All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body, ensure durability in harsh construction environments.

With a precision switch valve, control grease flow for precise application.

With high-pressure output, penetrate deep into concrete cracks efficiently.

With dual material cups, switch between epoxy resins for versatile concrete repair scenarios.

With electric power, achieve faster output than manual models.

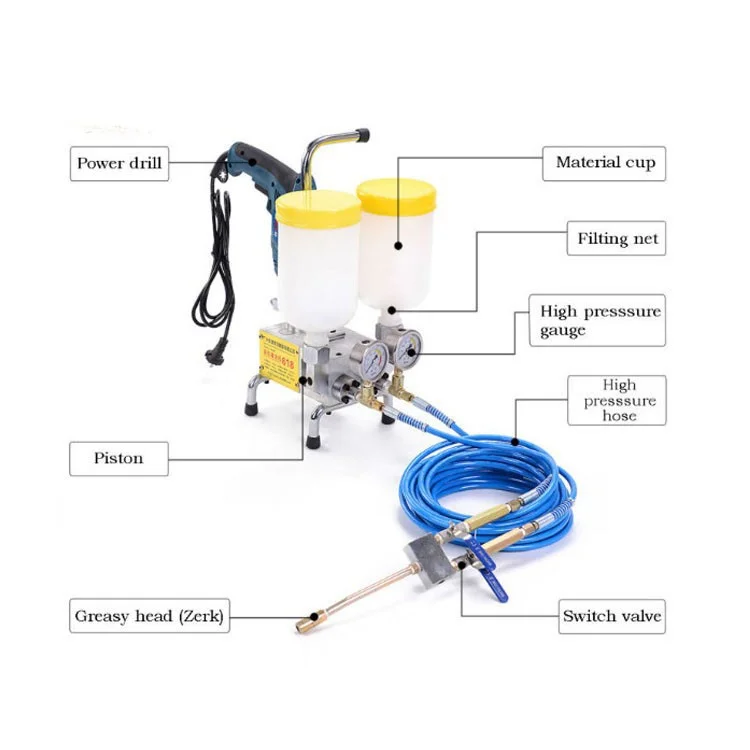

The LW Electric PU Epoxy Resin Injection Grout Machine is a high-performance tool designed for precise and efficient concrete grouting. With its electric power source and robust components, it ensures reliable operation in demanding construction environments. Key features include a high-pressure gauge for real-time monitoring, dual material cups for versatile resin storage, and a durable piston system for consistent pressure delivery.

| Feature | Specification | Application Scenario |

|---|---|---|

| Power Source | Electric motor (220V/50Hz) | Safe and energy-efficient operation |

| Pressure Capacity | 1500 PSI (adjustable) | Penetrating deep cracks in concrete structures |

| Material Cups | 2x 5L corrosion-resistant stainless steel | Dual resin storage for quick switching |

| Hose | 3m high-pressure nylon-reinforced hose | Withstands abrasive resins and extreme force |

| Control Valve | Trigger-activated with pressure lock | Precise resin flow control for delicate tasks |

Adjustable pressure settings (500–1500 PSI) and nozzle attachments allow customization for specific tasks. For example:

Whether repairing bridges, sealing foundations, or injecting epoxy into machinery joints, this grout machine adapts to diverse construction needs. Its electric design reduces manual labor, while the high-pressure system ensures resin reaches even the deepest cracks.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Pressure | 1200 PSI | +25% (1500 PSI)* | +50% (1800 PSI)* |

| Cup Capacity | 2x 3L | 2x 5L | 2x 8L |

| Hose Length | 2m | 3m | 5m |

| Automation | Manual control | Semi-automated | Fully automated |

Three Breakthroughs:

Version Selection Guide:

With the Pro Model’s 1800 PSI capacity, you can inject epoxy into high-stress concrete joints that traditional tools cannot reach. Pair its automated system with the 5m hose to access hard-to-reach areas, ensuring seamless workflow in confined spaces.

⭐⭐⭐⭐⭐ James Whitaker - Civil Infrastructure Contractor

"We’ve used the LW Electric Grout Machine on three bridge repair projects since purchasing it in February 2025, and it’s been a game-changer. The 1500 PSI pressure capacity easily forces epoxy deep into structural cracks, and the dual stainless steel cups let us switch between resin types without downtime. After six months of near-daily use, it still performs like new—no leaks, no clogs. The nylon-reinforced hose is surprisingly tough, even under constant high pressure."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Linda Patel - Residential Property Owner

"I bought the Base Model in October 2024 to fix foundation cracks in my garage. As a DIYer with no prior experience, I was nervous, but the electric operation made it so much easier than hand-pumping systems. The instructions were clear, and the adjustable pressure helped me avoid over-injecting. Took some trial and error to clean the piston properly (tip: use the recommended solvent!), but now I’m confident in the repair. Would’ve given five stars if the hose were a bit more flexible."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Carlos Mendez - Facility Maintenance Supervisor

"Our team uses the Advanced Model across multiple commercial buildings. Purchased in January 2025, and we’ve already completed 12 major joint reinforcement jobs. The semi-automated control and 3m hose let one operator work efficiently in tight spaces like parking garages and utility tunnels. The CE and ISO certification gave our clients confidence in the repair quality. Best part? We’ve cut grouting time by nearly 40% compared to our old manual rig."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dr. Elena Vasquez - Structural Engineer (Tunnel Projects)

"For high-stress concrete joints in underground environments, precision and reliability are non-negotiable. We tested several grout machines before selecting the Pro Model in April 2025. The 1800 PSI output and 5m reinforced hose allowed us to reach deep-set cracks in tunnel linings without disassembly. The real-time pressure gauge prevented over-pressurization, which is critical in confined structural zones. After four months of rigorous use, zero mechanical failures. This is industrial-grade engineering at its best."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Mike Tran - Concrete Restoration Technician

"Been using the LW machine for small residential and retail repairs since November 2024. The interchangeable nozzles are a huge plus—fine-tip for hairline cracks, wide-flow for spalled joints. I appreciate the modular design; cleaning one cup while using the other keeps jobs moving. Only downside: the 5L cups are great for volume, but a bit bulky for tight crawlspaces. Still, the electric efficiency beats hand pumps all day. Solid 4.5 stars—I’d round up if more nozzle options were included standard."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.7/5 ⭐ (94 Reviews)

Dr. Alan Foster - Construction Materials & Repair Systems Specialist

"The LW Electric PU Epoxy Injection System stands out in the grouting equipment market due to its scene adaptability and precision engineering. Its compliance with ISO 23932 ensures application accuracy critical for structural integrity. I particularly recommend the dual-cup design for contractors managing multi-resin workflows—it’s a productivity multiplier often overlooked in entry-level models."

Rebecca Liu - OSHA & CE Certification Advisor

"Few electric grout machines meet both CE and ISO standards for construction safety and performance. The LW model’s built-in pressure gauge, leak-proof seals, and reinforced construction make it one of the safest options on the market. Ideal for contractors needing documented compliance for infrastructure projects."

Posted: 2 days ago

"Used it on a highway overpass joint repair. The high-pressure output handled viscous epoxy perfectly. No drop in performance after hours of continuous use. Built like a tank."

Posted: 1 week ago

"Purchased the Advanced Model for our portfolio. Cuts repair time in half. Staff found it easy to learn. Customer support helped us pick the right nozzles for our most common crack types."

Posted: 3 weeks ago

"Handles everything from sidewalk joints to warehouse floors. Only wish the Pro Model was more affordable—we’ll upgrade once we scale up."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.