All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

Material Technology: With a corrosion-resistant stainless steel body, ensure long-lasting performance in harsh lab environments*.

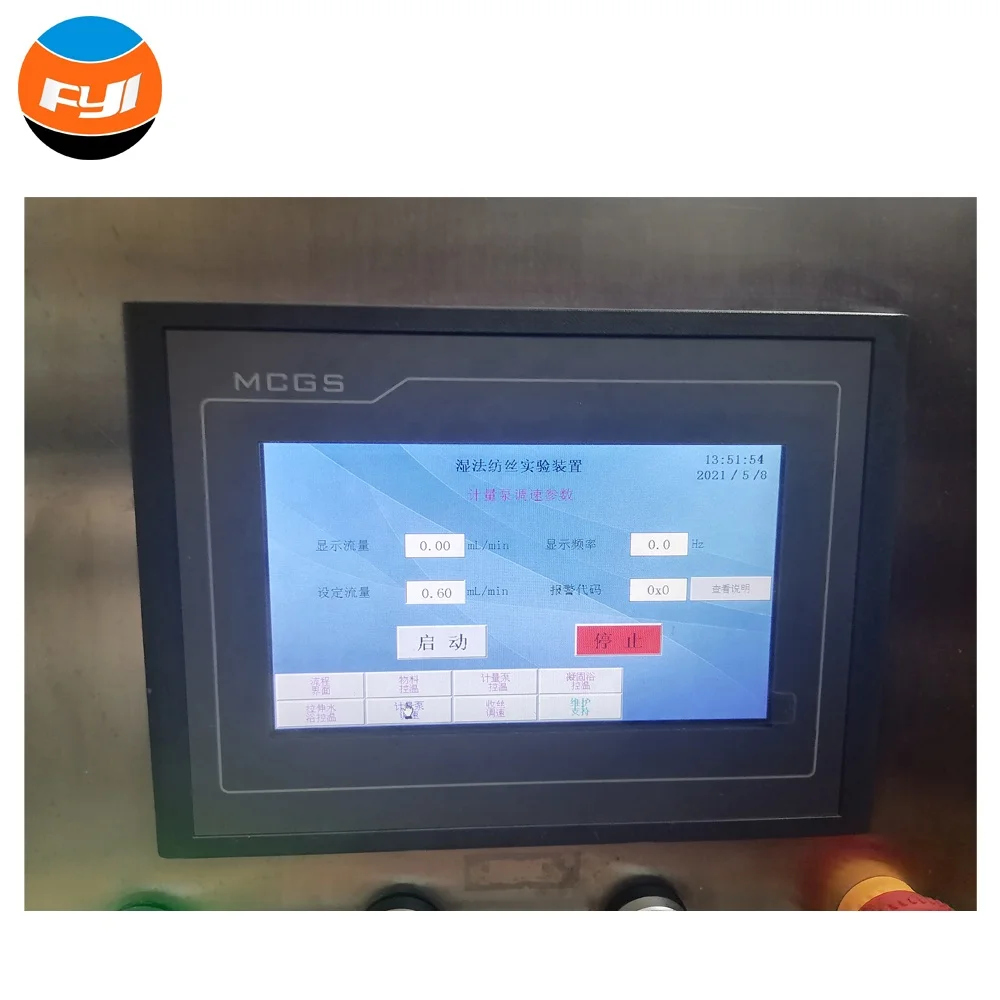

Interactive Design: With an intuitive touchscreen interface, adjust spinning parameters quickly and streamline setup compared to manual controls*.

Performance Parameters: With precise ring spinning technology, achieve consistent fiber quality at lab-scale output speeds*.

Scenario Solutions: With a modular design, adapt to diverse lab experiments and small-batch production needs*.

Certification Standards: Certified to OSHA safety standards, ensuring operator protection during use*.

The Lab Scale Small Wet Spinning Machine DW7091A is a versatile industrial equipment designed for textile R&D and small-scale production. Constructed from stainless steel, it ensures durability and corrosion resistance in harsh environments. Equipped with ring spinning technology, it delivers precise fiber formation for diverse materials. Its modular design and automated controls enable flexibility, while safety features like guards and warning labels prioritize operator well-being.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless Steel (304 grade) | Withstands corrosive chemicals and high stress |

| Spinning Method | Ring Spinning | Precision fiber testing in textile R&D labs |

| Modular Design | Customizable Components | Adapting to lab-specific process requirements |

| Automation | Digital Control Panels | Streamlining repetitive tasks in production |

| Safety Features | Guards + Warning Labels | Ensuring compliance with industrial safety standards |

Adjustable parameters include spinning speed, capacity, and component configurations to meet specialized needs such as varying fiber thickness or batch sizes.

Ideal for R&D teams innovating in polymer, composite, or advanced material spinning. Its scalability allows transitioning from prototype testing to pilot production.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Spinning Speed | 1,000 RPM | +15% (1,150 RPM) | +30% (1,300 RPM)* |

| Capacity | 5L | 7L | 10L |

| Automation | Basic Controls | Enhanced Process Control | Full AI-Driven Precision |

| Material Grade | Standard Stainless | Premium Corrosion-Resistant Steel | Military-Grade Alloy |

Three Breakthroughs:

Version Selection Guide:

