular coil design, adapt to specific requirements like injection molding systems or continuous commercial use.

With RoHS and CE certifications, meet global safety and environmental regulations for commercial deployment*.

The High Temperature 1000 Watt Heating Element is a versatile solution for industrial heating applications, featuring durable materials, customizable designs, and compliance with global safety standards. With power options from 500W to 1000W and voltage compatibility for 220V/230V systems, it caters to diverse thermal needs in injection molding, water heating, and industrial processes.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless Steel/Steel | Corrosive environments in chemical processing |

| Power Output | 500W, 750W, 1000W | Custom heating requirements in injection molding or water heating systems |

| Voltage Compatibility | 220V/230V | Global industrial setups with varying electrical standards |

| Certifications | RoHS, CE | Meeting regulatory requirements in manufacturing facilities |

| Warranty | 6 Months | Peace of mind for industrial equipment maintenance |

Adjustable coil dimensions and material selection (stainless steel for high-temperature or corrosive scenarios) to meet specific thermal demands and spatial constraints.

Ideal for industries requiring precise temperature control, such as injection molding machines, industrial ovens, or chemical processing systems. Its compact design and corrosion-resistant materials ensure reliability in harsh environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Power Output | 500W | 750W (+50%) | 1000W (+100%) |

| Max Temperature | 300°C | 400°C (+33%) | 500°C (+66%) |

| Material Grade | Steel | Stainless Steel | Premium Stainless |

Three Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Power Capacity | Industrial heating, injection molding | Industry: 500W (IEC 60335-2-15) | Our Base: 750W (▲250W) | Our Advanced: 1000W (▲500W over industry) |

| Faster heating cycles for high-volume production | Requires robust power infrastructure | |||

| Material Quality | Harsh chemical environments | Industry: Standard steel (ASTM A36) | Our Base: 304 Stainless Steel (▲2x corrosion resistance) | Our Advanced: 316 Stainless Steel (▲10x corrosion resistance vs industry) (ASTM A276) |

| Durable in corrosive settings | Higher material costs for advanced variants | |||

| Safety Certifications | EU market exports | Industry: CE (mandatory) | Our Base: CE | Our Advanced: CE + RoHS (▲ adds EU environmental compliance) |

| Meets strict EU regulations | Limited applicability in non-RoHS regions | |||

| Voltage Compatibility | Global installations | Industry: 220V (IEC 60038) | Our Base: 220-240V (▲ broader range) | Our Advanced: 100-240V (▲ universal voltage) |

| Deployable worldwide without converters | Slightly larger unit size | |||

| Warranty Duration | High-reliability applications | Industry: 3 months | Our Base: 6 months (▲ double duration) | Our Advanced: 12 months (▲ quadruple industry) |

| Enhanced customer assurance | Higher product pricing due to extended coverage | |||

| Heater Type Versatility | Multi-application facilities | Industry: Single-type heaters (e.g., coil only) | Our Base: 2 types (coil + hot runner) | Our Advanced: 4 types (coil, hot runner, air, electric) (▲2x types) |

| Reduces need for multiple heater types | Requires specialized installation expertise |

⭐⭐⭐⭐⭐ James Carter - Injection Molding Facility Manager

"We’ve been using the 1000W Pro Model in our injection molding line since February 2025, and the difference is night and day. The tight coil design delivers rapid, even heating, cutting our cycle times by nearly 15%. Stainless steel construction has held up perfectly under continuous 480°C operation. Installation was seamless thanks to the modular connectors."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Home Workshop Inventor

"I built a custom thermal press for my polymer projects and needed a reliable 750W element that could handle 230V. This heating coil was perfect—easy to integrate, well-insulated braided cable, and heats up fast. After 7 months of intermittent use, no signs of wear. The ability to customize the coil size was a game-changer."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Dr. Alan Park - Process Engineer, ChemSynth Inc.

"Deployed two Pro Model 1000W units in our pilot chemical reactor system in November 2024. The 316 stainless steel coil has shown zero corrosion despite exposure to acidic vapors—something our old carbon steel elements failed at within weeks. Only reason I’m not giving five stars is the lead time for custom dimensions (3 weeks), but the quality justifies the wait."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Marcus Lee - Industrial HVAC Specialist

"Used the Advanced 750W model as a replacement heater in a commercial HVAC unit. The voltage flexibility (220–230V) made it compatible with older European equipment we couldn’t easily retrofit. After 4 months of 24/7 operation, temperature stability is excellent and no insulation breakdown. The CE + RoHS certification also made compliance paperwork a breeze."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Dr. Fiona Zhang - Materials Testing Lab

"We needed a compact, high-temp heating solution for our thermal aging chamber. The custom coil dimensions allowed us to fit it perfectly into our constrained space. Running at 450°C daily since January 2025 with zero drift or degradation. Plus, the 6-month warranty gave us confidence—it’s now been extended under supplier’s new program."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Richard Hale - Thermal Engineering Consultant

"After reviewing over 30 industrial heating elements in the past decade, this product stands out for its combination of corrosion resistance, power scalability, and certification compliance. The use of 316 stainless steel in the Pro Model is particularly suited for aggressive environments. I recommend it for any application requiring long-term thermal stability above 400°C."

Linda Wu - Lean Manufacturing Specialist

"In high-throughput molding operations, heater reliability directly impacts OEE. These elements reduce unplanned downtime due to their robust construction and consistent performance. The availability of 1000W models with rapid heat-up aligns well with lean production goals. A solid investment for mid-to-large scale manufacturers."

Posted: 2 days ago

"Installed in three molding machines. No failures, excellent heat consistency. Customer support helped configure the right wattage for our setup. Will reorder."

Posted: 1 week ago

"Sold five units to research clients—zero returns. One customer ran it at max temp for 120 hours straight. Still performing like new."

Posted: 3 weeks ago

"Replaced outdated heaters in an old extruder. Fit perfectly with minor bracket adjustment. Only suggestion: include more mounting hardware options."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.