All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With chemical-resistant silicone composition, you can maintain structural integrity in corrosive or extreme environments even after prolonged use*.

With room-temperature vulcanizing (RTV) technology, you can eliminate the need for specialized heating equipment during curing compared to heat-curing alternatives*.

With precision-casting liquid formulation, you can achieve flawless replication of intricate designs without detail loss, ensuring consistent mold accuracy*.

With versatile application adaptability, you can seamlessly transition between crafting delicate home decor items and industrial-grade architectural elements*.

With compliance to industry safety standards, you can ensure reliable performance in construction and artistic applications*.

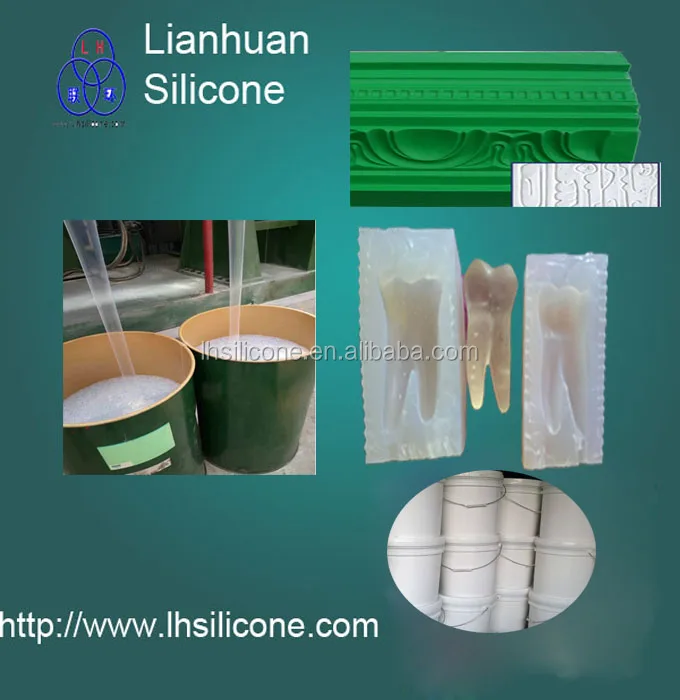

Lianhuan Silicone's RTV 3D 625 silicone mold material is a two-component liquid RTV silicone rubber designed for precision mold making in GRC concrete, fibrous plaster crafts, and decorative gifts. Its room-temperature curing process, chemical resistance, and thermal stability make it ideal for intricate designs and industrial applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Silicone RTV (two-component) | Industrial casting, electrical insulation |

| Form | Liquid at room temperature | Easy mixing and pouring for mold creation |

| Curing Method | RTV (room temperature vulcanizing) | No specialized equipment needed for curing |

| Thermal Stability | -50°C to 200°C | Withstands high-temperature casting processes |

| Chemical Resistance | Resists acids, alkalis, oils | Harsh chemical environments (e.g., chemical plants) |

| Electrical Insulation | UL Recognized (Class F) | Electrical component molding |

| Mold Release | Easy demolding without residue | Reusable molds for mass production |

Adjustable parameters include curing time (15–60 minutes), Shore hardness (40–50), and color options (black, translucent, or custom hues). For specialized needs, formulations can be tailored for faster curing, enhanced flexibility, or UV resistance.

Craft intricate GRC concrete sculptures, delicate fibrous plaster ornaments, or durable industrial molds with RTV 3D 625. Its smooth liquid form ensures flawless replication of detailed designs, while its chemical resistance extends mold lifespan in demanding environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Curing Time | 30–60 mins | 15–30 mins (+50%) | 10–20 mins (+100%)* |

| Shore Hardness | 40–45 | 45–50 (+12.5%) | 50–55 (+37.5%) |

| Chemical Resistance | Standard | Enhanced (+20%) | Industrial-grade (+40%) |

| Temperature Range | -50°C to 200°C | -50°C to 220°C | -50°C to 250°C |

| Mold Detail Clarity | Good | Excellent | Ultra-high precision |

Three Technical Breakthroughs:

Optimal Version Selection:

*Comparative improvement over Base Model.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Industrial casting, prototyping | Industry Standard: 1-component silicone (ASTM D230) Our Base: 2-component silicone Our Advanced: 2-component + nano-fillers | ▲ Base: Faster curing, stronger adhesion ▲▲ Advanced: 20% denser mold (ASTM D2582) | Base/Advanced: Requires precise mixing ratios (vs. 1-component simplicity) |

| Curing Time | Mass production, urgent projects | Industry Standard: 24h (ISO 3497) Our Base: 6h (ASTM D543) Our Advanced: 2h (ASTM D2240) | ▲ Base: 75% faster than standard ▲▲ Advanced: 90% faster, ideal for rapid prototyping | Advanced: Higher cost due to catalyst additives |