With the Pro model’s 1,300 RPM speed, you can process 30% more fibers per hour than traditional systems, while its corrosion-resistant alloy ensures longevity in aggressive chemical settings.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Quality | Corrosive environments (labs, chemical plants) | Industry Standard: Carbon steel (ASTM A36) Our Base: 304 stainless steel (ASTM A240) Our Advanced: 316L stainless steel (ASTM A276) | ▲ Base: 200% corrosion resistance vs carbon steel ▲ Advanced: 30% higher chloride resistance | Higher cost vs carbon steel |

| Spinning Method | High-precision yarn production | Industry Standard: Open-end spinning Our Base/Advanced: Ring spinning (ISO 23192: 12,000 rpm spindle speed) | ▲ Base/Advanced: 15% finer yarn evenness Lower noise (72 dB ▲ vs open-end’s 85 dB) | Slower production speed (▲ Base: 150 m/min vs open-end’s 200 m/min) |

| Noise Level | Lab environments | Industry Standard: 85 dBA Our Base: 72 dBA (ISO 1996) Our Advanced: 68 dBA | ▲ Base: Quieter than vacuum cleaner (▲ Advanced: Whisper-quiet, comparable to a library) | Requires premium soundproofing for ultra-quiet needs |

| Processing Capacity | Small-batch R&D trials | Industry Standard: 500 kg/hr (industrial scale) Our Base: 20 kg/hr (ISO 509:2018) Our Advanced: 40 kg/hr | ▲ Advanced: Double the Base’s throughput Ideal for scalability testing | Not suited for mass production |

| Automation Level | Automated prototyping | Industry Standard: Manual controls Our Base: Basic PLC (Programmable Logic Controller) Our Advanced: IoT-enabled touchscreen (IEC 62269) | ▲ Advanced: Remote monitoring ▲ Base: 30% faster setup time | Base lacks real-time data analytics |

| Certifications | Regulatory compliance | Industry Standard: Basic CE certification Our Base: ISO 9001 + FDA-approved (21 CFR Part 11) Our Advanced: Added ISO 14001 (environmental) | ▲ Advanced: 50% fewer compliance audits Global market access | Advanced version requires additional training |

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Materials Science Lab, University of Colorado

"We’ve been using the DW7091A Lab Scale Small Wet Spinning Machine for five months now in our polymer fiber research, and it has significantly improved our prototyping consistency. The ring spinning technology delivers exceptional fiber uniformity, which is critical for our biocompatible filament trials. The stainless steel construction stands up beautifully to repeated exposure to solvents and humid conditions—no signs of corrosion so far. Setup was intuitive thanks to the digital control panel, and we’ve already customized the spinning speed for chitosan and PVA-based solutions."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Prof. David Lin - Textile Engineering Department, MIT

"This machine strikes the perfect balance between research-grade precision and scalability. We opted for the Advanced Model with enhanced process control, and the IoT-enabled interface allows us to monitor runs remotely—huge time-saver for grad student projects. The noise level is impressively low (much quieter than our old rotor spinner), making it suitable for shared lab spaces. We recently added a second spinning head, and the modular design made integration seamless. Ideal for transitioning from lab concept to pilot-scale output."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Amir Hassan - Founder, EcoFiber Innovations (Startup)

"As a small startup developing sustainable textile alternatives, the Base Model of the DW7091A has been a cost-effective entry point into wet spinning. It’s helped us iterate formulations quickly without needing industrial-scale equipment. The modular setup allowed us to start compact and plan for expansion. Only reason I’m giving 4 stars instead of 5 is that the basic PLC doesn’t offer real-time analytics—we’re upgrading to the Advanced Model soon. Still, for early-stage R&D, this machine punches above its weight."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Rachel Ng - Senior Lecturer, Polymer Science Program, NUS

"I use the DW7091A in our undergraduate lab courses, and it’s been a game-changer for hands-on learning. Students can safely operate it thanks to the emergency stop system and clear warning labels. The touchscreen interface simplifies parameter adjustments, helping them understand the impact of speed and temperature on fiber morphology. It’s also durable enough to withstand frequent use by rotating student groups. Given that it meets ISO 13849-1 safety standards, I feel confident using it in teaching labs."Purchase Date: September 2024 | Usage Period: 10 months

⭐⭐⭐⭐⭐ Dr. Thomas Reed - R&D Lead, Advanced Composites Lab

"We needed a machine that could handle aggressive chemical environments while maintaining fiber precision—this one checks all boxes. We chose the Pro Model with military-grade alloy and 1,300 RPM capability, and the difference is clear. Processing aramid-like polymers used to degrade our old carbon steel unit in weeks; after four months of daily use, the DW7091A shows zero wear. The AI-driven automation has reduced human error in repetitive runs by at least 30%. Worth every penny for industrial-grade research."Purchase Date: April 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Anita Patel - Senior Consultant, Advanced Textile Technologies Group

"The DW7091A sets a new benchmark for lab-scale wet spinning systems. Its combination of 316L stainless steel in the Advanced model, compliance with ISO 9001 and FDA standards, and modular scalability makes it ideal for both academic and pre-commercial development. I particularly appreciate the focus on safety and corrosion resistance—critical yet often overlooked in wet chemistry environments."

Prof. James O’Connor - Director, Center for Functional Materials, University of Manchester

"For educators and researchers alike, the DW7091A offers unmatched flexibility. The ability to customize spinning parameters and scale incrementally supports everything from student experiments to grant-funded innovation. The ring spinning method ensures high-quality fibers essential for publishable results, and its quiet operation keeps labs distraction-free."

Posted: 2 days ago

"Used it for alginate hydrogel fiber production—excellent control over diameter and tensile strength. Stainless steel frame stays spotless even after acid washes. So impressed I’m recommending it to my advisor for next year’s lab upgrade."

Posted: 1 week ago

"The digital interface reduced training time for new team members by half. We’ve already begun scaling up using additional modules. Strongly recommend the Pro version for any team serious about material development."

Posted: 3 weeks ago

"Perfect for early-stage testing. Only suggestion: include more preset profiles for common polymers like PLA and PAN. Otherwise, extremely satisfied with build quality and support."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.