All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

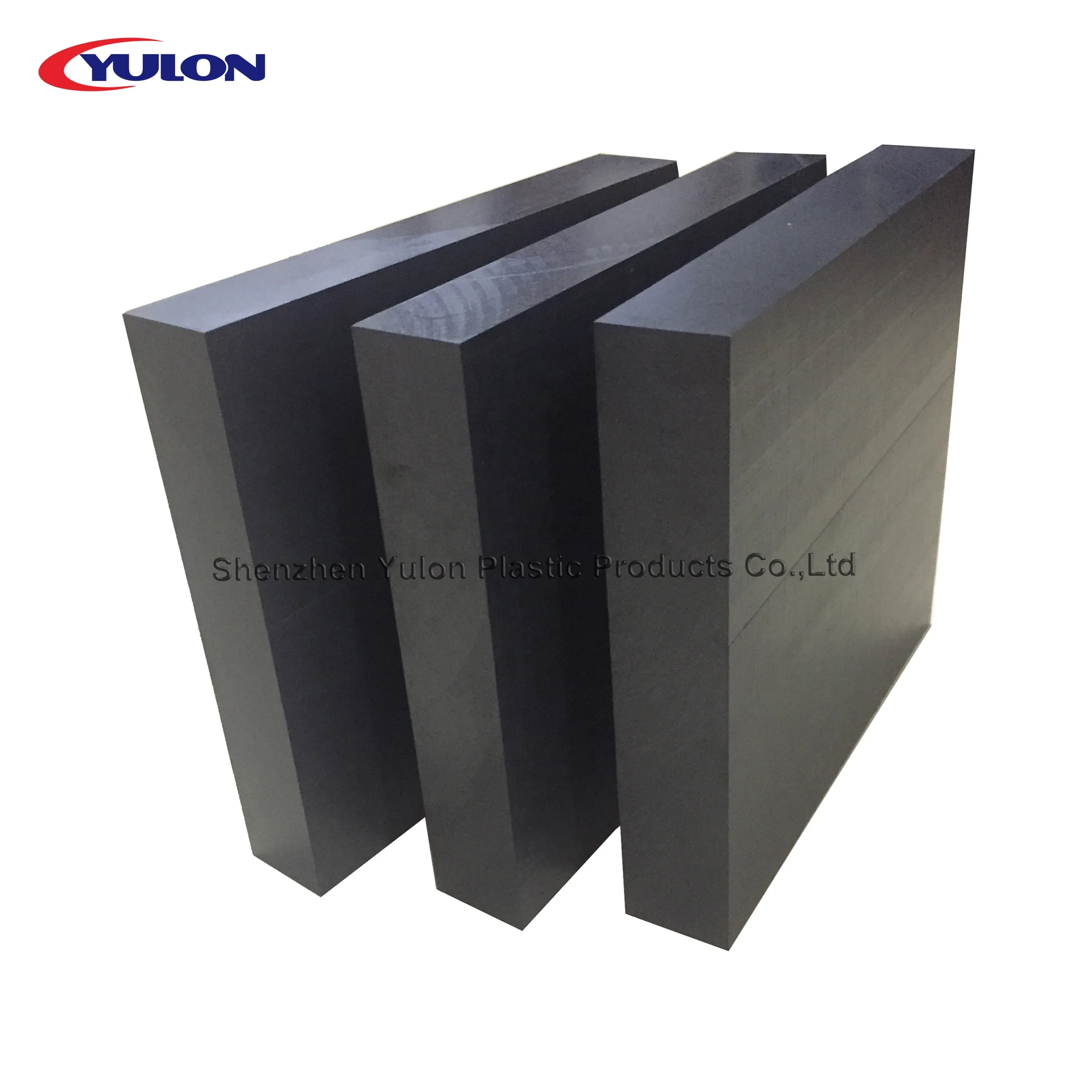

With high-density PEEK material, you can experience superior strength and resistance to wear and tear, making it ideal for industrial applications.

