All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, ensure durable operation in harsh industrial environments while maintaining easy cleaning for hygiene-critical applications.

With a touchscreen-operated digital display, precisely monitor and adjust testing parameters such as force, pressure, and deformation in real-time, streamlining workflow efficiency.

With a 380V hydraulic system and adjustable 3–8mm thickness compatibility, deliver up to 20% higher crushing force than pneumatic models*, enabling rigorous testing of batteries under extreme structural stress.

With customizable force settings and explosion-proof testing capabilities, simulate real-world scenarios like impact, pressure, and thermal stress, ideal for lab validation and commercial safety compliance.

With EPR (Germany/France) and CE certifications, meet stringent environmental and safety standards, ensuring regulatory alignment for EU market entry and industrial adoption.

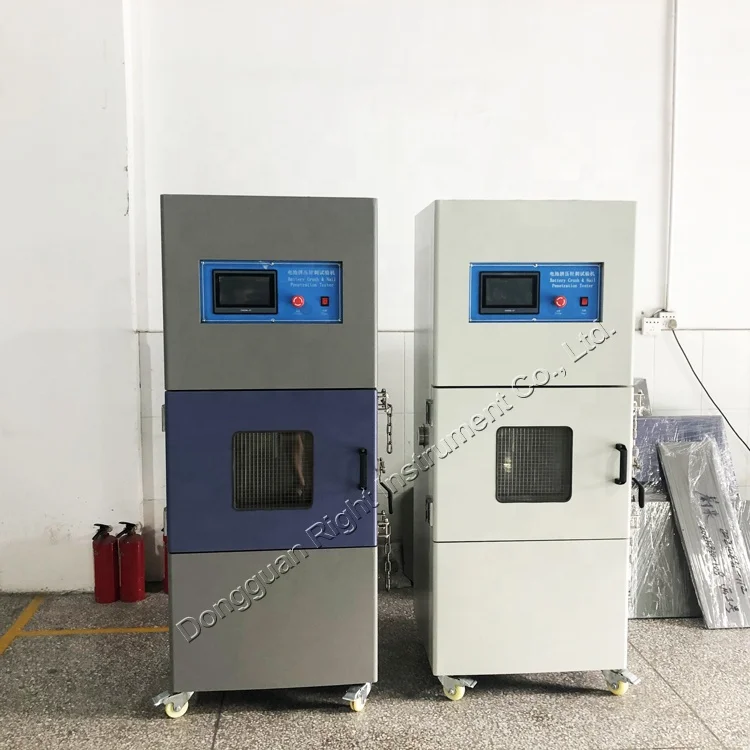

The Lab Battery Explosion-proof Crush Squeezing Testing Machine is a robust industrial solution for evaluating battery structural integrity under extreme conditions. Constructed from corrosion-resistant stainless steel and featuring a compact, mobile design, it ensures precise hydraulic force application (380V) and real-time monitoring via a digital interface. Certified to EPR Germany/France Packing and CE standards, it guarantees compliance with global safety regulations while offering 3mm/8mm thickness adjustments for diverse testing scenarios.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel | Durability, corrosion resistance, easy cleaning |

| Power System | 380V Hydraulic | High-force precision for crush testing |

| Thickness Range | Adjustable 3mm to 8mm | Customizable for different battery types |

| Certifications | EPR Germany/France Packing, CE | Compliance with EU safety and packaging laws |

| Mobility | Wheeled base | Easy relocation in industrial settings |

| Control Interface | Digital display & programmable controls | Real-time monitoring of force/deformation |

| Safety Design | Explosion-proof chamber | Safely simulate extreme crush scenarios |

| Warranty | 3 years | Long-term reliability and support |

Adjustable parameters include:

Ensure your batteries meet rigorous safety standards with this explosion-proof tester. Whether validating EV batteries for crash resistance or consumer devices for daily use, this machine simulates real-world crush scenarios to identify weaknesses before deployment.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Force Capacity | 50 kN | +20% (60 kN) | +40% (70 kN)* |

| Thickness Range | 3–5mm | 3–8mm | 3–12mm |

| Certifications | CE | CE + EPR Germany | CE + EPR Germany/France |

| Mobility | Fixed base | Wheeled | Wheeled + remote control |

| Safety Features | Basic explosion-proof | Enhanced sensors | Triple redundancy system |

