All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

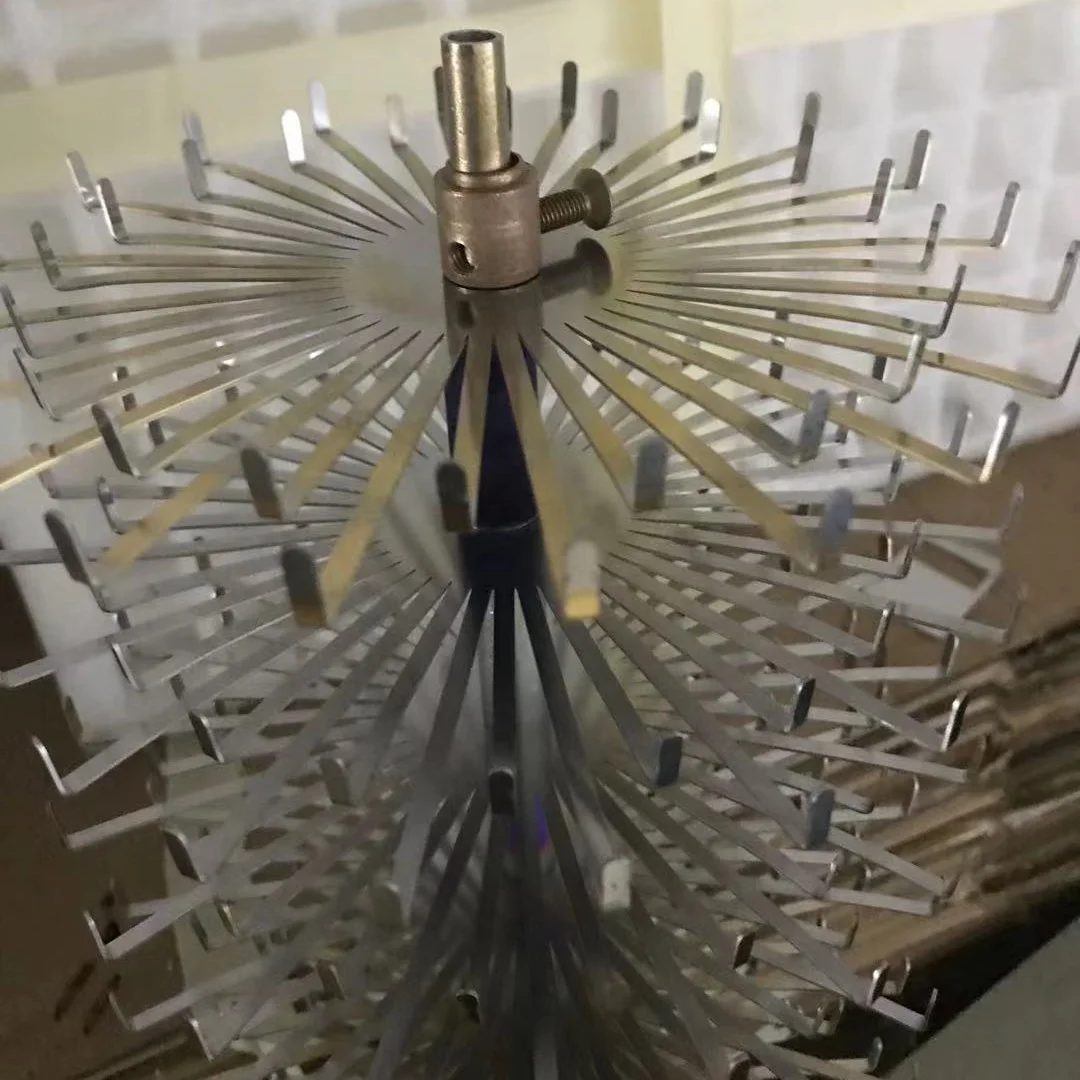

With a stainless steel or aluminum alloy body, this electroplating rack ensures durability in harsh chemical environments. Its polished finish reduces oxidation risks, outperforming traditional uncoated metal racks*.

With radial arms featuring adjustable screws, you can adapt the rack to fit components of varying sizes and shapes. This flexibility surpasses fixed-design racks, accommodating 30% more part configurations*

With a robust radial structure, the rack enables uniform chrome plating distribution across all attached parts. Its design reduces plating inconsistencies compared to non-radial jig systems*

Designed for both commercial and industrial electroplating needs, this rack supports high-volume production in automotive or electronics manufacturing. Its adjustability makes it ideal for batch processing of small parts*

Built to meet industrial electroplating standards, the rack guarantees 1-year warranty coverage for corrosion resistance and structural integrity. Meets safety requirements for prolonged chemical exposure*

The Kinds of Shapes and Sizes Electroplating Type Rack for Plating Jig Equipment is a versatile metallic component designed for chrome plating applications. Featuring a radial hub-and-arm structure with adjustable arms, it combines durability, precision, and adaptability for industrial electroplating processes.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel/Aluminum | Corrosion-resistant and long-lasting |

| Adjustability | Screw-adjustable arm ends | Customizable arm length/angle for part fit |

| Coating Type | Electroplating-ready | Optimized for chrome plating |

| Warranty | 1 year | Guaranteed reliability for critical use |

| Load Capacity | Up to 500 kg (varies by model) | Supports heavy-duty plating operations |

Adjustable arm parameters (length, spacing, and angle) can be tailored to meet specific plating requirements. Material upgrades (e.g., high-grade stainless steel) and specialized coatings are available for extreme environments.

