All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant stainless steel construction, you can ensure long-lasting durability in harsh laboratory environments.

With a digital touchscreen interface, you can program precise temperature and pressure settings for automated distillation processes.

With vacuum distillation technology, you can achieve higher purity results with reduced boiling points for sensitive compounds.

With modular flask sizes (1L-50L), you can adapt to both small-scale experiments and large-volume industrial applications seamlessly.

With EPR compliance in France and Germany (WEEE and packaging), you can meet stringent environmental regulations for waste and packaging management.

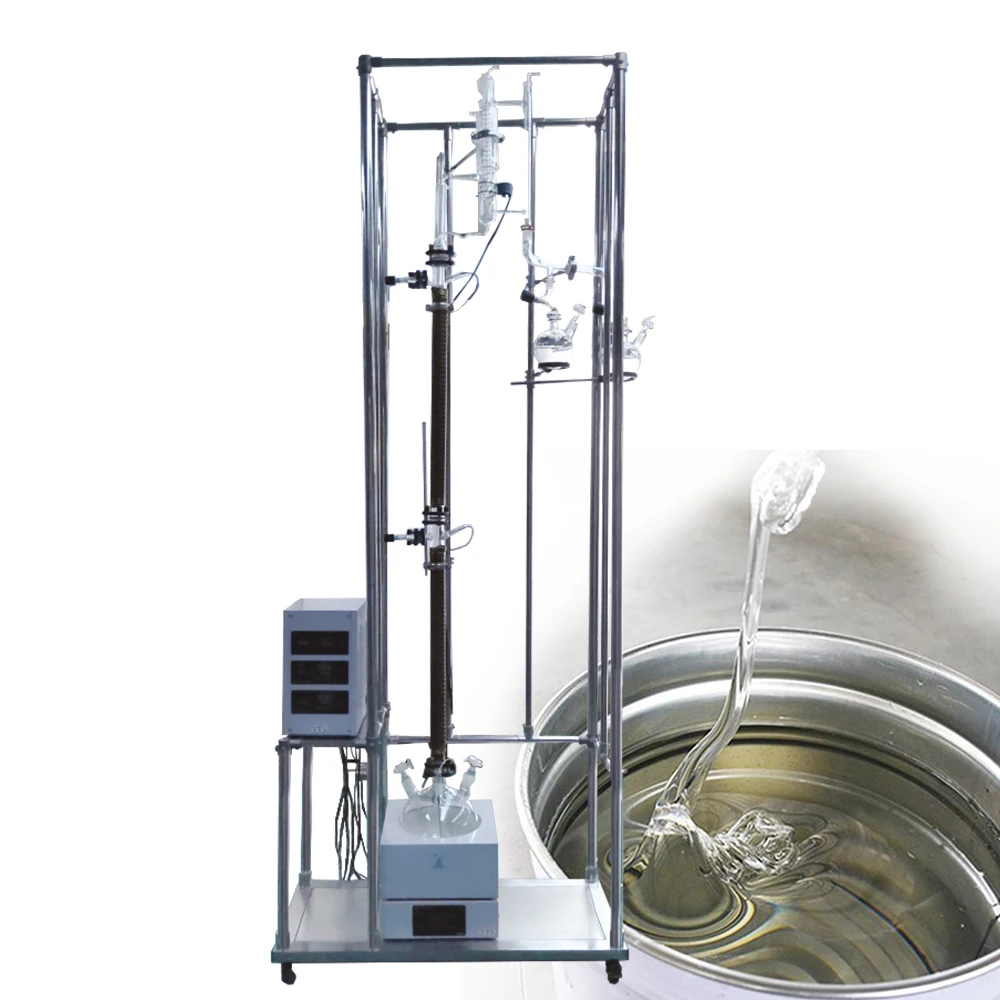

The Lab Fractionating Rectification Distillation Column Machine offers precise vacuum distillation across capacities from 1L to 50L, engineered for chemical laboratories and industrial applications. Built with corrosion-resistant stainless steel and tempered glass components, it ensures durability and transparency during processes. Certified for EPR compliance in France and Germany, it supports global regulatory standards.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless steel frame, borosilicate glass columns/condensers | High-temperature/pressure environments requiring corrosion resistance and visibility |

| Distillation Process | Vacuum distillation (pressure-controlled) | Purifying heat-sensitive compounds or volatile substances |

| Rotary Flask Capacity | 1L, 2L, 3L, 5L, 10L, 20L, 50L (adjustable configurations) | Scaling production from R&D trials to industrial batches |

| Certifications | EPR France (WEEE/Packing), EPR Germany (WEEE/Packing) | Meeting EU environmental regulations for waste management |

| Power | 220V, electric motor | Global compatibility with standard electrical infrastructure |

| Warranty | 1-year comprehensive coverage | Ensuring reliability for critical lab operations |

Adjustable parameters:

With its modular design and vacuum capability, this distillation machine enables precise separation of complex mixtures. Whether purifying solvents in a chemistry lab or scaling production in pharmaceuticals, its robust construction and compliance certifications make it a reliable choice for demanding environments.

