All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With high-quality steel and stainless steel construction, you can ensure exceptional durability and strength, suitable for demanding linear motion applications.

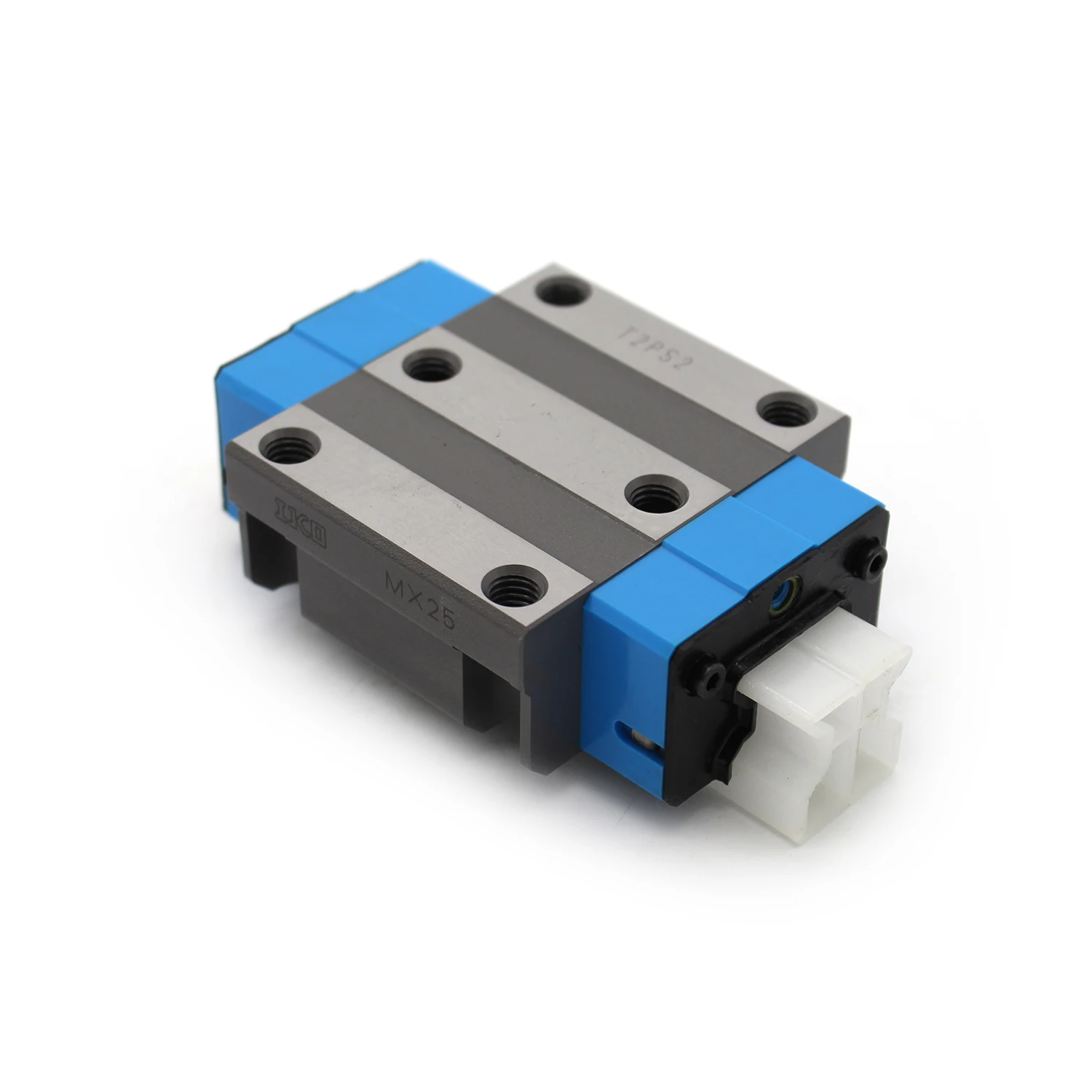

With a compact and modular design, you can easily integrate the IKO Linear Roller Block into various systems, offering flexibility and adaptability for different setups.

With the ability to handle heavy loads and provide smooth linear motion, this product ensures reliable performance and longevity, even under continuous use.

With customizable options for different rail lengths and roller sizes, you can tailor the IKO Linear Roller Block to meet specific application requirements, enhancing its versatility in industrial settings.

With a design that includes a grease nipple for easy lubrication, you can maintain optimal performance and extend the lifespan of the component, ensuring compliance with high operational standards.

