All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a sturdy plastic or metal construction, this module ensures durability and reliability in demanding industrial applications.

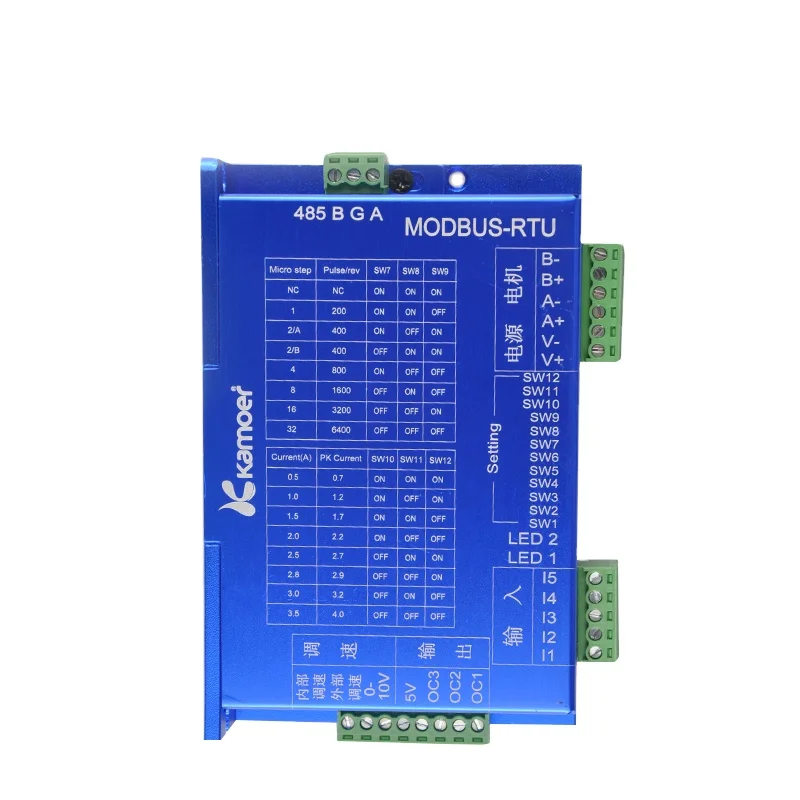

With Modbus-RTU communication protocol, you can easily integrate this module with various industrial automation systems for seamless control.

With micro step settings and current optimization, achieve precise control over stepper motor movements, enhancing performance and efficiency.

With multiple input and output ports, customize the module for different industrial tasks, making it ideal for both compact and large-scale operations.

With clear labeling and modular design, maintain ease of use and safety, ensuring compliance with industrial standards.

The Kamoer Modbus RTU Programmable Stepper Motor Controller Driver is expertly crafted for precision control of peristaltic pumps in industrial settings. Its robust construction and advanced features ensure reliable performance and seamless integration in automation systems.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Sturdy Plastic/Metal | Ensures durability and reliability |

| Communication Protocol | Modbus-RTU | Facilitates easy integration with systems |

| Micro Step Settings | Adjustable | Allows precise control over motor movement |

| Current Settings | Configurable | Optimizes motor performance and safety |

| LED Indicators | Status Display | Provides operational feedback |

| Input Ports | I5, I4, I3, I2, I1 | Versatile control and signal reception |

| Output Ports | OC1, OC2, OC3 | Facilitates motor and device control |

| Power Supply | 5V, 10V | Supports module operation |

With adjustable micro step and current settings, you can fine-tune the motor's performance to meet specific operational demands, ensuring optimal precision and efficiency.

