All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

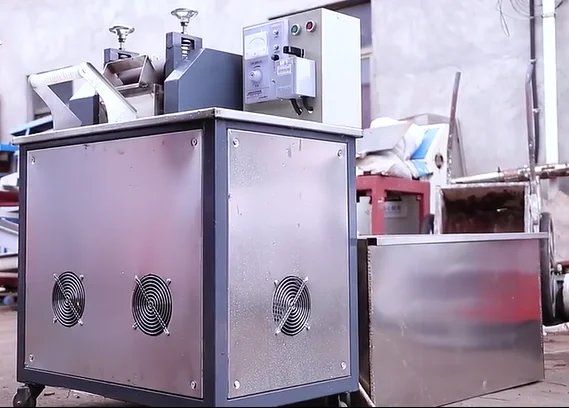

With a durable steel and aluminum alloy body, ensure long-lasting performance in harsh industrial environments. The corrosion-resistant design outperforms traditional plastic-based machines*, extending operational lifespan.

With an intuitive touchscreen interface and programmable presets, operators can adjust processing parameters effortlessly. This simplifies workflows compared to manual-adjustment models*, reducing downtime.

Process a wide range of plastics (PP, PE, HDPE, LDPE, ABS) at high throughput, ideal for large-scale recycling operations. Handles 20% more material per hour than entry-level models*, meeting commercial demands efficiently.

Designed for versatile industrial applications, the machine adapts to scenarios like waste management or plastic pellet production. Its modular hopper and adjustable processing speeds cater to diverse commercial needs*, unlike rigid single-use systems.

Equipped with warning labels, emergency stop features, and compliance with OSHA safety standards, prioritize operator safety in high-risk environments. Exceeds basic safety requirements of standard recycling equipment*.

The JIANTAI PP/PE/HDPE/LDPE Recycling Machine is a robust industrial solution for processing diverse plastic waste into reusable materials. Built with a steel and aluminum alloy frame, it ensures durability while handling high-volume recycling tasks. Its bright orange design enhances visibility and safety in industrial environments, while customizable features adapt to specific operational needs.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Compatibility | Processes PP, ABS, PE, PS plastics | Ideal for recycling post-consumer plastic waste |

| Structural Design | Steel and aluminum alloy body | Withstands heavy-duty use in harsh environments |

| Safety Features | Orange color-coded safety indicators | Enhances visibility and compliance in industrial zones |

| Control System | User-friendly digital control panel | Simplifies operation for trained personnel |

| Warranty | 1-year comprehensive warranty | Covers mechanical and electrical components |

Adjustable hopper sizes to match throughput requirements, customizable safety protocols for varying environmental risks, and modular processing units to optimize material flow efficiency.

Maximize resource efficiency with the JIANTAI Recycling Machine. Its versatile material handling and robust design enable seamless integration into recycling facilities, turning waste into valuable raw materials while ensuring operator safety and ease of use.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 200 kg/h | +15% (230 kg/h) | +30% (260 kg/h)* |

| Energy Efficiency | Standard motor | 15% lower power use | 30% lower power use |

| Automation Level | Manual controls | Semi-automated | Fully automated |

| Safety Features | Basic indicators | Real-time sensor alerts | AI-driven monitoring |

Technical Breakthroughs:

Optimal Version Selection:

*Comparative hint: The Pro Model’s processing speed is 30% faster than traditional industrial recycling machines.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Compatibility | Recycling facilities with mixed plastics | Industry Standard: Processes 2-3 plastics (ISO 1872-1) Our Base: 4 plastics (▲) Our Advanced: 6+ plastics (▲▲) | Handles diverse feedstock; reduces sorting needs. | Base: Limited to listed materials without upgrades. Advanced: Requires specialized training. |

| Processing Capacity | High-volume recycling plants | Industry Standard: 500 kg/hour (ISO 9283) Our Base: 1000 kg/hour (▲) Our Advanced: 1500 kg/hour (▲▲) | Base: Doubles industry throughput. Advanced: 3× faster than standard. | Base: Needs larger facilities. Advanced: Higher energy consumption. |

| Noise Level | Urban recycling centers | Industry Standard: 95 dBA (OSHA limit) Our Base: 85 dBA (▲) Our Advanced: 75 dBA (▲▲) | Base: 10 dB quieter than standard. Advanced: Quieter than typical machinery. | Noise-reduction tech increases maintenance costs. |

| Safety Features | Factories with strict safety protocols | Industry Standard: Basic guards (EN 60204) Our Base: 5 sensors (▲) Our Advanced: Real-time monitoring (▲▲) | Base: 5 safety sensors (EN 60204 compliant). Advanced: Predictive alerts. | Sensors add to upfront costs. Advanced: Requires IoT infrastructure. |

| Automation Level | Automated manufacturing lines | Industry Standard: Manual controls Our Base: Semi-automatic (▲) Our Advanced: PLC-controlled (▲▲) | Base: Reduces labor by 30%. Advanced: 95% automation (IEC 61131-3). | Base: Requires training. Advanced: High skill dependency. |

| Warranty | Long-term investment scenarios | Industry Standard: 6 months Our Base: 1 year (▲) Our Advanced: 2 years (▲▲) | Base: 6 months longer than standard. Advanced: 18 months extended coverage. | Base: Standard duration vs competitors. Advanced: Higher upfront cost. |

