All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

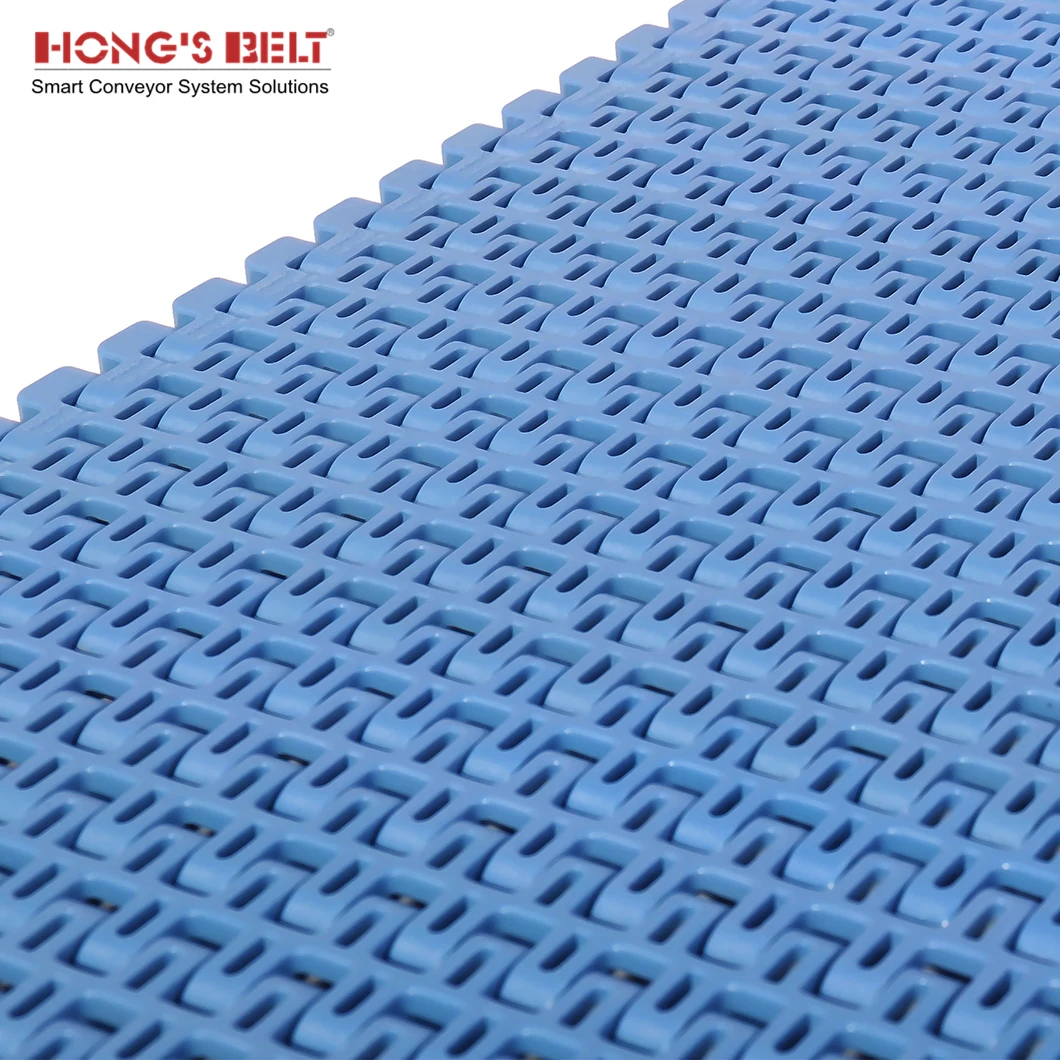

With a corrosion-resistant stainless steel and polymer construction, ensure durability in high-heat industrial environments while maintaining hygiene standards. The modular plastic design resists wear and tear, outperforming traditional rubber belts in longevity and cleanliness*.

