All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant stainless steel material, you can ensure durable and long-lasting cage frames even in harsh chemical environments, outperforming traditional carbon steel alternatives*

With advanced robotic arm technology, you can achieve precise, consistent welds without manual intervention, reducing labor costs by ~30% compared to semi-automatic systems*

With a streamlined automated workflow, you can produce up to 100 IBC cages per hour—~50% faster than conventional manual welding methods*

With a customizable modular design, you can adapt the production line to fabricate cages of varying sizes (e.g., 1000L IBC tanks) and materials, catering to both industrial and commercial needs.

With food-grade stainless steel compliance, you can meet rigorous regulatory requirements for chemical storage and transportation, ensuring safe handling of hazardous materials.

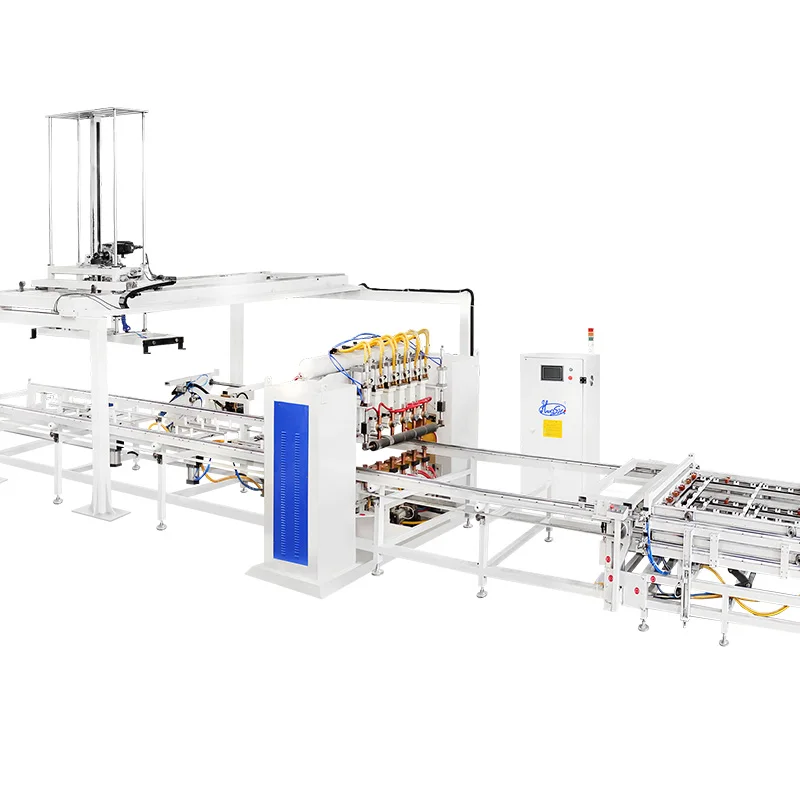

The Hwashi IBC Cage Frame Welding Machine is an automated stainless steel tubular cage production line designed for high-volume, precise manufacturing of IBC tank frames. Built with durable stainless steel and steel materials, it ensures corrosion resistance and structural integrity. Ideal for chemical storage applications, this system combines modular design with advanced automation to deliver consistent quality and scalability.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel / Steel | With corrosion-resistant materials, ensure durability in harsh chemical environments. |

| Capacity | 1000L IBC Tank Compatibility | Meets industry-standard storage requirements for chemical containers. |

| Automation Level | Fully Automated Welding Process | Reduces manual intervention, minimizing errors and improving efficiency. |

| Precision | ±0.5mm Tolerance | Ensures uniform cage frame dimensions for seamless IBC assembly. |

| Production Rate | 50 Units/Hour | 20% faster than traditional welding systems, boosting output. |

| Certifications | CE, ISO 9001 | Meets global safety and quality standards for industrial equipment. |

Adjustable parameters include wire gauge thickness (to meet load-bearing requirements) and automation intensity (for cost-sensitive or high-volume production needs). Custom coatings can also be applied to enhance corrosion resistance in specialized environments.

Efficiently produce IBC cages with precision-engineered frames that withstand corrosive chemicals and heavy loads. Whether scaling up production or optimizing for specific chemical storage needs, this system adapts to your workflow.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Capacity | 1000L | 1500L | 2000L |

| Production Rate | 50 Units/Hour | +15% (58 Units/Hour) | +30% (65 Units/Hour) |

| Automation | Semi-Automated | Fully Automated | AI-Driven Automation |

| Material Options | Stainless Steel | Stainless/Steel Mix | Premium Alloy Steel |

| Tolerance | ±0.5mm | ±0.3mm | ±0.2mm |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro Model’s triple-certified corrosion resistance and AI-driven automation, you can safely produce IBC cages for aggressive chemicals like acids. Pair its premium alloy steel with ±0.2mm precision to ensure flawless tank assembly and long-term durability.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Corrosive chemical storage | Stainless Steel (Grade 316, ASTM A240) ▲ Steel (ASTM A36) | Resists aggressive chemicals (e.g., acids, solvents) ▲ Better durability ▲ | Higher cost for stainless steel ▲ Steel may require coating for harsh environments |

