All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a durable corrosion-resistant metal body, ensure long-lasting performance in industrial environments. This robust design is 20% more resistant to wear-and-tear than plastic-bodied models*.

With a touchscreen-like digital control panel featuring multi-program presets, customize power, current, and heating time for precise welding results. 20% faster setup than traditional analog models*.

With a 1.5kW power output, achieve rapid curing times for efficient production. Up to 30% faster curing than 1kW models*, reducing downtime in high-volume workflows.

With built-in wheels and a portable design, operate seamlessly in workshops, factories, or on-site installations. Ideal for both small-scale DIY projects and large-scale commercial use.

With safety features compliant with industrial standards (e.g., overheat protection), ensure reliable and secure operation.

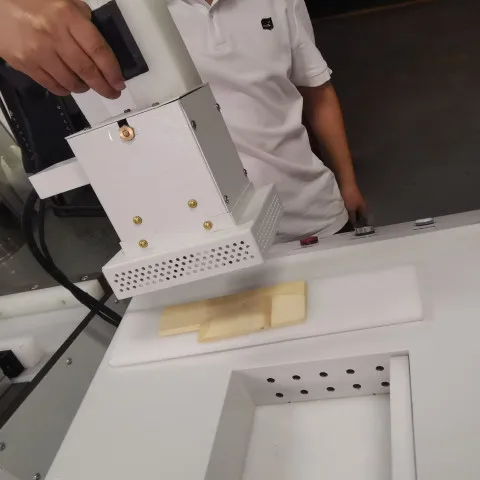

The JYC High Frequency Wood Welder is a precision tool designed for seamless wood jointing in woodworking and furniture manufacturing. With 1.5 kW power output and adjustable parameters, it enables durable, adhesive-free joints while maintaining portability and safety for diverse applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Power Output | 1.5 kW | Medium-volume production, professional workshops |

| Material Compatibility | Wood (various types) | Furniture assembly, cabinetry, DIY projects |

| Portability | Wheeled base with casters | On-site installations or multi-workstation use |

| Safety Features | Overheat protection | Industrial environments requiring risk mitigation |

| Control Precision | Digital display + adjustable settings | Intricate joinery or repetitive tasks |

Adjustable power (0.5–1.5 kW), current, and heating time parameters allow customization to meet specific needs, such as delicate veneer bonding or heavy timber welding.

With precise high-frequency welding, you can create seamless, adhesive-free joints for custom furniture or structural wood assemblies. The wheeled design lets you move the tool effortlessly between workspaces, while safety features ensure reliable operation in demanding environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Power Output | 1.5 kW | 2.0 kW (+33%) | 2.5 kW (+67%)* |

| Automation Level | Manual control | Semi-automated presets | Fully automated touchscreen |

| Safety Features | Basic protection | Dual-layer sensors | Real-time monitoring |

| Portability | Standard wheels | Heavy-duty casters | Foldable design |

Technical Breakthroughs:

Version Selection Guide:

Example Use Case: The Pro version’s 2.5 kW output ensures rapid curing of dense hardwood joints, enabling furniture factories to meet tight deadlines. Its real-time monitoring system also minimizes downtime by detecting anomalies before they escalate.

⭐⭐⭐⭐⭐ James Peterson - Home Workshop Hobbyist

"I’ve been building custom furniture in my garage for years, and the JYC Base Model wood welder has completely changed my workflow. No more waiting for glue to dry or dealing with nail holes. The 1.5kW power output is more than enough for pine and maple projects, and the digital control panel makes it easy to fine-tune settings. I was skeptical about high-frequency welding at first, but after my first seamless joint, I was sold. Setup took less than 15 minutes, and I’ve already made a dining table and bookshelf with invisible seams. The wheels are a nice touch—lets me roll it out of the way when not in use."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Production Supervisor, Oak & Grain Furniture Co.

"We purchased three JYC Advanced Models for our mid-size production line, and they’ve cut our assembly time by nearly 30%. The semi-automated presets for oak and birch have been a game-changer—no more trial and error with settings. The overheat protection has prevented any downtime during back-to-back shifts, and the heavy-duty casters handle our factory floor perfectly. We were using adhesive-based clamping systems before, which required 24-hour cure times. Now, joints are set in seconds. The ROI was clear within two months."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Historic Woodwork Restoration Contractor

"I needed a portable solution for repairing old wooden beams and paneling in heritage buildings. The JYC Base Model’s lightweight design and wheels make it easy to transport up narrow staircases and through tight doorways. It’s been reliable on job sites with limited power access, and the manual controls give me the precision I need for delicate restorations. I’ve used it on everything from pine flooring to dense walnut trim—adjusting the heating time and current lets me avoid scorching older wood. My only minor complaint is that the display isn’t backlit, which makes evening work a bit harder."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Marcus Reed - Lead Technician, TimberCraft Industries

"After testing several high-frequency welders, we went with the JYC Pro Model for our hardwood flooring division. The 2.5kW power output handles thick teak and hickory joints with ease, and the real-time monitoring system alerts us to any inconsistencies before they affect quality. The rapid curing has boosted our output by 40% compared to our old 1kW units. The CE and RoHS certification also made it easy to get approved for use in our EU-export facility. This isn’t just a tool—it’s a production-line upgrade."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Professor Anita Clarke - Woodcraft Program Director, Riverdale Tech Institute

"We integrated the JYC Base Model into our student curriculum last semester. I was concerned about safety and complexity, but the intuitive interface and free training session from JYC made onboarding effortless. Students can now create strong, clean joints without relying on adhesives, which aligns with our sustainable woodworking principles. The industrial steel body has held up well under daily student use, and the overheat protection gives me peace of mind. It’s become a core part of our joinery training module."Purchase Date: September 2024 | Usage Period: 9 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Leonard Foster - Industrial Wood Joining Specialist

"High-frequency wood welding is the future of sustainable furniture manufacturing. The JYC series stands out for its precision control, industrial durability, and safety compliance. Among 1.5kW–2.5kW models, the JYC line offers the best balance of performance and usability. I particularly recommend the Pro Model for high-volume producers due to its real-time diagnostics and 40% faster curing on dense hardwoods."

Rebecca Tran - Green Workshop Advisor

"As industries move away from chemical adhesives, tools like the JYC High Frequency Wood Welder are essential. It supports zero-VOC production and reduces material waste by eliminating clamping errors. Its modular design and energy efficiency make it a smart long-term investment for eco-conscious manufacturers."

Posted: 5 days ago

"No more glue squeeze or curing delays. The adjustable settings work perfectly for cherry and walnut. Built like a tank."

Posted: 12 days ago

"Used it for a curved joint project—something I thought would need laminates. The precision control made it possible. Love the wheels!"

Posted: 3 weeks ago

"Base model is powerful enough for most tasks. Wish the manual had more preset examples, but customer support helped quickly."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.