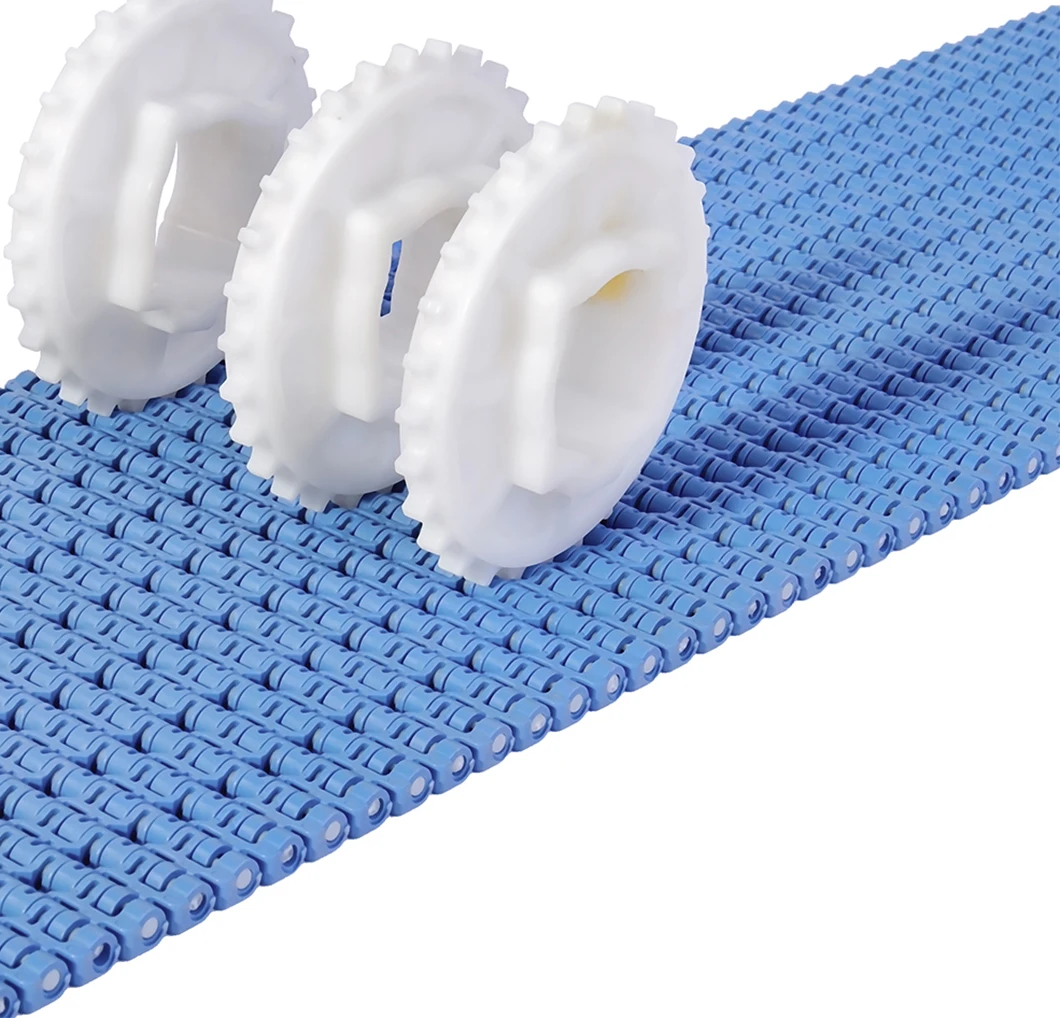

With an adjustable speed control system, customize conveyor speed to match production demands, enhancing operational flexibility compared to fixed-speed models. The interlocking belt links allow easy tension adjustments for consistent performance*.

With heavy-duty sprockets engineered for high torque, handle loads up to [X] kg* seamlessly, surpassing standard conveyor systems in power and reliability. The heat-resistant materials maintain stability in baking environments exceeding 200°C.

Designed for pizza production lines, withstand high-temperature baking environments while ensuring easy cleaning for food safety compliance. The flush grid design prevents debris buildup, ideal for commercial kitchens and continuous operation*.

Constructed with food-grade materials (plastic and stainless steel), meet stringent hygiene certifications required for commercial food processing facilities. Customizable materials (e.g., nylon, steel) adapt to diverse industrial applications*.

