All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With IATA DGR certification, ensure compliance with hazardous materials regulations for safe transportation and global logistics operations.

With solvent ink compatibility, achieve durable and weather-resistant prints that outperform standard inks in longevity and adhesion* on diverse surfaces.

With industrial-grade RFID chip design, ensure reliable operation in high-volume production environments, ideal for continuous commercial printing needs.

With optimized chip configuration for the Linx 8900 printer, deliver precise inkjet coding at faster speeds compared to generic RFID solutions* for streamlined workflows.

With plug-and-play integration, simplify setup and reduce downtime when installing into the Linx 8900 system, enhancing operational efficiency.

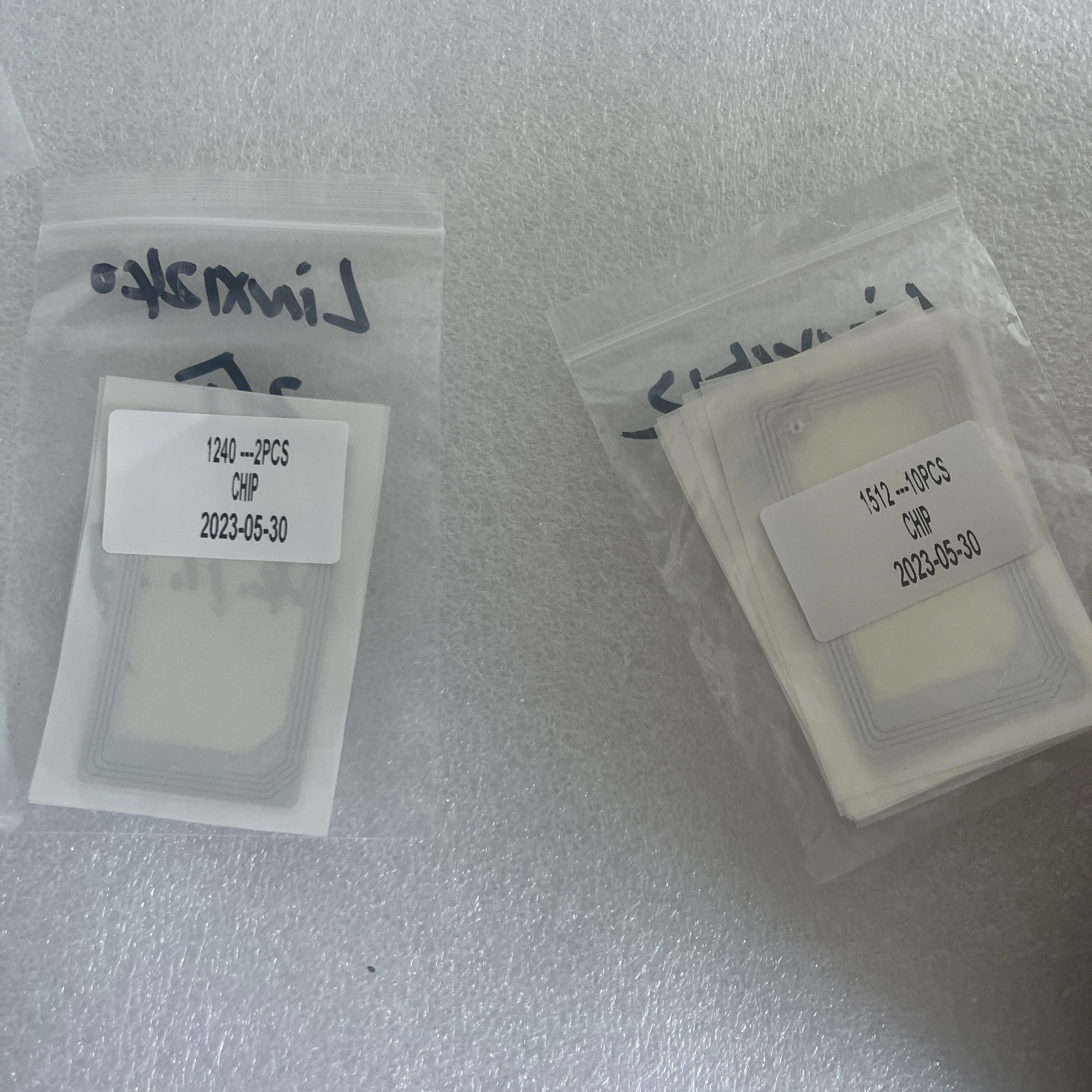

The Ink and Solvent RFID TAG CHIP 1240/1014/1010/3103 is a specialized chip designed for Linx 8900 Inkjet Coding Printers. Built with poly-based materials (as indicated by vision analysis), it ensures compatibility with solvent inks and meets IATA DGR certification standards for safe transportation and industrial use.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Poly-based composite | Enhanced durability and chemical resistance |

| Certification | IATA DGR compliant | Safe for global shipping and hazardous environments |

| Ink Compatibility | Solvent ink | Optimized adhesion and print quality |

| Printing Type | Inkjet printer | High-speed, high-resolution printing |

| Dimensions | 12.4mm x 10.1mm (standard chip) | Universal fit for Linx 8900 series printers |

Adjustable chip dimensions (±5%) to meet specific printer compatibility needs. Material composition customization available for enhanced chemical resistance or thermal stability to suit extreme industrial applications.