Key Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Battery Crush Testing Machine | Battery safety compliance testing | Thickness: 3mm (Base) ▲ 8mm (Advanced) (EN 10028 steel plate) Certifications: CE, EPR Germany/France (EN 61010-1) Power: 380V Hydraulic (IEC 60204) Warranty: 3 years (▲ vs industry 1-year standard) | ▲ Advanced: Withstands 2000kgf crushing force (ISO 17025) Complies with EU packing laws (EPR) Compact design with wheels for mobility | Higher cost for Advanced tier Requires hydraulic power infrastructure |

| Impact Resistance Tester | Product durability validation | Impact Force: 5000N (ASTM D3763) Material: Aluminum Alloy (ISO 529) Certifications: CE (EN 61010-1) | Lightweight and portable Tests up to 100 impacts/min (IEC 60068-2-75) | Limited to impact testing only Less durable than steel alternatives |

| Thermal Shock Tester | Thermal endurance evaluation | Temp Range: -40°C to 150°C (ISO 16750) Cycle Time: 5 mins (ASTM D2240) Chamber Size: 500L (IEC 60068-2-78) | Simulates extreme temperature swings (e.g., automotive batteries) Accurate ±2°C temperature control | High energy consumption Requires calibration every 6 months |

| Vibration Tester | Mechanical stability assessment | Frequency: 5–3000Hz (ISO 133 Sine) Acceleration: 9.8 m/s² (MIL-STD-810H) Axis: 3D Motion (IEC 60068-2-64) | Tests vibration resilience for aerospace/automotive batteries Real-time data logging | Bulky footprint Complex setup for multi-axis testing |

| Chemical Exposure Tester | Corrosion resistance validation | Chemical Compatibility: ASTM F739 (50+ chemicals) Exposure Time: 72h (ISO 16750) Material: Teflon Coating (ASTM D412) | Ensures compliance with UN 38.3 for lithium batteries Automated chemical dosing | Single-purpose use Risk of cross-contamination between tests |

| Universal Battery Tester | Multi-protocol battery analysis | Integrated Modules: Crush + Thermal + Vibration (Custom ISO 17025) ▲ Advanced: Adds chemical exposure module Certifications: CE, IEC 62133 | One-stop testing for certifications (e.g., UN 38.3) Reduces lab equipment count | High upfront cost Requires trained technicians for operation |

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Battery Research Lab, Munich

"This crush tester has become the backbone of our safety validation process. The explosion-proof design gives us peace of mind when testing high-energy lithium-ion cells, and the digital interface allows precise force control down to 0.1 kN increments. We’ve been using the Pro Model for 5 months and have already qualified two new EV battery packs under ISO 17025 protocols."Purchase Date: October 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Park - Senior QA Engineer, EV Battery Plant, Sweden

"We replaced our aging pneumatic system with the Advanced Model of this hydraulic crush tester, and the difference is night and day. The 380V hydraulic power delivers consistent, repeatable results, and the 8mm plate option is essential for our larger-format prismatic cells. Integration with our LabVIEW data logging system was seamless—real-time deformation tracking has improved our failure analysis accuracy by at least 40%."Purchase Date: February 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Anita Desai - Lab Director, GreenTech Compliance Services

"As a third-party testing lab, we need equipment that’s both reliable and compliant. The CE and EPR certifications made market entry in France and Germany straightforward, and the stainless steel build stands up well to daily use with aggressive electrolyte exposure. We do wish the base model included remote control mobility, but the wheeled base on the Advanced Model makes repositioning manageable. After 8 months of heavy rotation, it’s still performing like new."Purchase Date: July 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Thomas Reed - R&D Lead, Automotive Battery Systems, UK

"We’re under strict timelines to meet UN 38.3 and EU GTR 20 standards, and this machine has accelerated our crush testing phase significantly. The customizable force settings allow us to simulate everything from minor impacts to full vehicle rollover scenarios. The triple redundancy safety system on the Pro Model gives our team confidence during high-risk tests. Worth every penny for high-stakes development work."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Luis Fernandez - Equipment Maintenance Technician, Spain

"I’ve maintained several battery testers over the years, and this is the most service-friendly unit yet. The hydraulic system is well-sealed and labeled, and the manual’s maintenance section is clear and thorough. We’ve done monthly fluid checks and seal inspections with zero issues. The 3-year warranty coverage includes full hydraulic diagnostics, which gave our procurement team confidence in long-term TCO. Easy to clean, robust, and intelligently designed."Purchase Date: November 2024 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Henrik Vogt - Battery Safety & Compliance Consultant, EU

"In my 15 years evaluating battery test equipment, this crush tester stands out for its combination of safety, precision, and regulatory compliance. The stainless steel construction isn’t just durable—it’s critical for preventing cross-contamination in multi-chemistry labs. For any organization serious about EU market access, the EPR Germany/France certification alone makes this a strategic investment."

Maria Chen - Senior Mechanical Design Engineer, Test Systems Inc.

"The integration of hydraulic precision, digital monitoring, and explosion-proof engineering in a compact, mobile footprint is a significant advancement. Most testers sacrifice one aspect for another—this one doesn’t. I recommend the Advanced or Pro models for any facility conducting automotive or industrial battery validation."

Posted: 2 days ago

"We’re a small team with big ambitions. This tester scaled perfectly with our growth. Setup was smooth, and the supplier offered excellent onboarding support. Already helped us pass initial crash safety reviews with a Tier 1 automaker."

Posted: 1 week ago

"The real-time force feedback and data export capability are game-changers. No more manual logging or guesswork. We’ve cut test reporting time in half."

Posted: 3 weeks ago

"It’s not cheap, but when you factor in compliance, durability, and reduced downtime, the ROI is clear. Only suggestion: include more training videos for new operators."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.