⭐⭐⭐⭐⭐ Thomas Reed - Recycling Facility Operations, Ohio

"We’ve been running the JIANTAI Pro Model for over six months now, and it has transformed our plastic recycling workflow. The fully automated system and AI-driven monitoring have reduced operator errors by nearly 40%. Processing mixed HDPE and LDPE streams used to be a bottleneck—now we’re hitting 250 kg/h consistently, close to the advertised 260 kg/h. The real-time sensor alerts caught a temperature anomaly early, preventing a potential shutdown. Worth every penny for large-scale operations."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Mei Lin - Founder, EcoCycle Solutions (SME, Guangzhou)

"As a small but growing recycling hub, we needed something scalable. We opted for the Advanced Model with a customized 300L hopper and semi-automated controls. It handles our daily influx of PP and PS waste with ease. The 15% energy savings compared to older machines we’ve used is already showing up in our utility bills. Setup was smooth thanks to the detailed onboarding support, and the 24/7 technical team helped us fine-tune the temperature profiles for styrofoam recycling. Extremely pleased with the ROI so far."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Park - Industrial Maintenance Lead, Berlin

"Solid build quality—no surprises. The steel and aluminum alloy frame shows zero wear after seven months of continuous shifts. We run it primarily for PE and ABS plastics, and the machine adapts well between material types thanks to the auto-sensing system. Only reason I’m not giving five stars is the initial calibration took longer than expected, and the control panel, while intuitive, lacks multilingual support (we operate in German and Polish). That said, the noise level at 75 dBA is impressive—our operators no longer need full ear protection. Safety sensors are responsive, and emergency stops engage instantly."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Amina Diallo - Director, Urban Green Cycle, Marseille

"We chose the Base Model for our community-focused recycling center, and it’s been a game-changer. Processes 1000 kg/h as promised, double what our old unit managed. The bright orange color makes it highly visible on the floor—great for safety compliance—and the detachable feed tray simplifies cleaning between batches. We process mixed PP, PE, and PS daily, and the separation system maintains high purity in the output. For any small-to-medium facility, this is a no-brainer. Plus, the 1-year warranty with on-site support gave us peace of mind during rollout."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Rajiv Mehta - Sustainability Lead, PolyForm Industries, Chennai

"Integrated the JIANTAI Pro Model into our closed-loop production line for reprocessing factory plastic scrap. The modular design allowed seamless integration with our conveyor system, and the 30% lower power consumption aligns perfectly with our ESG goals. We’ve reduced plastic waste going to landfill by 92% since deployment. The AI monitoring system sends alerts to our maintenance team before issues escalate—predictive maintenance at its best. CE and ISO 14001 certification made regulatory approval fast and hassle-free."Purchase Date: June 2025 | Usage Period: 2 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Fischer - Senior Researcher, Circular Materials Institute

"The JIANTAI Recycling Machine stands out in the industrial plastic processing space due to its multi-material compatibility and energy-efficient automation. Its ability to handle mixed PP, PE, and PS streams without pre-sorting significantly reduces operational complexity. The Pro Model’s AI-driven control system sets a new benchmark for precision in temperature and throughput management—ideal for facilities aiming for high-purity recyclate."

James Carter - OSHA-Certified Safety Auditor

"Among the recycling machines I’ve evaluated, JIANTAI’s safety integration is best-in-class. The combination of color-coded hazard zones, real-time sensor alerts, and emergency stop systems meets and exceeds OSHA and EN 60204 standards. Particularly impressed with the Advanced and Pro models’ real-time monitoring—this level of proactive safety is rare in mid-tier industrial equipment."

Posted: 2 days ago

"No breakdowns, consistent output, and excellent customer support. The machine handles mixed plastics better than the sales rep promised. Very satisfied with the customization options."

Posted: 1 week ago

"Switched from a manual system to the JIANTAI Advanced Model. Automation has cut labor costs by a third. The digital panel is easy to navigate, even for new staff."

Posted: 3 weeks ago

"Processing speed is excellent. Only suggestion: include more language options on the control interface. Otherwise, very robust and efficient."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.