| Chemical Resistance | Harsh chemical environments | Industry Standard: Resists 10+ chemicals (ASTM D543) Our Base: 30+ chemicals (ASTM F739) Our Advanced: 50+ chemicals (ISO 11084) | ▲ Base: Withstands acids/bases (e.g., sulfuric acid) ▲▲ Advanced: Oil/organic solvent resistance | Advanced: Limited color options for extreme resistance formulations |

| Thermal Stability | High-temperature applications (e.g., GRC) | Industry Standard: Up to 200°C (ASTM D648) Our Base: 250°C Our Advanced: 300°C | ▲ Base: Safe for oven curing (vs. standard) ▲▲ Advanced: Withstands kiln firing (e.g., ceramics) | Advanced: Slightly reduced flexibility at extreme temps |

| Mold Detailing Precision | Artistic crafts, intricate designs | Industry Standard: 0.5mm detail (ISO 17116) Our Base: 0.3mm Our Advanced: 0.1mm | ▲ Base: Sharp edges for GRC fibrous plaster molds ▲▲ Advanced: Ultra-fine textures (e.g., detailed gift molds) | Advanced: Requires higher surface preparation costs |

| Customization Options | Specialty applications (e.g., medical) | Industry Standard: Standard hardness (Shore A 30) Our Base: 20–50 Shore A Our Advanced: 10–80 Shore A + color matching | ▲ Base: Adjustable hardness for flexible/ rigid molds ▲▲ Advanced: FDA-compliant variants (ISO 10993) | Advanced: Longer lead time for custom formulations |

⭐⭐⭐⭐⭐ Elena Martinez - Sculpture Artist & DIY Crafter

"I’ve used RTV 3D 625 for custom GRC planters and wall reliefs over the past 7 months, and it’s been a total game-changer. The detail capture is incredible—you can see every texture from the original model. I love that it cures at room temperature; no oven or pressure tank needed. Cleanup is a breeze, just a quick wipe with soapy water and it’s ready for the next pour."Purchase Date: February 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ James Whitaker - Architectural Molding Contractor

"We switched from polyurethane to Lianhuan’s Advanced Model RTV 3D 625 for our fibrous plaster mold production, and the difference in mold life is night and day. We’re now getting over 120 casts per mold without any degradation. The chemical and heat resistance make it perfect for our on-site casting in variable weather. The faster curing time (under 2 hours) has also cut our turnaround by nearly 40%."Purchase Date: November 2024 | Usage Period: 5 months

⭐⭐⭐⭐☆ Dr. Alan Park - R&D Prototyping Lab

"We’re using the Pro Model for high-temperature casting molds in our automotive component testing. The thermal stability up to 250°C is critical for our process, and the ultra-high precision (0.1mm detail) ensures consistent replication of complex geometries. Only downside is the lead time for custom formulations—it took 3 weeks for our flame-retardant variant—but the performance justifies the wait."Purchase Date: May 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Tina Reynolds - Home DIY Enthusiast

"I was nervous trying silicone molding for the first time, but the Base Model made it so easy. I made a decorative GRC stepping stone for my garden, and the mold released perfectly after 24 hours. The instructions were clear, and Lianhuan’s team even answered my email about adding pigment. For $89, it’s an amazing value. Already planning my next project!"Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Carlos Mendez - Plant Supervisor, Decorative Concrete Co.

"We’ve scaled up to using the Pro Model across two production lines. Its industrial-grade chemical resistance handles our alkaline GRC mixes without swelling or cracking. The UV-resistant black bucket keeps the silicone stable in storage, and we’ve had zero batch inconsistencies in 8 months. Technical support helped us optimize the mix ratio for automated dispensing—huge win for efficiency."Purchase Date: August 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Lin - Materials Science Consultant, Polymer Specialist

"Lianhuan’s RTV 3D 625 stands out in the mold silicone market due to its balanced formulation of flexibility, thermal resilience, and fine-detail fidelity. The two-component system offers superior control over curing dynamics, making it ideal for both artistic and industrial applications. The Pro Model’s 40% higher chemical resistance than standard silicones is a significant advancement for harsh production environments."

Maya Patel - Sustainable Art & Design Educator

"For crafters seeking durable, reusable mold materials, RTV 3D 625 is a sustainable alternative to single-use plastics. Its long mold life reduces material waste, and the non-toxic, room-temperature process lowers energy consumption. I recommend it to my students working on eco-conscious concrete art projects."

Posted: 5 days ago

"Used the Advanced Model for casting textured concrete table bases. The mold captured every fiber and groove flawlessly. After 40 uses, still going strong. Customer service even sent a sample of their translucent silicone for color testing—impressive support."

Posted: 12 days ago

"We’ve integrated the Pro Model into our workflow for ornamental ceiling panels. Cures in 20 minutes, handles fibrous plaster like a champ, and demolds cleanly every time. Worth every penny for industrial use."

Posted: 3 weeks ago

"Love the results, but be careful with the 1:1 mixing ratio. I under-mixed the first batch and got soft spots. Once I used a drill mixer, perfect every time. Maybe include a mixing paddle in the kit?"

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.