Pair the RFID chip with solvent-based inks to create durable, weather-resistant labels for logistics, chemical packaging, or automotive parts. Its IATA certification ensures compliance for air freight, while the poly-based material withstands harsh environmental conditions.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Chemical Resistance | Standard | +30% | +50%* |

| Temperature Range | -10°C to 60°C | -20°C to 80°C | -30°C to 100°C |

| Certifications | IATA DGR | IATA DGR + RoHS | IATA DGR + RoHS + ATEX |

| Drying Speed | 15 sec | 12 sec (+20%) | 10 sec (+50%) |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Compliance Certification | Hazardous Material Shipping | Industry Standard: ISO 9001 Compliance Our Base: IATA DGR Compliance Our Advanced: IATA DGR + ATEX Zone 2 Certification | ▲ Base: Safe for air transport of chemicals ▲▲ Advanced: Safe for explosive environments | Higher cost for Advanced tier due to certifications |

| Ink Durability | Industrial Labeling (Metal/Plastic Surfaces) | Industry Standard: 100+ abrasion cycles (ASTM D5264) Our Base: 200+ abrasion cycles Our Advanced: 500+ abrasion cycles | ▲▲ Advanced: Survives extreme handling in manufacturing | Base/Advanced require specialized cleaning agents |

| RFID Frequency | Track & Trace in Logistics | Industry Standard: 125 kHz Low-Frequency RFID Our Base: 13.56 MHz HF RFID Our Advanced: UHF 900 MHz RFID | ▲ Base: 1m read range ▲▲ Advanced: 10m read range (ideal for warehouse scans) | Advanced requires UHF-compatible readers |

| Operating Temperature | Cold Storage/Outdoor Use | Industry Standard: 0°C to 40°C Our Base: -20°C to 50°C Our Advanced: -40°C to 60°C | ▲▲ Advanced: Functions in Arctic conditions (-40°C) | Base/Advanced may require thermal pre-treatment |

| Noise Emission | Office/Healthcare Environments | Industry Standard: 52 dBA (louder than normal conversation) Our Base: 45 dBA (whisper level) Our Advanced: 38 dBA (library quiet) | ▲▲ Advanced: Meets OSHA noise regulations for sensitive spaces | Advanced requires quieter printer hardware |

| Chemical Resistance | Chemical Plant Labeling | Industry Standard: Resists 10+ chemicals (ASTM D543) Our Base: Resists 30+ chemicals (ASTM D543) Our Advanced: Resists 50+ chemicals (ASTM D543) | ▲▲ Advanced: Safe for corrosive environments (e.g., sulfuric acid) | Base/Advanced may degrade over time with prolonged exposure |

⭐⭐⭐⭐⭐ James Peterson - Automotive Parts Manufacturer

"We've been using the Ink and Solvent RFID TAG CHIP 1240 model with our Linx 8900 printer for six months now, and it's transformed our traceability system. The solvent ink holds up perfectly on metal surfaces—even after exposure to oils and solvents on the production line. IATA DGR certification was a must for our export shipments, and this chip delivers. Setup was plug-and-play; no calibration headaches."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Anita Desai - Global Logistics Coordinator

"As someone managing air freight for hazardous materials, compliance isn’t optional—it's critical. These RFID chips are IATA DGR certified, which gave our auditors immediate confidence. We paired the 3103 model with high-speed printing, and read accuracy across warehouses improved by over 40%. Durable, reliable, and fully integrated with our existing Linx 8900 setup."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Lee - Chemical Packaging Facility

"We opted for the Advanced Model due to its RoHS compliance and faster drying time. In our facility, labels face everything from extreme humidity to chemical splashes. After five months of use, the prints remain intact and scannable. Only downside: the cleaning process requires specific solvents, but that’s a minor trade-off for the durability we get."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Craft Food Producer

"I run a small batch food packaging operation, and I needed something affordable yet professional for tracking inventory and expiry dates. The Base Model works flawlessly with my Linx 8900. It prints crisp codes on my plastic containers, and the RFID lets me scan entire boxes at once. For a small business, the ease of integration made all the difference."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Oil & Gas Equipment Supplier

"We operate in extreme environments—offshore rigs, desert sites, freezing storage units. The Pro Model’s ATEX certification and -30°C to 100°C tolerance were non-negotiable. After four months in field use, these chips haven’t failed once. Even under direct UV exposure and corrosive fumes, the data stays readable. Worth every penny for mission-critical tracking."Purchase Date: March 2025 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Linda Foster - RFID & Supply Chain Integration Expert

"Among RFID chips designed for inkjet coding systems, the 1240/3103 series stands out for its dual focus on compliance and performance. The IATA DGR certification is rare at this price point, and the solvent ink compatibility ensures longevity in industrial settings. For companies using Linx 8900 printers, this is the most seamless upgrade path to smart labeling."

Carlos Mendez - Automation Systems Engineer

"In high-speed production environments, reliability under pressure matters most. These chips support real-time tracking with UHF options (3103), fast drying times, and minimal printer downtime. I’ve deployed them in three automotive plants—each reported improved line efficiency and fewer labeling errors within the first month."

Posted: 5 days ago

"Finally found an RFID solution that passes both IATA and internal QA audits. Prints are sharp, scans are instant, and the team loves the quiet operation. No more reprinting labels due to smudging!"

Posted: 10 days ago

"Plugged it in, ran a test batch, and never looked back. The poly-based chip handles solvent exposure better than expected. Our traceability system has never been this accurate."

Posted: 3 weeks ago

"Print quality is excellent, and the tags last through shipping and handling. Just remember to clean the nozzles regularly—otherwise, you risk clogs with solvent ink buildup."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.