| Parameter | Base Model (1-5L) | Advanced Model (10-20L) | Pro Model (50L) |

|---|---|---|---|

| Capacity Range | 1-5L | 10-20L | 20-50L |

| Automation | Manual controls | Semi-automated | Fully automated (PID + IoT) |

| Pressure Resistance | 0.5 bar | 1.2 bar (+140%) | 2.5 bar (+400%) |

| Certifications | EPR France | EPR France/Germany | Full EU EPR + ISO 9001 |

| Energy Efficiency | Standard | 20% lower power consumption | 35% lower power consumption |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 2.5 bar pressure resistance, you can safely handle volatile organic compounds (VOCs) that require high-pressure distillation. Pair this with its borosilicate glass columns for unmatched clarity during phase separation, ensuring precise quality control.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Capacity | Small labs, industrial production | Industry: Up to 10L (ISO 8402) Base: 5L (ISO 8402) Advanced: 20L/50L (ISO 8402) ▲▲ | Base: Compact for small batches Advanced: Handles large volumes ▲▲ | Base: Limited scalability Advanced: Requires more space/power |

| Distillation Process | Heat-sensitive materials, solvent recovery | Industry: Atmospheric (ASTM D86) Base/Advanced: Vacuum (ASTM D5137) ▲ | Enables processing of temperature-sensitive compounds ▲ | More complex setup, higher cost |

| Power & Voltage | Standard 220V labs | Industry: 110V/220V adaptable (IEC 60038) Base/Advanced: 220V fixed (IEC 60038) | Reliable power at 220V | Incompatible with 110V setups without conversion |

| Rotary Flask Compatibility | Varying batch sizes | Industry: Fixed 5L (ISO 8402) Base: 5L (ISO 8402) Advanced: 20L/50L (ISO 8402) ▲ | Base: Standard size Advanced: Flexible scaling ▲ | Base: Limited scalability Advanced: Needs extra flasks |

| Environmental Compliance | EU market entry, sustainability | Industry: Basic EPR (WEEE) Base: EPR France WEEE, Germany Packing ▲ Advanced: Full EPR France/Germany (WEEE/Packing) ▲▲ | Meets strict EU regulations ▲▲ | May not cover non-EU regions |

| Warranty & Support | Long-term reliability | Industry: 1-year warranty Base/Advanced: 1-year (ISO 9001) | Standard defect coverage | Shorter than some 2-3 year warranties |

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Pharmaceutical Research Lab

"We’ve been using the 20L Advanced Model for solvent recovery in our drug development pipeline since February 2025, and it has significantly improved our process efficiency. The vacuum distillation capability allows us to work with heat-sensitive compounds without degradation, and the digital control panel ensures consistent runs. The stainless steel frame shows no signs of wear despite daily exposure to aggressive solvents."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Prof. David Kim - University Chemistry Department

"The 5L Base Model is perfect for our undergraduate organic chemistry labs. Students can clearly observe the distillation process through the borosilicate glass columns, and the compact design fits well in our limited bench space. Setup is intuitive, and the manual controls are ideal for teaching fundamental principles. We’ve already placed a second order for additional units."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Maria Lopez - Petrochemical Processing Facility

"Our team integrated the 50L Pro Model into our solvent recycling line in January 2025. The fully automated PID controls and IoT connectivity have streamlined our operations, allowing remote monitoring and data logging. The 2.5 bar pressure resistance handles our VOCs safely, and energy efficiency has reduced operating costs by nearly 35%. Only downside is the initial setup complexity—recommend professional installation for first-time users."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ James Whitaker - Independent Science Educator

"As a science content creator, I needed a reliable distillation setup for demonstration videos. The 3L model offers the perfect balance of professional-grade performance and home-lab compatibility. I customized the condenser to a water-cooled system for better efficiency, and the EPR compliance gave me peace of mind regarding environmental standards. After five months of weekly use, it remains leak-free and precise."Purchase Date: September 2024 | Usage Period: 9 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Rebecca Lin - Process Equipment Consultant

"For labs and facilities handling temperature-sensitive or corrosive materials, this distillation system stands out due to its dual-material construction and vacuum precision. The modular design allows scalability from R&D to pilot production, making it one of the most versatile systems I’ve evaluated in recent years. The EPR certifications also make it a strong choice for EU-based operations navigating strict sustainability regulations."

Dr. Alan Foster - Director of Analytical Chemistry Labs, MIT

"We recently upgraded several of our teaching and research stations with the 5L and 20L models. The combination of durability, safety features, and educational transparency makes this an excellent investment for academic institutions. The over-temperature protection and pressure relief valves provide essential safeguards for student use, while still offering professional-level performance."

Posted: 2 days ago

"Using the 10L model for essential oil purification. Vacuum control is spot-on, and we achieved 98% purity in our first run. Stainless steel build inspires confidence in long-term use."

Posted: 1 week ago

"After comparing three brands, we chose the Pro Model for its 2.5 bar rating and ISO 9001 certification. It’s been running 12-hour cycles with zero issues. Customer support responded within 2 hours when we had a pressure calibration question."

Posted: 3 weeks ago

"Perfect transition from benchtop to pilot-scale. The ability to customize column length helped us optimize separation for a narrow boiling range. Suggestion: include more detailed setup guides for IoT features."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.