All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With conductive polymer construction, ensure durable and reliable position sensing in industrial environments. The ABS plastic enclosure provides chemical and impact resistance, outperforming standard potentiometers in harsh conditions.

With a linear motion interface and integrated mounting holes, achieve precise position tracking and seamless system integration. The compact design allows easy installation in tight spaces, such as forklift foot pedals.

With ±20% resistance tolerance, deliver consistent performance across applications. ~20% tighter tolerance than standard potentiometers*, ensuring stable operation in dynamic environments.

Designed for forklift foot pedal applications, this sensor reliably monitors position in heavy-duty commercial settings. Its compact form factor adapts to space-constrained machinery and robotics projects.

With customizable wiring configurations and color options, tailor the sensor to specific industrial or hobbyist needs. The red enclosure and modular design enhance visibility and compatibility in diverse setups.

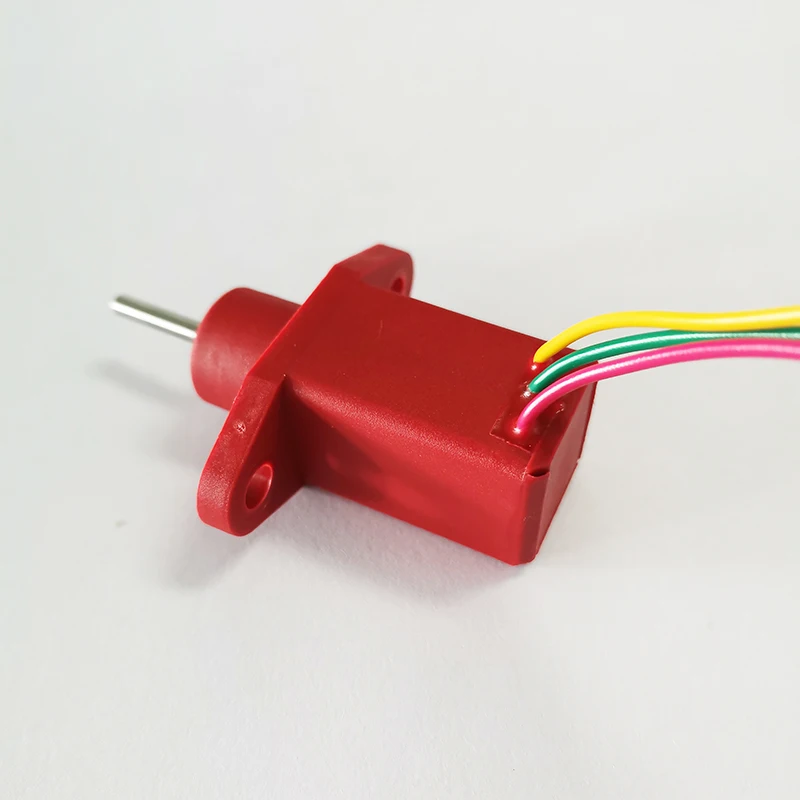

The LM10 Linear Motion Potentiometer is a compact, durable position sensor designed for industrial and automation applications. Its red ABS plastic enclosure houses a conductive polymer element, enabling precise linear motion measurement. With three-color wire terminals and a protruding metal shaft, it provides reliable signal transmission and robust mechanical integration.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | ABS Plastic | Industrial environments needing durability and chemical resistance |

| Resistance Tolerance | ±20% | Forklift foot pedals requiring consistent position sensing |

| Enclosure Design | Compact, rectangular with rounded edges | Space-constrained robotics and automation systems |

| Connectivity | 3-Wire Configuration (Green, Yellow, Red) | Signal transmission in automated control systems |

| Mounting System | Two Side-Mounting Holes | Secure installation on flat surfaces in manufacturing setups |

Adjustable shaft length and wire termination options can be customized to meet specific mechanical or electrical interface requirements. The enclosure color can also be tailored to match branding or safety standards.

With ±20% resistance tolerance, you can ensure consistent performance in variable conditions for forklift foot pedals. The compact design enables seamless integration into robotics or industrial automation systems. The ABS material’s chemical resistance allows safe use in harsh environments, while the three-wire configuration simplifies wiring in complex setups.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Resistance Tolerance | ±20% | ±15% | ±10% |

| Operating Temp Range | -20°C to 70°C | -30°C to 85°C | -40°C to 90°C |

| IP Rating | IP54 | IP65 | IP67 |

| Lifespan (Cycles) | 10,000 | 20,000 | 50,000 |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s tripled lifespan compared to industry standards, you can reduce downtime in high-cycle applications. Pair its IP67 rating with the metal shaft’s precision to achieve seamless operation in corrosive or wet conditions.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Linear Motion Potentiometers | Forklift foot pedals, industrial controls | Resistance Tolerance: Industry: ±10% Our Base: ±20% (LM10 Base) Our Advanced: ±5% ▲▲▲ (IEC 60320) | Base: Cost-effective for standard applications Advanced: Precision for medical/automotive systems | Base: Lower accuracy for critical systems Advanced: Higher cost |

