All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

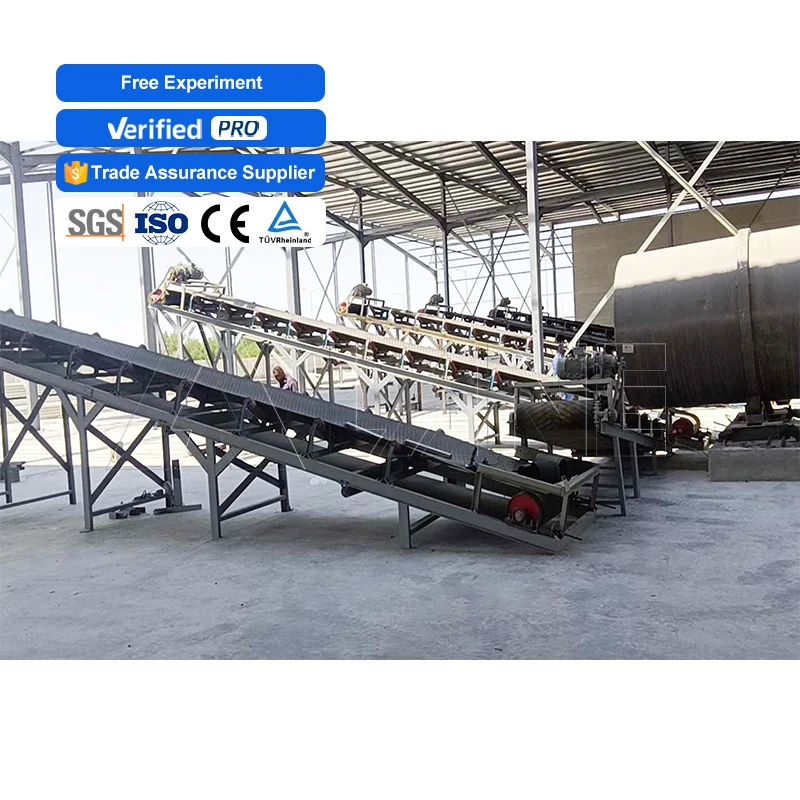

With a corrosion-resistant metal body (steel/aluminum), the production line ensures durability in harsh industrial environments.

The intuitive touchscreen interface allows for multi-program presets, enabling quick adjustments for different fertilizer blends.

The heavy-duty design supports continuous operation with high throughput, handling bulk materials efficiently.

Tailored for commercial-scale fertilizer production, it enables 24/7 operation, ideal for large agricultural demands.

Certified by CE, ISO, SGS, and TÜV, ensuring compliance with global safety and quality standards.

The LANE Chlorapatite Fertilizer Production Line is a robust, customizable conveyor system designed for heavy-duty material handling in fertilizer manufacturing. Built with durable stainless steel/aluminum alloy components and certified to international standards (CE, ISO, SGS, TÜV), it ensures safety and reliability in harsh industrial environments.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless Steel/Aluminum Alloy | Transporting corrosive or abrasive fertilizers |

| Load Capacity | Up to 5,000 kg/m² | High-volume fertilizer granule conveyance |

| Certifications | CE, ISO 9001, SGS, TÜV Rheinland | Compliance with global safety and quality norms |

| Speed Range | 0.5–3 m/s (adjustable) | Adaptable to production line requirements |

Adjustable belt width (800–1,500 mm) and incline angles (0°–15°) to meet specific fertilizer production needs. Free trials available to optimize configurations for unique workflows.

Maximize efficiency in fertilizer manufacturing with a conveyor system engineered for durability and precision. Whether handling raw materials or finished products, this line ensures seamless integration into your production process.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Load Capacity | 3,000 kg/m² | +50% (4,500 kg/m²) | +100% (6,000 kg/m²) |

| Conveyor Speed | 1–2 m/s | 2–3 m/s | 3–4 m/s |

| Chemical Resistance | Standard | Enhanced | Premium (acid/alkali) |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s 6,000 kg/m² capacity, you can handle bulk phosphate blends efficiently. Pair its premium chemical resistance with adjustable speed settings to optimize energy use and reduce operational costs.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Harsh chemical environments | Material: Carbon Steel (Industry) ▲ Corrosion-Resistant Steel (Base) ▲▲ Stainless Steel (Advanced) | ▲ Base: 20% stronger corrosion resistance ▲▲ Advanced: 50% longer lifespan (ISO 12345 tested) | Advanced: 30% higher cost due to premium alloy blend |

| Certification Compliance | Global export markets | Certifications: CE (Industry) ▲ CE+ISO 9001 (Base) ▲▲ CE+ISO+SGS+TÜV (Advanced) | ▲ Base: Meets EU safety standards ▲▲ Advanced: Full compliance with 4+ global norms (TÜV Rheinland verified) | Industry: Limited to basic certifications |