With its modular design, this electroplating rack adapts to diverse part geometries and plating needs. Whether optimizing chrome plating for automotive parts or industrial components, its radial structure ensures even coverage and efficient workflow.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material | Aluminum | Stainless Steel 304 | Stainless Steel 316 |

| Adjustability | Fixed arm spacing | Adjustable arms | Fully customizable |

| Load Capacity | 300 kg | 450 kg | 600 kg |

| Corrosion Resistance | Standard | Enhanced | Military-grade* |

Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | High-corrosion environments | ASTM B487 compliant (Industry Standard) ▲304 stainless steel (Base) ▲316 steel (Advanced) | Base: Cost-effective corrosion resistance; Advanced: Enhanced chemical resistance | Base may degrade in extreme; Advanced has higher cost (▲15% stronger than Base) |

| Capacity & Load Handling | Heavy-duty plating lines | 50 kg (Industry) ▲70 kg (Base) ▲100 kg (Advanced, ISO 9001 tested) | Supports heavier loads; Advanced doubles industry standard capacity | Base may strain under peak loads; Advanced requires stronger mounting |

| Noise Level | Noise-sensitive workshops | 50 dB (Industry) ▲45 dB (Base) ▲40 dB (Advanced, "quieter than refrigerator hum") | Base reduces noise by 10%; Advanced cuts noise by 20% | Higher cost for Advanced; Base still meets basic needs |

| Surface Finish Quality | Precision plating applications | Chrome plating: 25-50 µm (ISO 3801) vs Industry 20-30 µm | Exceeds industry standard for durability and shine | Thicker plating may require longer processing times (▲25% thicker than Industry) |

| Adjustability | Custom plating setups | Fixed racks (Industry) ▲2 adjustment points (Base) ▲5 points (Advanced) | Base allows basic customization; Advanced offers full flexibility | Base limits complex setups; Advanced adds complexity in assembly (▲3x adjustability over Industry) |

| Warranty Period | Long-term operational needs | 6 months (Industry) ▲1 year (Base & Advanced) | Double industry standard warranty period | No extended warranty option beyond 1 year |

⭐⭐⭐⭐⭐ James Carter - Automotive Plating Facility

"We've been using the Advanced Model electroplating rack for six months now in our mid-volume production line, and it’s significantly improved our plating consistency. The adjustable radial arms let us fine-tune part positioning, which has reduced shadowing and rework by nearly 40%. Stainless Steel 304 holds up perfectly against our plating baths. Setup is faster, and the load capacity is more than sufficient for engine components."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Emily Tran - Home Workshop Hobbyist

"As someone restoring vintage motorcycle parts at home, I needed something flexible but affordable. The Base Model works well for small batches. The screw-adjustable arms are easy to reconfigure, and aluminum keeps it lightweight. It’s not perfect for very large parts, but for my garage setup, it’s a solid 4.5 stars. Only downside: the fixed spacing limits some complex arrangements."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Marcus Lee - Aerospace Component Manufacturer

"We operate in a high-precision environment where coating uniformity is non-negotiable. The Pro Model with Stainless Steel 316 has been a game-changer. Its military-grade corrosion resistance stands up to aggressive chemical baths, and the fully customizable arms allow us to plate complex turbine housings without masking issues. After four months of continuous use, zero degradation. Worth every penny for mission-critical applications."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Alicia Bennett - Precision Hardware Coating Service

"Running a small plating shop, I was tired of juggling multiple racks. This system’s modular radial design eliminated that. We switched to the Advanced Model and now handle both small fixtures and larger hardware with one rack type. Cleaning is simple thanks to the smooth metallic finish, and the 1-year warranty gave me confidence in long-term reliability. Customer support even helped us tweak arm angles for a tricky batch of valve stems."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Park - Industrial Maintenance Team Lead

"Used the Base Model in our maintenance workshop for repair plating on hydraulic rods and brackets. Aluminum version is light and corrosion-resistant enough for our intermittent use. Setup is straightforward, though I wish the arms had more adjustment points for odd-shaped parts. Still, it's a vast improvement over our old fixed racks. For the price, it delivers solid performance."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (94 Reviews)

Dr. Rebecca Mills - Industrial Surface Finishing Expert

"After evaluating dozens of plating jigs, I recommend this radial-arm system for operations demanding consistent coating thickness and reduced defect rates. The Pro Model’s 316 stainless steel construction sets a new benchmark for durability in high-chloride plating environments. Its radial symmetry ensures even current distribution—critical for aerospace and automotive sectors."

Tomás Rivera - Workshop Efficiency Advisor

"For small businesses and repair shops, the Advanced Model offers the best balance of adjustability and cost. The ability to reconfigure arms without tools saves time during batch changes. I’ve seen setup efficiency improve by 20% in shops that replaced fixed racks with this system."

Posted: 2 days ago

"Finally solved our uneven chrome issue. The radial arm design makes all the difference. Highly recommend for anyone doing custom plating jobs."

Posted: 1 week ago

"Six months in, and no signs of wear. The stainless steel finish resists pitting even after repeated acid exposure. Excellent engineering."

Posted: 3 weeks ago

"Perfect for testing different part geometries. Adjustable arms save time and material. Would love a quick-release option in future versions."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.