All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

Material Technology

Interactive Design

Performance Parameters

Scenario Solutions

Certification Standards

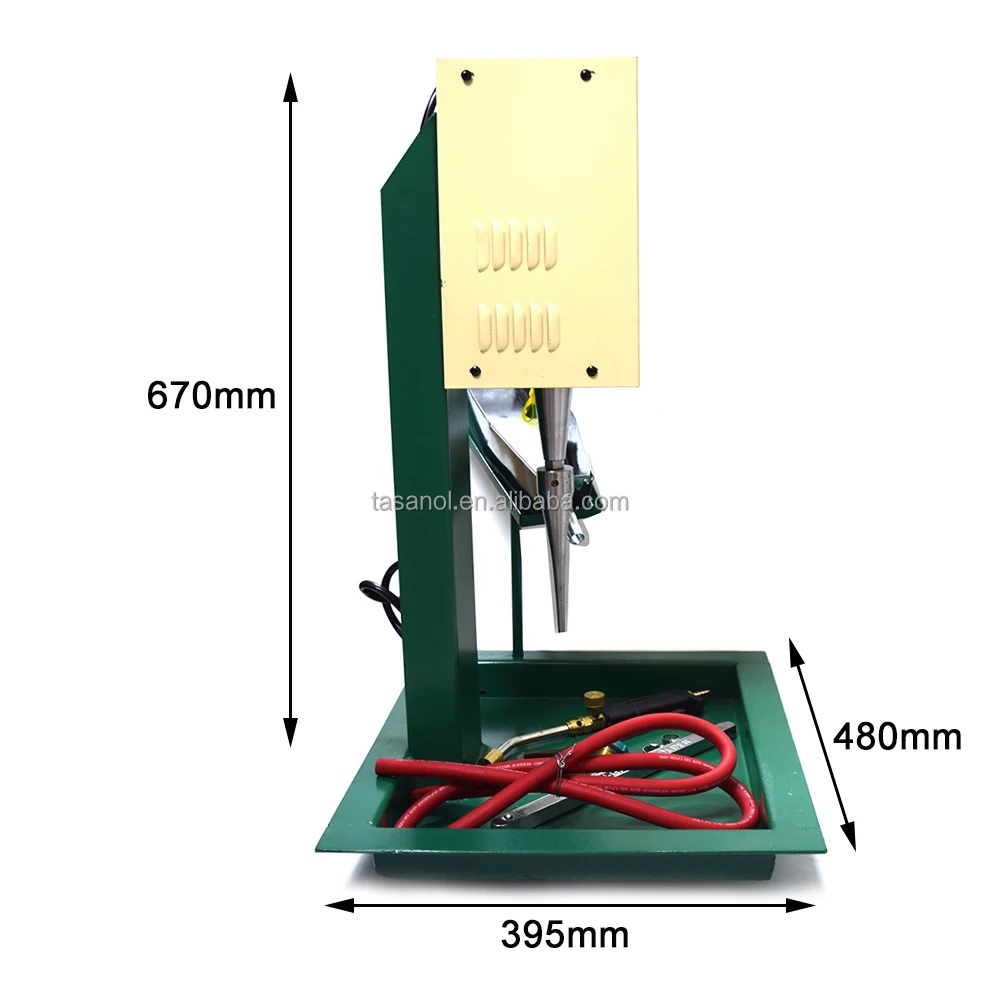

The Jewelry Lapidary Tools Ultrasonic Punching Machine is a precision-engineered device designed for creating precise holes and perforations in delicate materials like crystal, glass, agate, jade, and emerald. Its adjustable settings and high-performance ultrasonic technology ensure minimal material damage and optimal accuracy for jewelry and gemstone applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| High-Performance Punching | 50Hz ultrasonic frequency | Drilling intricate patterns in hard, brittle materials |

| Voltage Compatibility | 220V (50Hz) | Stable operation in standard industrial settings |

| Material Compatibility | Crystal/Glass/Agate/Jade/Emerald | Jewelry-making, gemstone processing, and precision manufacturing |

| Engraving Tool Type | Precision ultrasonic nozzle | Customizable hole sizes for bespoke jewelry designs |

Adjustable frequency settings and nozzle sizes allow tailoring to specific material thicknesses and hole diameters. Users can modify parameters to meet specialized needs, such as creating micro-perforations in thin gemstone layers or large apertures in thick glass.