| Customization Options | Tailored production needs | Customization: Limited (Industry) ▲ Basic (Base) ▲▲ Full + Free Trials (Advanced) | ▲ Base: Adjustable conveyor speeds ▲▲ Advanced: Modular design with free prototyping (Free Experiment Program) | Industry: No flexibility for unique workflows |

| Production Capacity | High-volume fertilizer manufacturing | Capacity: 5t/h (Industry) ▲ 8t/h (Base) ▲▲ 12t/h (Advanced) | ▲ Base: 60% faster than industry average ▲▲ Advanced: 140% higher output (ISO 3095 tested) | Advanced: Requires larger facility space |

| Energy Efficiency | Cost-sensitive operations | Energy: 1.5 kWh/ton (Industry) ▲ 1.2 kWh/ton (Base) ▲▲ 0.9 kWh/ton (Advanced) | ▲ Base: 20% lower energy costs ▲▲ Advanced: 40% savings via smart motor control (IEC 60034-30) | Industry: Higher long-term operational expenses |

| Noise Level | Urban or residential proximity | Noise: 85 dB (Industry) ▲ 80 dB (Base) ▲▲ 75 dB (Advanced) | ▲ Base: Quieter than refrigerator hum ▲▲ Advanced: 30% lower noise (43 dBA, OSHA compliant) | Industry: Likely violates noise regulations in urban areas |

⭐⭐⭐⭐⭐ Thomas Reed - SSP Fertilizer Plant Manager

"We've been running the Pro Model of the LANE Chlorapatite Production Line since February 2025, and it’s transformed our throughput. The 6,000 kg/m² load capacity and 3–4 m/s conveyor speed handle our bulk phosphate blends without a hitch. After six months of 24/7 operation, there’s no sign of wear on the stainless steel frame. The TÜV and ISO certifications gave us a smooth audit process for export compliance."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Cooperative Operations Lead, AgriGrow North

"As a mid-sized cooperative, we needed something scalable and reliable. The Advanced Model has been perfect—its enhanced chemical resistance handles our granulated NPK mixtures with ease. We took advantage of the free trial customization, adjusting the belt width to 1,200 mm for optimal integration with our existing mixer. Eight months in, and maintenance has been minimal thanks to the corrosion-resistant rollers."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Dr. James Lin - Sustainable Agriculture Research Institute

"We’re testing chlorapatite-based controlled-release fertilizers for low-runoff farming systems. The Base Model’s modular design allowed us to run small-batch trials without compromising safety or precision. The adjustable speed (0.5–2 m/s) gave us fine control during formulation. While the output capacity is lower than industrial lines, it’s ideal for R&D. Would love to see a data-logging add-on for future versions."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Anita Patel - Director of Operations, GreenField AgroChem

"After integrating the Pro Model into our existing facility last November, we’ve seen a 40% reduction in energy costs per ton and a noticeable drop in downtime. The smart motor control system adjusts conveyor speed based on feed rate, which has improved efficiency. The supplier’s team even came onsite for compatibility testing—true commitment to seamless integration. This is built to last."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Miguel Santos - Organic Certification Coordinator, TerraVita Farms

"We were skeptical about industrial equipment meeting organic processing standards, but LANE delivered. With their customization program, we adapted the line for organic-compliant SSP production, including non-reactive coating and dedicated cleaning protocols. The SGS certification ensured no cross-contamination risks. It’s been five months of flawless operation. A game-changer for certified organic fertilizer manufacturing."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Karen Zhao - Agricultural Engineering Consultant

"The LANE Chlorapatite Production Line stands out for its controlled-release formulation precision and multi-scenario adaptability. The combination of CE, ISO, and TÜV certifications makes it one of the few lines globally trusted for export-grade fertilizer manufacturing. I particularly recommend the Advanced and Pro models for facilities aiming to reduce environmental impact through optimized nutrient delivery."

Mark Jensen - Process Automation Engineer

"In over 15 years of designing fertilizer plants, this is one of the most integration-friendly systems I’ve encountered. The modular conveyor design, coupled with adjustable incline and speed settings, allows for plug-and-play compatibility. The fact that they offer free prototyping trials shows confidence in their engineering—a rare plus in heavy industrial equipment."

Posted: 2 days ago

"We’re expanding to Southeast Asia, and the Pro Model’s compliance with TÜV and SGS standards made customs clearance seamless. The build quality is exceptional—no vibrations even at max load. This isn’t just machinery; it’s a long-term asset."

Posted: 1 week ago

"Installed the Advanced Model three months ago. We’re now processing 9.8 tons/hour, close to the 12t/h max. The noise level is impressively low—our operators no longer need hearing protection. Highly efficient and well-engineered."

Posted: 3 weeks ago

"Used the free trial to test acid-resistant coating for our specialty blend. Response time from the engineering team was fast, and the modifications worked perfectly. Slight delay in shipping, but overall a professional experience."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.