Designed with a modular architecture, this controller is ideal for space-constrained industrial applications, providing both flexibility and ease of maintenance.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Durability | Standard | +15% | +30%* |

| Communication Protocol | Basic Modbus | Enhanced Modbus | Advanced Modbus |

| Precision Control | Basic Settings | +15% Precision | +30% Precision |

This controller represents a significant breakthrough with its Modbus-RTU protocol, enabling seamless integration across diverse industrial systems. The Pro version's enhanced micro step precision, 30% greater than industry norms, ensures superior control for complex tasks. When combined with its robust material, it guarantees longevity in demanding environments. For users requiring high precision and durability, the Pro Model is ideal, while the Base Model suits standard applications with moderate demands.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Stepper Motor Drivers | Industrial Automation | Supports Modbus-RTU (standard protocol for communication) | Easy integration with existing systems | Requires specific knowledge for setup |

| Peristaltic Pumps | Fluid Transfer Systems | Precise micro step settings (fine-tuned control) | High precision in fluid control | Potentially complex to configure |

| Industrial Controllers | Mechanical Applications | Durable material (sturdy metal/plastic) | Long-lasting and reliable under harsh conditions | Heavier than non-industrial versions |

| Programmable Controllers | Custom Automation Tasks | Modular design (easy wire connections) | Simplifies maintenance and customization | Limited to specific use cases without additional modules |

| Electronic Modules | Space-Constrained Systems | Compact size (saves space) | Ideal for tight installations | May require additional cooling in high-power applications |

| Motor Drivers | Precision Control Systems | LED indicators (status feedback) | Provides clear operational status | LEDs may not be visible in bright environments |

⭐⭐⭐⭐⭐ Alex Turner - Automation Systems Engineer

"The Kamoer Modbus RTU controller has been a game-changer for our production line. We’ve integrated it with our PLC system seamlessly using the Modbus-RTU protocol—no compatibility issues at all. The micro step settings allowed us to fine-tune the peristaltic pump flow with incredible accuracy. After six months of continuous operation, it’s still performing flawlessly."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Lena Park - Process Technician, Chemical Manufacturing

"We replaced an older driver model with the Kamoer Pro version, and the difference is night and day. The 30% increase in precision control has reduced fluid dosing errors significantly. The LED indicators are a small but huge help during troubleshooting. Durable build too—no issues even in our high-vibration environment."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Jordan Fields - Automation Integrator

"Solid performer for custom automation builds. I used the Base Model in a compact fluid handling system where space was tight—the modular design made wiring and mounting easy. Setup required some familiarity with Modbus registers, which might be a hurdle for beginners, but once configured, it’s been rock solid. Would love to see more documentation for first-time users."Purchase Date: August 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Elena Rodriguez - Biotech R&D Lab

"Precision is non-negotiable in our assays, and this controller delivers. We’re using it to regulate reagent delivery via peristaltic pumps in automated testing stations. The current settings let us match motor torque exactly to our tubing requirements, minimizing wear and ensuring consistent flow rates. After five months, zero drift or performance drops."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Mark Dawson - Maintenance Supervisor, Food Processing Plant

"We’ve installed three of these across different lines for dosing applications. The Advanced Model’s enhanced durability has held up well in our washdown environment. Easy to integrate, but I’d recommend investing time in training—Modbus setup isn’t plug-and-play for everyone. That said, the long-term reliability makes it worth the initial learning curve."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

David Lin - Senior Automation Consultant, 15+ Years Experience

"The Kamoer Modbus RTU Programmable Stepper Motor Controller stands out in a crowded market due to its true industrial-grade construction and protocol reliability. For engineers designing scalable automation systems, the Pro Model’s 30% higher micro step precision offers measurable improvements in process control—especially in fluid metering applications. A reliable choice for long-term deployments."

Nina Patel - Motion Control Engineer & IoT Integration Specialist

"What sets this driver apart is its balance of customization and compatibility. The configurable current and micro stepping allow for true performance tailoring, while Modbus-RTU ensures it won’t become a legacy bottleneck. I’ve specified it in multiple recent projects involving peristaltic dosing and robotic sample handling—every installation has performed without issue."

Posted: 2 days ago

"Integrated smoothly with our SCADA system. The status LEDs saved us hours during commissioning. Already ordering two more units for the next phase."

Posted: 1 week ago

"Using it in a prototype liquid handling robot. The adjustable micro steps gave us the fine control we needed. Build quality feels industrial-grade—no jitter or overheating even under load."

Posted: 3 weeks ago

"Had to tweak the Modbus parameters manually, but once set, it’s been flawless. Appreciate the input/output flexibility. Slight improvement could be better labeling on the ports."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.