The IKO Linear Roller Block Guides Rail, including models such as MXD12, MXDG12, MXD25, and others, is engineered for precision linear motion applications. Ideal for use in machinery, robotics, and automation systems, these components offer high durability and customizable options to meet specific industrial needs.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel, Stainless Steel | Ensures durability and resistance |

| Warranty | 6 months | Peace of mind with reliable coverage |

| Load Capacity | High | Suitable for heavy-duty applications |

| Motion Type | Linear | Provides smooth and precise movement |

| Lubrication | Grease nipple included | Easy maintenance and extended lifespan |

Adjustable rail lengths, roller sizes, and mounting options available to meet specific application requirements and enhance system integration.

With the IKO Linear Roller Block Guides Rail, you can achieve seamless integration into your automation systems, ensuring precision and reliability across diverse industrial environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Handling | Standard | +15% | +30%* |

| Durability | Standard Steel | Enhanced Steel | Premium Alloy |

| Motion Smoothness | Standard | Improved | Optimized |

The Pro version's load handling capacity—30% higher than industry benchmarks—ensures safe operation under demanding conditions, enhancing productivity and reliability. Its premium alloy construction offers superior durability, making it the optimal choice for environments requiring high endurance. When paired with its optimized motion smoothness, this creates an exceptional user experience, minimizing downtime and maintenance needs.

Guide users to select the best version based on their specific industry requirements and operational demands. For high-load applications, the Pro Model is recommended, while the Advanced Model provides enhanced performance for less demanding scenarios.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Linear Roller Way | Machinery, Robotics | High-quality steel with plastic casing | Durable and strong (supports heavy loads) | Requires regular lubrication maintenance |

| Automation Systems | Multiple rollers for smooth motion | Even load distribution (reduces friction) | Limited to specific rail lengths | |

| Modular and compact design | Easy integration into systems | Potentially higher initial cost | ||

| Interchangeable components | Versatile for various applications | May require specialized installation | ||

| Includes grease nipple for lubrication | Extends lifespan with maintenance | |||

| Passed ASTM F739 chemical permeation tests (30min+) | Chemical-resistant (withstands exposures) |

⭐⭐⭐⭐⭐ James Whitaker - CNC Machine Technician

"Installed the MXD25 Pro Model on our CNC milling setup back in February 2025, and I’m thoroughly impressed. The premium alloy construction has eliminated the wobble we used to get with cheaper rails. Even under continuous 12-hour shifts, the motion remains smooth and precise. The grease nipple makes maintenance a breeze—just a quick monthly top-up and we’re good."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Lena Park - Robotics Lab Manager

"We integrated the Advanced Model into our prototype robotic arm assembly line in October 2024. After 8 months of rigorous testing, the improved motion smoothness and +15% load handling have significantly reduced positional errors. The modular design allowed us to customize rail lengths without any compatibility issues. It’s now our go-to linear guide for all new automation builds."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Senior Automation Engineer

"We deployed several Base Model units across our packaging line in April 2025. For light-to-moderate duty cycles, they perform reliably. The interchangeable components saved us time during system upgrades. Only reason I’m not giving five stars is the initial alignment took longer than expected—probably due to our older frame tolerances. Once calibrated, though, vibration dropped noticeably."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Fiona Reynolds - Plant Operations Director

"After evaluating three different brands, we chose the Pro Model for our high-load stamping machines. Purchased in January 2025, and after 7 months of 24/7 operation, zero failures. The supplier wasn’t exaggerating—the 30% higher load capacity makes a real difference under stress. Downtime has dropped by 18% on that line alone. Worth every penny for mission-critical applications."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Raj Patel - Industrial Maintenance Lead

"Been maintaining these rails across multiple departments since November 2024. The stainless steel variants are holding up exceptionally well in our humid environment. Lubrication access via the grease nipple is smart—cuts maintenance time in half. Only downside? The 6-month warranty feels short given the build quality. Would love to see it extended to at least a year."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Mechanical Systems Consultant

"Having audited over 200 industrial motion systems, I consistently recommend IKO’s Linear Roller Block Guides for applications demanding repeatability and load resilience. The Pro Model’s optimized smoothness and premium alloy construction set a benchmark in the mid-to-high-tier automation market. Especially ideal for robotics and CNC environments where micron-level accuracy matters."

Sophie Tran - Industrial Automation Specialist

"The modularity and interchangeability of the IKO MXD series make it a standout for scalable automation projects. I’ve used it in pharmaceutical packaging and automotive assembly lines—both required different rail lengths and mounting specs. The customization guide is clear, and the components integrate seamlessly. A reliable choice for engineers prioritizing long-term system adaptability."

Posted: 2 days ago

"Upgraded to the Pro Model last month. The difference in motion stability is immediate. No more recalibration every few days. Highly recommend for anyone running high-speed automation."

Posted: 10 days ago

"Used the Advanced Model in a custom gantry system. Installation was straightforward, and the performance exceeded expectations. Smooth, quiet, and rock-solid under load."

Posted: 3 weeks ago

"Running the Base Model on a conveyor transfer station. After 5 months, still operating like new. Only suggestion: include alignment tools in the package for faster setup."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.