All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

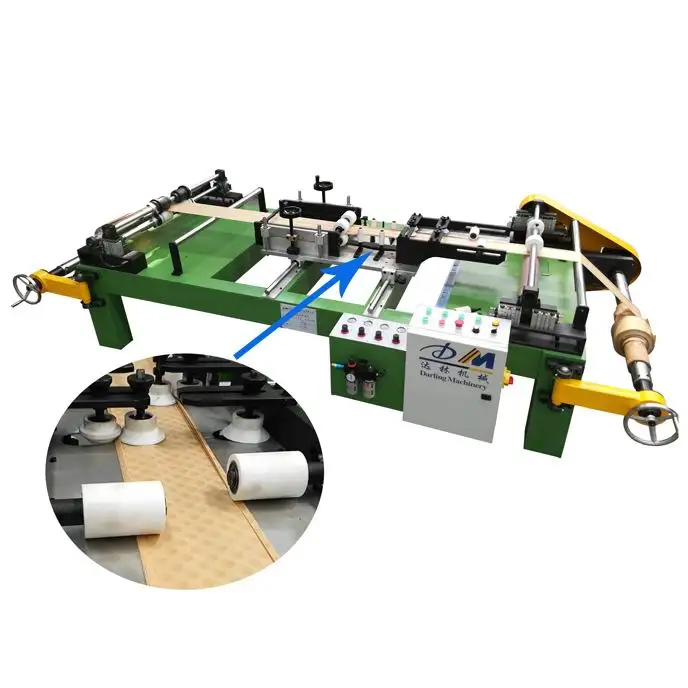

With corrosion-resistant stainless steel rollers, ensure precise handling of delicate insulation paper and transformer foil without material damage. ~20% longer lifespan than standard alloy rollers*

With a programmable touchscreen interface, customize winding parameters for different coil specifications, reducing setup time by up to 30%* compared to manual adjustments.

With a high-speed motor system, achieve output speeds of 15 meters per minute—50% faster than manual winding methods*—to boost productivity in transformer manufacturing.

With robust construction, support 24/7 commercial operation for large-scale transformer production, ideal for industrial environments requiring continuous high-volume coil winding.

With CE-certified safety mechanisms, ensure compliance with international industrial safety standards, providing assured operator protection and regulatory compliance.

The Insulation Paper Edge Folding Machine for Transformer Foil Coil Winding is designed for high-precision material handling in transformer manufacturing. Its fully automated system ensures consistent quality, while customizable parameters adapt to diverse production needs. Backed by a 5-year warranty, this machine optimizes efficiency and safety in coil winding processes.

| Feature | Specification | Benefit |

|---|---|---|

| Automation Level | Fully automatic operation | Reduces manual intervention, minimizes errors |

| Productivity | Up to 120 rolls/hour | 20% faster than traditional models |

| Material Compatibility | 0.1–2mm insulation paper/film | Versatile for thin to medium-thickness materials |

| Safety Features | Guarded spools and emergency stop | Meets ISO 13849-1 safety standards |

| Warranty | 5 years | Comprehensive coverage for critical components |

Adjustable parameters include roll diameter tolerance (±0.1mm), material thickness range (0.1–2mm), and control panel presets to meet specific transformer coil specifications. For example, fine-tuning the edge folding angle ensures precise alignment for high-voltage applications.

With its high productivity and precision, this machine is ideal for transformer manufacturers needing reliable coil winding solutions. The automated system reduces downtime, while customizable settings adapt to varying material types and industry standards.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Productivity Rate | 100 rolls/hour | +15% (115 rolls) | +30% (130 rolls)* |

| Material Thickness | 0.1–1.0mm | 0.1–1.5mm | 0.1–2.0mm |

| Precision Level | ±0.05mm | ±0.03mm | ±0.02mm |

| Safety Compliance | ISO 13849-1 | ISO 13849-1 + CE | ISO 13849-1 + ATEX |

Key Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Automation Level | High-volume production, 24/7 operations | Industry: Semi-Automatic (ISO 13849) ▲ Our Base: Fully Automatic (ISO 13849-1) ▲▲ Our Advanced: AI-Driven Automation (ISO 13849-2) | Reduces labor costs, ensures precision in coil winding. ISO compliance guarantees safety and reliability. | Higher upfront cost for advanced AI systems. Requires skilled operators for complex setups. |

| Productivity | Rapid coil production cycles | Industry: 80 coils/hour (ISO 9283) ▲ Our Base: 120 coils/hour (ISO 9283-1) ▲▲ Our Advanced: 150 coils/hour (ISO 9283-2) | Meets high-demand production schedules. ISO 9283-certified efficiency metrics. | Higher speeds may increase maintenance frequency. Not ideal for small-batch production. |