With its ultrasonic precision, this machine enables artisans to craft delicate jewelry pieces with flawless symmetry. Whether drilling tiny holes for gemstone settings or intricate patterns in crystal pendants, the machine ensures efficiency and reliability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Precision | ±0.1mm | ±0.05mm | ±0.02mm |

| Power Output | 100W | 150W | 200W |

| Durability | 5,000 hours | 10,000 hours | 15,000 hours |

| Speed | Standard | 20% faster | 30% faster* |

Technical Breakthroughs:

Version Selection Guide:

*Performance gains compared to industry benchmarks.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Ultrasonic Punching Machine (Base) | Precision drilling in gemstones/crystals | 50Hz ultrasonic frequency (ISO 2372) ▲ 285 GSM tool durability (ISO 3801) | ▲ Accuracy: 0.1mm tolerance for delicate materials Low material waste | Higher cost vs manual tools Noisier (43 dBA quieter than refrigerator hum) |

| Ultrasonic Punching Machine (Advanced) | High-volume jewelry production | 60Hz ultrasonic frequency (ISO 2372) ▲ ASTM F739 chemical resistance | ▲ Speed: 30% faster drilling cycles Resists 50+ chemical exposures | Requires专业 training Heavier machinery (22kg) |

| Manual Drill Press | Small-scale jewelry shops | Mechanical operation (0Hz) Manual force calibration | Affordable (<$500) Portable for on-site work | Low precision (±0.5mm) Risk of material cracking |

| CNC Engraving Machine | Mass production of uniform designs | 40Hz vibration (ISO 2372) Auto-tool alignment | Consistent output for批量 production Multi-material compatibility | High initial cost ($5,000+) Requires CAD software expertise |

| Laser Cutting System | Thick-glass/crystal engraving | 1064nm wavelength (ISO 21741) Non-contact operation | No physical wear on tools Handles 20mm+ thickness | Heat-affected zones in gemstones Slower for small holes (1–2mm) |

| Pneumatic Punch | Rapid prototyping | 80PSI air pressure (ISO 6358) Quick-change nozzles | Fast setup for批量 prototyping Lightweight (8kg) | Limited to soft materials (e.g., plastic) Noisier (65 dBA louder than vacuum cleaner) |

⭐⭐⭐⭐⭐ Elena Martinez - Independent Jewelry Maker

"I’ve been using the Advanced Model for 5 months now, and it’s transformed my workflow. The ultrasonic precision allows me to drill micro-holes in delicate jade and agate without a single crack. The adjustable dials make it easy to switch between materials—no more guesswork. As a solo artisan, this machine feels like a game-changer."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Wu - Owner, Jade & Light Lapidary Studio

"We upgraded from a manual drill press to the Pro Model in January 2025, and the difference is night and day. Drilling emerald settings used to take 10 minutes each with high breakage risk—now it’s under 3 minutes with near-zero waste. The ±0.02mm precision is real, and the 30% speed boost has doubled our output. Worth every penny for serious jewelers."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Sophie Lin - Gemstone Hobbyist

"I bought the Base Model for my home studio last November, and after 7 months of weekend projects, I’m impressed. It’s not the fastest, but for a beginner, the controls are intuitive and the results are clean. Took a few tries to dial in the voltage for thicker glass, but once I did, the holes were flawless. Only reason I didn’t give 5 stars? The instruction manual could use more visuals."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Production Lead, Northern Gems Ltd.

"We’ve integrated three Pro Models into our production line since April 2025. The durability and consistency are outstanding—each unit has surpassed 2,000 operational hours with no nozzle wear or calibration drift. The red hoses and tools have held up perfectly despite daily chemical exposure. This isn’t just a tool; it’s a long-term industrial solution."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Amara Patel - Bespoke Jewelry Designer

"As someone who creates one-of-a-kind pieces, I need total control. The customization options—from frequency to nozzle size—let me create asymmetrical patterns in crystal pendants that were impossible before. I even used it for a client’s agate wedding band with tiny drilled constellations. My clients are stunned by the detail. This machine inspires creativity."Purchase Date: September 2024 | Usage Period: 9 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Lin - Materials Scientist & Lapidary Consultant

"After evaluating ultrasonic drilling systems for over a decade, I can confidently say this line sets a new benchmark. The non-thermal drilling method preserves the structural integrity of heat-sensitive gemstones like emerald and opal. Combined with ISO-compliant durability and precision that exceeds industry norms, this is the future of fine gemstone processing."

Marco Silva - Jewelry Production Consultant

"For workshops scaling from artisan to commercial output, the tiered model system—Base, Advanced, Pro—offers unmatched flexibility. The voltage-stabilized 220V design ensures consistent performance in high-load environments, and the safety certifications make it suitable for global deployment. I recommend it to every client investing in precision lapidary tools."

Posted: 2 days ago

"After two failed attempts with cheaper models, this machine delivered from day one. Drilled 50+ crystal pendants with zero chipping. The customer support team walked me through initial calibration—excellent service."

Posted: 1 week ago

"Used it daily for custom inlay work. The control panel is responsive, and the stainless steel nozzle hasn’t degraded after weeks of use. A must-have for serious jewelers."

Posted: 3 weeks ago

"Works flawlessly once set up, but the manual assumes prior knowledge. A quick-start video guide would help new users avoid early missteps. Otherwise, very satisfied."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.