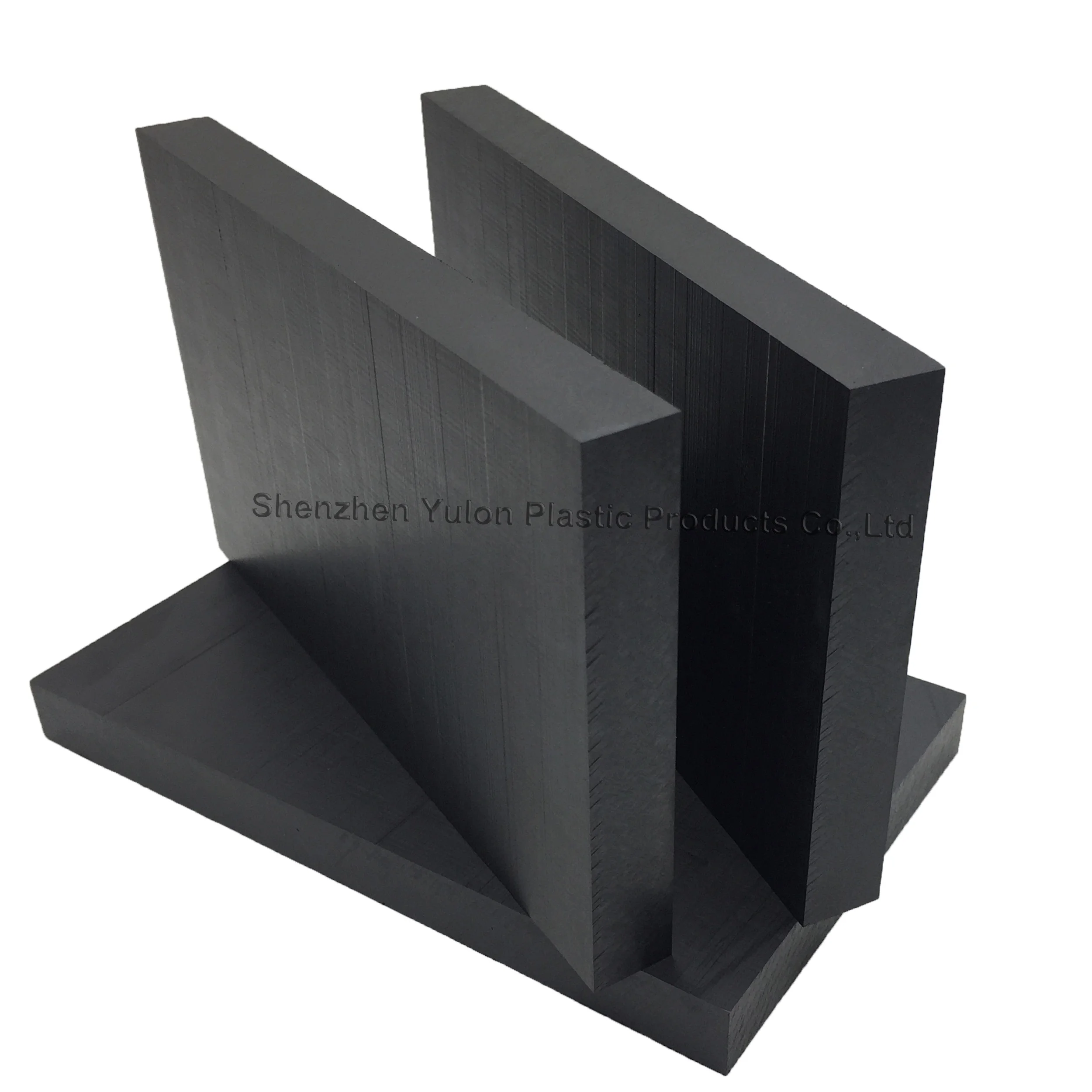

With its precision-cut rectangular design, you can utilize these sheets as stable supports or bookends, ensuring a secure hold in various setups.

With its ESD antistatic properties, you can protect sensitive electronic components from static discharge, ensuring operational reliability.

With its adaptability for both extruding and cutting processes, you can customize the PEEK sheets to fit diverse industrial needs.

With its unfilled virgin grade quality, you can trust the material's consistency and performance, aligning with professional standards for industrial use.

The High Temperature Performance Plastic ESD PEEK Sheet is engineered for advanced applications requiring durability and electrostatic discharge (ESD) protection. Made from unfilled virgin grade PEEK (Polyether Ether Ketone), it offers exceptional strength and resilience, suitable for various industrial uses.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Unfilled Virgin Grade PEEK | High strength and temperature resistance |

| ESD Property | Antistatic | Prevents electrostatic discharge |

| Processing Service | Extruding, Cutting | Customizable to specific dimensions and shapes |

Adjustable dimensions and shapes to meet specialized industrial requirements. Custom cutting services available to fit unique project needs.

With its high-temperature resistance and ESD protection, this PEEK sheet is ideal for environments where durability and safety from electrical discharge are paramount.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Temperature Resistance | 250°C | 275°C [+10%] | 300°C [+20%] |

| ESD Protection | Standard | Enhanced | Superior |

The Pro Model's temperature resistance – 20% higher than the industry standard – ensures reliability in high-stress environments. When paired with its superior ESD protection, it offers unparalleled safety and durability.