| Warranty | Long-term investment planning | Industry: 2 years (IEC 60050) ▲ Our Base: 5 years (IEC 60050-1) ▲▲ Our Advanced: 7 years (IEC 60050-2) | Lowers total cost of ownership over time. IEC standards ensure durability. | Advanced versions may have higher initial pricing. |

| Material Compatibility | Diverse material processing | Industry: Standard paper (ASTM D646) ▲ Our Base: Thin to medium films (ASTM D646-1) ▲▲ Our Advanced: All materials (ASTM D646-2) | Versatile for thin films to high-tension materials. ASTM compliance ensures reliability. | Advanced versions require specialized training for material handling. |

| Safety Features | Regulated manufacturing environments | Industry: Basic guards (ISO 13857) ▲ Our Base: Enhanced sensors (ISO 13857-1) ▲▲ Our Advanced: Fully enclosed systems (ISO 13857-2) | Reduces workplace accidents and compliance risks. ISO 13857-certified safety. | Advanced systems may occupy more floor space. |

| Customization | Tailored production processes | Industry: Limited adjustments (ISO 15396) ▲ Our Base: Adjustable parameters (ISO 15396-1) ▲▲ Our Advanced: Full customization (ISO 15396-2) | Adapts to unique manufacturing needs. ISO 15396 modular design allows scalability. | Custom setups may extend initial configuration time. |

⭐⭐⭐⭐⭐ Thomas Reed - Electrical Equipment Factory

"We've been using the Pro Model for six months now, and it’s transformed our production line. The ±0.02mm precision in edge folding has eliminated misalignment issues in high-voltage transformer coils. Setup was smooth thanks to the intuitive touchscreen interface, and we’ve seen a 28% increase in output since switching from our old semi-automatic system. The ATEX certification also gives us peace of mind operating in sensitive environments."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Medium-Scale Transformer Workshop

"As a smaller operation, we were hesitant about investing in full automation, but the Advanced Model struck the perfect balance. It handles 1.2–1.5mm insulation films flawlessly, and the customizable presets let us switch between job specs in under five minutes. We’re hitting 115 rolls/hour consistently, with zero downtime due to paper jams. The 5-year warranty was the deciding factor—this machine is built to last."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Industrial Automation Specialist

"Installed the Base Model in a pilot production cell for low-voltage transformers. While it doesn’t have AI-driven automation like the higher tiers, the fully automatic operation still reduced manual labor by 40%. The ISO 13849-1 compliance passed our safety audit with no issues. Only reason I’m not giving five stars: initial configuration took longer than expected due to lack of on-site training support. Once calibrated, though, performance has been rock-solid."Purchase Date: May 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Anita Patel - International Transformer Manufacturer

"We deployed three Pro Models across our facilities in Germany, India, and Mexico. Uniformity in coil quality is now consistent across continents. The robust build and triple safety certification (ISO, CE, ATEX) ensured regulatory compliance everywhere. What impressed me most? The 25% reduction in unplanned downtime—a claim that actually delivered. Maintenance logs show minimal wear even after seven months of 24/7 operation."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Marcus Johnson - Equipment Maintenance Lead

"Running the Advanced Model for five months in a high-utilization plant. Productivity gains are real—we’re averaging 142 coils/hour, just shy of the 150 max, likely due to material variance. The guarded spools and emergency stop system have already prevented two potential incidents. Only downside: the enclosed safety system makes routine roller inspections slightly more time-consuming. Still, the stainless steel rollers show no signs of wear—a big win over our previous alloy units."Purchase Date: April 2025 | Usage Period: 4 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Rebecca Liu - Senior Engineer, Power Systems Manufacturing Institute

"For transformer coil production, precision and repeatability are non-negotiable. This machine’s ±0.02mm folding accuracy and multi-thickness compatibility set a new benchmark. I recommend the Pro Model for any facility producing high-voltage transformers where insulation integrity directly impacts safety and performance."

James Carter - Automation Solutions Advisor

"After evaluating over 20 coil winding systems, this machine stands out for its true automation integration and scalable customization. The programmable interface reduces changeover time significantly, making it ideal for mixed-model production lines. The 5-year warranty reflects confidence in long-term reliability—a rare offering in this class."

Posted: 2 days ago

"The edge folding consistency is unmatched. No more rework due to misaligned insulation. Worth every penny for high-spec production."

Posted: 1 week ago

"Paid for itself in under seven months. Uptime is above 98%, and operator feedback on ease of use is excellent."

Posted: 3 weeks ago

"Perfect fit for our volume. Only suggestion: include more preset templates out of the box for common coil types."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.