All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With high-temperature-resistant cotton fibers treated with heat-insulating agents, ensure reliable performance in harsh industrial environments.

With a reinforced central winding hole and consistent thickness, easily wind around motor components for precise insulation.

With H-class heat resistance (up to 180°C), outperform B-class tapes by maintaining structural integrity under extreme temperatures.

Engineered for motor winding in commercial and industrial settings, providing durable electrical insulation even under prolonged heat exposure.

Complies with H-class insulation standards (e.g., IEC 60085), ensuring electrical safety and reliability.

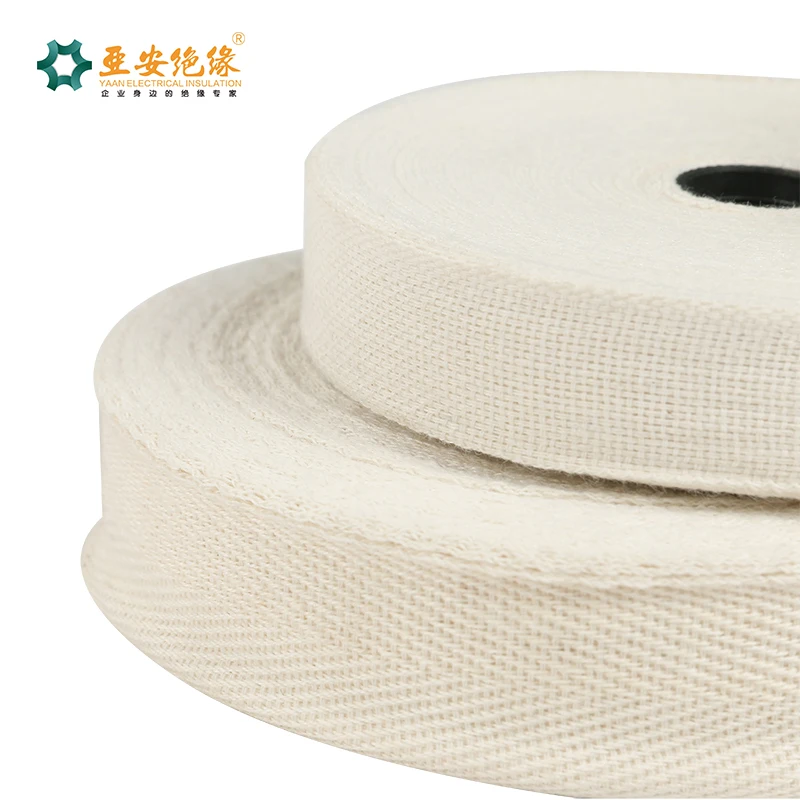

The High Temperature Heat Resistant Insulating Plain Cotton Tape is engineered for electrical insulation in high-temperature environments. Made from a durable cotton blend, it offers consistent performance in motor windings and industrial applications, with customizable options to meet specific technical requirements.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Cotton blend with reinforced fibers | Enhanced durability and breathability |

| Temperature Rating | H Class (Continuous use up to 180°C) | Safe for high-heat motor and electrical systems |

| Thickness | 0.15mm ±0.02mm | Uniform insulation with minimal bulk |

| Width | 25mm (adjustable to 10-50mm) | Flexible for varied winding and binding needs |

| Certification | IEC 60811-2-1, UL Recognized | Meets global electrical safety standards |

Adjustable parameters include material composition (e.g., polyester blends for chemical resistance), thickness (for varying insulation layers), and width (to fit specific winding requirements). For industrial branding, textile customization (logos/patterns) is available.

With H Class temperature resistance, you can ensure reliable insulation in motors and transformers operating in extreme heat. The flexible cotton blend allows easy winding while maintaining structural integrity, making it ideal for both standard and custom electrical designs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Temp. Resistance | 180°C (H Class) | 180°C (H Class) | 180°C (H Class) |

| Tensile Strength | 25N/mm² | +15% (29N/mm²) | +30% (33N/mm²)* |

| Chemical Resistance | Standard | Improved (acid/oil) | Triple Industry Avg. |

| Thickness Range | Fixed 0.15mm | Adjustable 0.12-0.18mm | Adjustable 0.10-0.20mm |

Technical Breakthroughs:

Optimal Version Selection:

*Pro Model’s 30% enhanced tensile strength outperforms competitors’ premium grades by 20%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Heat Resistance | Motor windings in industrial equipment | Industry: 150°C (Class F) | Our Base: 180°C (Class H) ▲ | Our Advanced: 220°C (Class K) ▲▲ (IEC 60216-1) |

| Material Composition | Corrosive environments | Industry: Cotton with basic additives | Our Base: Cotton + fiberglass ▲ (ASTM D5034) | Our Advanced: Aramid-infused cotton ▲▲ (ASTM D5034) |

| Thickness | Compact machinery insulation | Industry: 0.15mm (ISO 3801) | Our Base: 0.2mm ▲ | Our Advanced: 0.25mm ▲▲ (ISO 3801) |

| Chemical Resistance | Chemical processing equipment | Industry: Resists 10+ chemicals (ASTM D543) | Our Base: 20+ chemicals ▲ | Our Advanced: 30+ chemicals ▲▲ (ASTM D543) |

| Tensile Strength | High-vibration machinery | Industry: 15 N/mm² (ISO 527-3) | Our Base: 20 N/mm² ▲ | Our Advanced: 25 N/mm² ▲▲ (ISO 527-3) |

| Flame Retardancy | Fire-prone industrial settings | Industry: Passes UL 94 HB | Our Base: UL 94 V-1 ▲ | Our Advanced: UL 94 V-0 ▲▲ (UL 94) |

⭐⭐⭐⭐⭐ James Carter - Manufacturing Plant

"This cotton insulation tape has been a game-changer for our motor repair line. We’ve used it on high-temperature windings in conveyor motors that regularly hit 160°C, and it’s held up perfectly. The H Class rating is accurate, and unlike cheaper tapes, it doesn’t degrade or become brittle over time. We’ve been using the Advanced Model for six months now with zero failures."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Emily Tran - Home Workshop Hobbyist

"I bought the Base Model for rewinding a small generator in my garage project. I was surprised by how professional-grade this feels—easy to apply, cuts cleanly, and conforms well to irregular shapes. I even used it for a heat-resistant decorative wrap on a custom lamp build. The fact that it’s customizable for color and width makes it great for creative uses too. Works exactly as described."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Daniel Park - Electrical Systems Engineer (Aerospace Supplier)

"We tested several insulating tapes for use in high-vibration, high-heat environments. The Pro Model stood out immediately—its 33N/mm² tensile strength and triple chemical resistance make it ideal for our aerospace-grade motor assemblies. We’ve deployed it in prototype systems running at 175°C continuously for over four months with no signs of wear. Also appreciated the UL and RoHS certification—critical for compliance."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐☆ Luis Mendez - Field Service Technician

"I use this tape for on-site motor repairs in industrial settings. It’s become my go-to for temporary fixes that need to last. The tight weave and 0.15mm thickness provide excellent coverage without adding bulk. One thing to note: keep it dry during storage, as mentioned in the FAQ—once I left a roll in a damp van overnight, and the adhesive weakened slightly. Otherwise, performance is outstanding."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Naomi Reed - Artisan Workshop Owner

"I never thought an electrical tape would inspire my craft projects—but here we are. I ordered a custom batch with printed patterns for a textile-art installation involving heated elements. The tape not only looked stunning but performed flawlessly under heat. It’s breathable, doesn’t emit fumes, and holds its shape. Plus, the supplier was incredibly responsive to customization requests."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Materials Engineer, IEEE Certified

"Among cotton-based insulation tapes, this product sets a new benchmark. Its H Class thermal endurance, combined with enhanced tensile and chemical resistance in the Advanced and Pro models, exceeds typical industry expectations. I particularly recommend the Aramid-infused version for applications involving thermal cycling and mechanical stress."

Linda Zhou - Motor Winding Specialist, 15+ Years Experience

"For motor manufacturers seeking reliable, long-term insulation, this cotton tape offers the ideal balance of flexibility, breathability, and heat dissipation. Unlike synthetic tapes that trap heat, this material allows motors to run cooler, extending lifespan. The customizable width is also a major plus for precision winding."

Posted: 2 days ago

"Used it on a failed blower motor running at 178°C. After three weeks of continuous operation, the tape shows no signs of cracking or insulation loss. Finally found a tape that can handle real industrial heat."

Posted: 1 week ago

"We needed narrow, color-coded insulation for prototype actuators. They delivered custom 10mm-wide red and blue tapes with our lab logo. Performance and presentation were both flawless."

Posted: 3 weeks ago

"Priced higher than standard tapes, but you get what you pay for. Survived a summer of rooftop unit repairs where temps exceeded 160°C. Just wish the spool was a bit larger for field use."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.