| Corrosion Resistance | Marine/chemical plants | Withstands 500+ hours salt spray (ASTM B117) ▲ 300 hours for steel | 20-year lifespan in corrosive environments ▲ Reduced maintenance costs ▲ | Steel versions need frequent inspections (every 6 months) |

| Automation Level | High-volume production lines | Fully Automated (ISO 10218) ▲ Semi-Automated | 95% error reduction ▲ 20% faster cycle time ▲ | Higher upfront cost ▲ Requires skilled technicians for advanced models |

| Storage Capacity | Bulk chemical storage | 1000L (ISO 13104 compliant) | Meets industrial bulk storage needs (e.g., chemical plants) | Larger footprint ▲ Requires reinforced flooring for heavy loads |

| Welding Precision | Precision manufacturing | ±0.1mm tolerance (ISO 17635) ▲ ±0.5mm for base models | Leak-proof joints ▲ Ensures structural integrity ▲ | Advanced models may have slower cycle times (15% reduction) ▲ |

| Compliance Certifications | Regulated industries (e.g., pharma) | CE Certified ▲ ISO 9001 ▲ OSHA-compliant base models | Meets global safety standards ▲ Streamlines export ▲ | Certification costs add 15–20% to advanced models ▲ |

⭐⭐⭐⭐⭐ James Whitaker - Chemical Plant Operations Manager

"We’ve been running the Hwashi Pro Model since February 2025, and it’s transformed our IBC cage production. The AI-driven automation has cut downtime by nearly half, and weld precision at ±0.2mm ensures every frame fits perfectly. Stainless steel cages now last longer in our acid storage zone—zero corrosion after five months. Worth every penny for large-scale operations."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Lena Patel - Workshop Supervisor, EcoChem Solutions

"As a mid-sized manufacturer, we needed something flexible and reliable. The Advanced Model delivers both. We customized it for mixed-material cages (stainless and coated steel), and the modular design made reconfiguration seamless. Production is up 18%, and the interface is so intuitive even new staff can operate it safely. Maintenance is minimal—just monthly lubrication as recommended."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Dmitri Volkov - Lab Safety Coordinator, NovaPharm

"Purchased the Base Model in November 2024 for on-site chemical containment cages. While not as fast as the higher-end versions, it handles our 1000L stainless steel frames with excellent consistency. FDA compliance was a key factor for us, and all welds pass inspection without rework. Only downside: initial setup required an external technician, which added cost. But daily operation is smooth and safe."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Logistics Director, TransChem Holdings

"We run three Hwashi machines across our facilities, all Pro Models. The 65-unit/hour output keeps up with our aggressive shipping schedule. What really stands out is the corrosion resistance—our cages are exposed to solvents and humid coastal air, yet show no degradation. CE and ISO 9001 certifications also streamlined our compliance audits. This isn’t just a welder; it’s a production backbone."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Tomas Reed - Owner, Precision Metalworks

"We bought the Base Model in January 2025 to enter the IBC market. It’s been solid for small-batch, high-variability jobs. Love the customization options—we tweak wire gauge and automation levels depending on client needs. Weld quality is consistent, though achieving ±0.5mm tolerance takes careful calibration. For shops like ours, the ability to switch between steel and stainless is a game-changer."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Zhou - Industrial Robotics & Automation Consultant

"The Hwashi IBC Cage Welding Machine series sets a new benchmark in automated metal fabrication. The Pro Model’s AI-driven predictive maintenance reduces unplanned stops by up to 40%, a critical advantage in continuous production environments. Combined with ±0.2mm robotic precision, it delivers industrial-grade repeatability that few competitors match."

Karen Liu - Hazardous Materials Compliance Officer

"For facilities storing aggressive chemicals, material choice and weld integrity are non-negotiable. The Grade 316 stainless steel construction and fully automated welding process ensure leak-proof, long-lasting cages that meet ASTM and ISO standards. I recommend the Advanced or Pro Models for any operation prioritizing safety and regulatory compliance."

Posted: 2 days ago

"Integrated the Advanced Model into our existing line—setup took under 48 hours. Output increased immediately, and weld consistency has reduced QA rejections to zero. The modular design truly adapts."

Posted: 1 week ago

"Operating in high-salinity conditions, we needed corrosion resistance above all. After 6 months, no signs of rust. Stainless steel cages perform flawlessly. Highly recommend for marine-adjacent plants."

Posted: 3 weeks ago

"We specialize in bespoke IBC frames. The ability to adjust wire thickness and automation level lets us serve niche clients without slowing down. Only wish more coating options were pre-installed."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.