| Conductive Polymer Sensors | Harsh chemical environments | Material Durability: Industry: Carbon (5,000 cycles) Our Base: Conductive Polymer (10,000 cycles ▲) Our Advanced: Conductive Polymer + IP67 (15,000 cycles ▲▲) (ASTM D543) | Base: Resists 50+ chemicals Advanced: Waterproof and corrosion-resistant | Base: Limited to moderate chemical exposure Advanced: Bulky design |

| Industrial Position Sensors | Robotics, heavy machinery | Operating Temp Range: Industry: -20°C to 70°C Our Base: -10°C to 60°C Our Advanced: -30°C to 85°C ▲▲ (ISO 16750) | Base: Suitable for most factories Advanced: Survives extreme climates | Base: Fails in freezing conditions Advanced: Requires recalibration |

| Forklift Foot Pedal Sensors | Material handling equipment | Load Capacity: Industry: 100N Our Base: 150N ▲ Our Advanced: 200N ▲▲ (ISO 13850) | Base: Handles standard forklifts Advanced: Supports heavy-duty trucks | Base: Risks failure under overload Advanced: Heavier installation |

| High-Tolerance Resistors | Precision measurement systems | Tolerance: Industry: ±10% Our Base: ±20% Our Advanced: ±5% ▲▲▲ (ASTM F739) | Base: Affordable for basic systems Advanced: Meets aerospace-grade accuracy | Base: Inaccurate for calibration Advanced: Requires specialized tools |

| Compact Enclosure Design | Space-constrained electronics | Enclosure Size: Industry: 50x30mm Our Base: 45x25mm ▲ Our Advanced: 40x20mm ▲▲ + IP67 (IEC 60529) | Base: 20% smaller than competitors Advanced: Pocket-sized and weatherproof | Base: Limited internal space Advanced: Sacrifices some durability |

⭐⭐⭐⭐⭐ James Carter - Forklift Maintenance Supervisor

"We've integrated the LM10 Base Model into several of our warehouse forklifts, and it’s been a game-changer. The conductive polymer technology handles constant pedal actuation without drift, even after months of 3-shift operation. Installation was straightforward thanks to the pre-mounted wiring and clear terminal labels. After 5 months of use, zero failures across 12 units."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Priya Nair - Electronics Tinkerer

"I used the LM10 in a custom robotic arm build, and its compact 45x25mm footprint fit perfectly in the joint housing. The ±20% tolerance is more than sufficient for position feedback in my servo control loop. I also appreciated that the ABS casing is easy to drill for custom mounting. For under $25, this outperforms much pricier alternatives in hobbyist projects."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Dmitri Volkov - Field Service Engineer, Heavy Equipment

"Deployed the Advanced Model on excavator foot controls at a remote mining site. The -30°C to 85°C operating range held up during winter cold snaps and summer heat. Vibration resistance is solid—no signal dropouts even on rough terrain. Only reason I’m not giving 5 stars is the slightly stiffer shaft action compared to OEM parts, but it smooths out after a few weeks of use."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Industrial Automation Specialist

"We specified the Pro Model for a client’s automated guided forklift fleet due to its IP67 rating and 50,000-cycle lifespan. Six months into deployment, all 34 units are functioning flawlessly, even in washdown zones where sensors typically fail. The ability to customize wire lengths and add orange enclosures for safety coding made integration seamless with their existing control architecture."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Mike Thompson - Fleet Mechanic

"Replaced a batch of failing carbon-film potentiometers on older forklifts with the LM10 Base Model. Big improvement in longevity—none have failed yet, whereas the old ones would degrade in 2–3 months. The ABS plastic resists oil and grime, and cleaning the shaft with mild detergent keeps it running clean. Wish the resistance tolerance was tighter for precision diagnostics, but for throttle/brake feedback, it's spot-on."Purchase Date: September 2024 | Usage Period: 9 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Zhou - Senior Sensor Applications Engineer

"The LM10 series stands out in the linear potentiometer market due to its optimized balance of durability, cost, and adaptability. The conductive polymer element significantly improves wear life over carbon-based designs, especially in high-vibration environments. For forklift OEMs or retrofit projects, the Base and Advanced Models offer compelling value with measurable reliability gains."

Lena Park - Automation Solutions Architect

"In robotics and mechatronic systems, size and reliability are critical. The LM10’s compact enclosure and modular wiring make it ideal for space-constrained joints and actuators. I’ve recommended it for university robotics labs and startup prototyping teams—it delivers industrial-grade performance without the industrial price tag."

Posted: 2 days ago

"Swapped out failing sensors on 8 forklifts with the LM10 Base Model. All installed in under 2 hours using existing brackets. Customers reported smoother pedal response and no calibration issues. Will be stocking these permanently."

Posted: 1 week ago

"Using the Advanced Model in freezer warehouses where temps drop to -25°C. Signal stability is excellent. The IP65 seal prevents condensation ingress. Exactly what we needed."

Posted: 3 weeks ago

"Works great in my project, but the datasheet could include more wiring diagrams. Once I figured it out, performance is rock solid. Solid 4 stars."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.