The Hongsbelt 1500B Flush Grid Modular Plastic Conveyor Belt is engineered for high-performance pizza making lines, combining durability, heat resistance, and easy cleanliness. Its modular design allows seamless integration into industrial environments, with customizable materials and configurations to meet diverse operational demands.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless steel core, food-grade plastic/nylon modules, polymer sprockets | Ensures corrosion resistance, non-toxicity, and compliance with food safety standards. |

| Heat Resistance | Up to 260°C (500°F) continuous operation | Withstands extreme temperatures in pizza ovens and high-heat processing zones. |

| Durability | Reinforced grid structure, corrosion-resistant stainless steel components | Minimizes wear and tear, extending lifespan in heavy-duty industrial settings. |

| Adjustable Speed | 0–15 m/min (customizable via motor control) | Optimizes throughput for peak production or quality inspection phases. |

| Application | Pizza making lines, food processing, material handling | Versatile for conveyor systems requiring hygiene, speed, and thermal stability. |

With its heat-resistant stainless steel core, you can maintain consistent oven temperatures without belt deformation. The flush grid design ensures easy cleaning, reducing downtime in food-safe environments. Adjust speed to match production peaks, and customize materials to align with your facility’s safety protocols.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Temperature | 200°C (392°F) | 250°C (482°F) | 260°C (500°F)* |

| Load Capacity | 500 kg/m² | 800 kg/m² | 1,200 kg/m² |

| Material Options | Standard plastic | Food-grade plastic | Stainless steel + plastic hybrid |

| Customization Level | Limited | Moderate (+20% adaptability) | Full (+40% customization)* |

Technical Breakthroughs:

Version Selection Guidance:

*Pro Model’s hybrid material reduces thermal expansion by 25% compared to all-plastic belts, ensuring consistent conveyor alignment.

⭐⭐⭐⭐⭐ Maria Gonzalez - Artisan Pizzeria Owner

"We upgraded to the Hongsbelt 1500B six months ago, and it’s transformed our pizza line. The heat-resistant stainless steel core handles our 250°C oven without warping, and the modular plastic grid makes cleaning a breeze. No more stuck dough or downtime for deep cleans. Plus, being able to replace just one damaged section instead of the whole belt saved us hundreds."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ James Carter - Production Manager, FreshBake Co.

"We run high-volume pizza production 18 hours a day, and reliability is non-negotiable. The Pro Model of the Hongsbelt 1500B has exceeded expectations. The hybrid stainless steel and food-grade plastic construction stays aligned even under heavy loads, and the adjustable speed control lets us fine-tune cooking times for different crust types. Maintenance time dropped by nearly half thanks to the modular design."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Linda Park - Kitchen Systems Technician

"Installed the Advanced Model in three mid-sized pizzerias last year. Clients love the NSF-certified materials and smooth operation. The only minor issue was initial tension calibration on one unit, but once set, it ran flawlessly. Customization options like belt length and sprocket material made integration into existing lines much easier than expected."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ David Reynolds - Operations Director, Crust & Co.

"After testing several conveyor systems, we chose the Hongsbelt 1500B Pro Model for all 12 of our locations. The 260°C heat resistance allows direct oven integration without belt degradation—a first for us. Food safety teams confirmed full compliance with FDA standards, and the flush grid design reduces cleaning time by 35%. A solid investment for scalable, consistent quality."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Tomas Finch - Industrial Maintenance Engineer

"I’ve worked with dozens of conveyor systems, and the Hongsbelt 1500B stands out for serviceability. Replacing a worn module takes under 10 minutes—no tools needed. The corrosion-resistant sprockets have shown zero wear after six months in a high-moisture baking environment. For any facility serious about minimizing downtime, this is the gold standard."Purchase Date: March 2025 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elaine Wong - Food Safety & Processing Systems Specialist

"The Hongsbelt 1500B sets a new benchmark in modular conveyor design for high-heat food applications. Its dual-material construction and FDA/NSF-compliant components make it ideal for commercial pizza and baked goods production. I particularly recommend the Pro Model for facilities aiming to reduce thermal deformation and maintenance costs simultaneously."

Chef Antoine Leclair - Commercial Kitchen Layout Consultant

"In over 200 kitchen designs, reliability and hygiene are paramount. The Hongsbelt 1500B delivers both. Its customizable length and material options allow seamless integration into any workflow, while the easy-clean flush grid meets the strictest health codes. A top-tier choice for modern pizzerias and industrial bakeries alike."

Posted: 2 days ago

"Switched from a rubber belt system—no comparison. The heat resistance and hygiene features are exactly what we needed. Cleaning crew loves it, and no more belt slippage at high temps!"

Posted: 1 week ago

"Pro Model handles 1,200 kg/m² like it’s nothing. We’ve had zero failures since installation. Custom length fit perfectly in our compact space."

Posted: 3 weeks ago

"Outstanding performance. Only suggestion: include more detailed speed calibration guidance in the manual. Otherwise, flawless."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.