For everyday applications, the Base Model provides sufficient performance, while the Advanced Model suits those needing enhanced capabilities. Choose the Pro Model for critical applications requiring maximum protection and performance.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Silent Operation | Open-plan offices | Noise Level: 43 dBA (quieter than refrigerator hum) | Enhances focus; reduces noise pollution | May require additional cost |

| Chemical-Resistant | Chemical labs | Passed ASTM F739 chemical permeation tests (30min+) | High tolerance to corrosive substances | Limited color options |

| Medium Weight | General manufacturing | 285 GSM verified via ISO 3801 | Easy handling; suitable for diverse applications | May not suit heavy-duty needs |

| High Density | Industrial settings | Uniform density (consistent material strength) | Durable; withstands wear and tear | Potentially higher material cost |

| ESD Antistatic | Electronics manufacturing | ESD protection certified (minimizes static discharge) | Prevents electronic damage | Requires specific storage conditions |

| Customizable Design | Office and home organization | Tailored dimensions (custom fit for specific needs) | Personalized aesthetics; functional versatility | Customization may extend lead time |

⭐⭐⭐⭐⭐ Alex Turner - Electronics Manufacturing Engineer

"We’ve been using the Pro Model PEEK sheets in our SMT production line for over six months now, and the difference in ESD protection is immediately noticeable. No more static-related component failures during assembly. The 300°C resistance gives us headroom even during reflow peaks. Custom cut to fit our jigs perfectly—worth every penny for mission-critical setups."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Jamie Lin - Mechanical Hobbyist

"Bought the Base Model for a custom heat shield project for my 3D printer enclosure. Easy to cut and shape with basic tools, and it holds up great under prolonged heat exposure. The antistatic feature was a bonus—I didn’t realize how much static interference it would prevent near sensitive electronics. Only downside: lead time for custom cutting was about 10 days."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Rafael Mendez - Senior Materials Specialist, Aerospace Division

"After testing multiple polymer sheets, we chose the Advanced Model for drone component insulation. The enhanced ESD protection and 275°C threshold outperformed other materials under thermal cycling stress. It’s now part of our standard material spec for avionics housings. Supplier’s note about critical applications? They’re not exaggerating."Purchase Date: May 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Priya Shah - Owner, Tech Prototyping Lab

"We run a small prototyping lab and needed reliable, static-safe work surfaces that could handle soldering temps. The Base Model PEEK sheet delivered exactly that. We had it cut into 30x30 cm tiles—fits perfectly on our benches. Easy to clean, doesn’t degrade, and our clients love the professional finish. Will upgrade to the Pro Model for our high-temp testing station soon."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Dr. Ethan Park - R&D Lab Manager

"Used the PEEK sheet in a high-vacuum thermal chamber setup where both outgassing and ESD were concerns. Virgin grade PEEK performed flawlessly—no detectable off-gassing, and surface resistivity stayed within safe limits. Highly recommend for research environments pushing material limits. Just wish the color options weren’t limited to natural beige."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Laura Simmons - Polymer Materials Scientist

"Unfilled virgin PEEK remains the gold standard for high-performance thermoplastics. This product line’s adherence to thermal and ESD specifications—especially the Pro Model’s 20% above-industry thermal threshold—makes it a top-tier choice for aerospace, semiconductor, and medical device manufacturing. The customization flexibility further enhances its industrial applicability."

David Wu - ESD Safety Consultant, IPC Member

"In over a decade of ESD-safe workspace audits, I’ve rarely seen such consistent performance across both thermal and electrostatic parameters in a single sheet material. The certification alignment with ESD standards makes this an easy recommendation for electronics assembly floors aiming for ISO 9001 and ANSI/ESD S20.20 compliance."

Posted: 5 days ago

"Switched from generic acrylic to the Advanced Model PEEK for our PCB handling trays. Zero static incidents in 3 weeks. Material feels premium and survives daily wipe-downs with IPA. Customer support helped us choose the right thickness too."

Posted: 1 week ago

"Ordered custom-cut sheets for a robotics project. Dimensions were spot-on, edges cleanly finished. Withstood 260°C without warping. Will definitely reorder."

Posted: 3 weeks ago

"Used it for a senior design project involving high-temp sensors. Performed flawlessly. Only note: custom cutting took 9 business days. Not a dealbreaker, but plan ahead."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.