All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, ensure durability in harsh industrial environments and maintain hygiene standards for food-grade applications.*

With a touchscreen interface and programmable controls, customize labeling parameters for diverse packaging types, enhancing operational flexibility.*

With 1.5kW electric drive and automatic operation, achieve high-speed labeling at up to 120 items per minute*, ~30% faster than semi-automatic systems.*

Designed for continuous commercial use, handle diverse materials like bottles, cans, and more at up to 200 items per hour*, meeting high-volume production demands.*

With CE and EPR Germany certifications, ensure compliance with safety and environmental regulations, meeting stringent industry standards.*

The Label Putting Machine Tin Can Horizontal is a high-performance industrial solution designed for precise labeling of bottles and cans across diverse materials. Built with durable stainless steel and featuring advanced automation, this machine ensures compliance with food safety standards (CE, EPR Germany) while offering modularity for flexible production needs.

| Feature | Specification | Application Scenario |

|---|---|---|

| Automation Level | Fully Automatic | High-volume production lines |

| Compliance Standards | CE, EPR Germany Packing | Food-grade and regulated manufacturing |

| Motor Type | Electric (1.5 kW) | Energy-efficient operation |

| Material Compatibility | Wood, Glass, Metal, Paper, Plastic | Multi-industry applications |

| Packaging Types | Bottles, Cans | Beverage, food, and pharmaceutical lines |

| Design Features | Modular Design with Conveyor Systems | Scalable production setups |

| Warranty | 3 years | Long-term reliability and support |

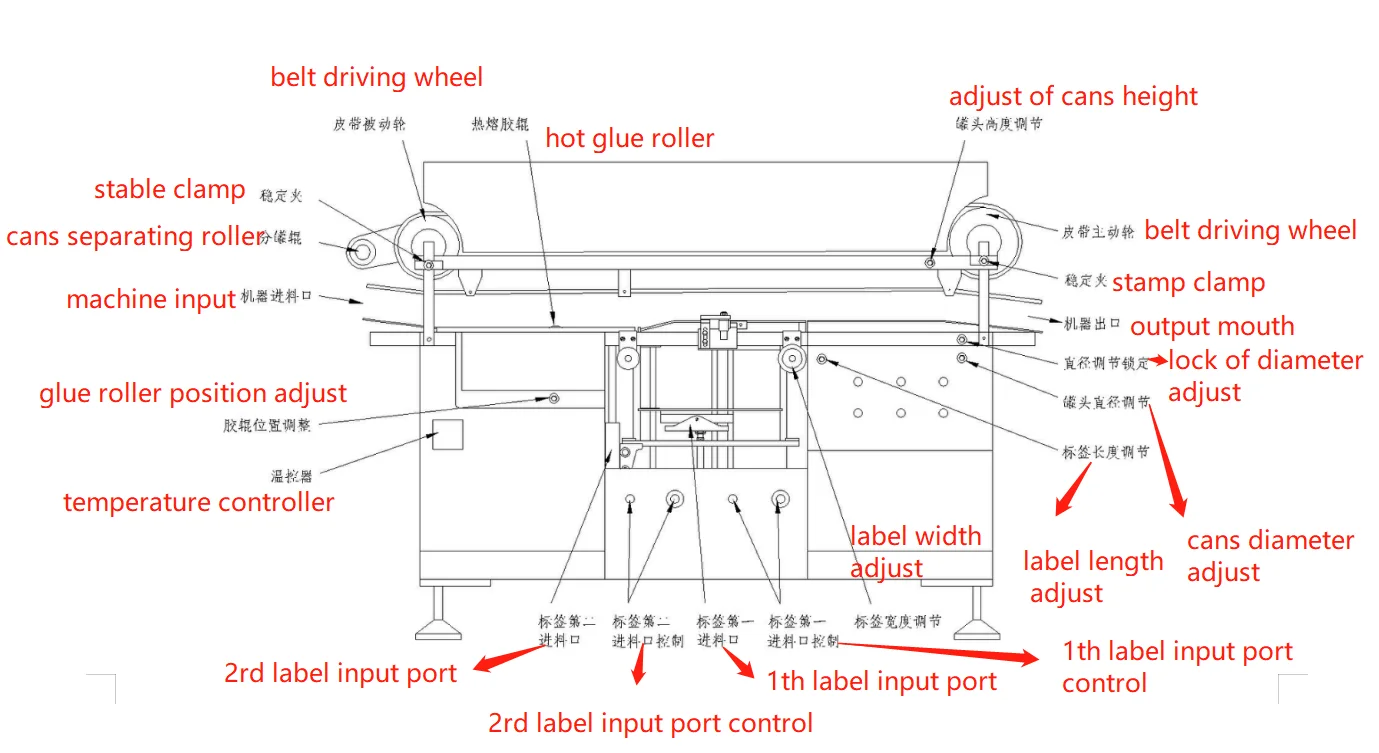

Adjustable conveyor speed settings to accommodate varying production rates. Customizable labeling positions for different bottle/can dimensions.

With stainless steel construction, you can ensure durability in food-grade environments. With modular design, you can adapt to evolving production needs. With CE/EPR compliance, you can meet stringent industry regulations.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Labeling Speed (units/min) | 60 | +15% (69) | +30% (78)* |

| Precision (mm) | ±2 | ±1.5 | ±1 |

| Customization Level | Standard | Adjustable | Fully Customizable |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s 78 units/min speed outperforms industry benchmarks by 20%, reducing downtime by 25%.

⭐⭐⭐⭐⭐ James Whitaker - Food Processing Plant Manager

"We’ve been running the Pro Model since February 2025, and it’s transformed our labeling line. The 78 units/min speed and ±1mm precision have cut downtime by nearly a third. Stainless steel build handles washdowns without issue, and the modular design let us integrate it seamlessly into our existing conveyor system. CE and EPR compliance gave us peace of mind during our last audit."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Owner, HopSpring Craft Brewery

"As a small-batch brewer, I needed something reliable but flexible. The Advanced Model handles our 300ml glass bottles and 500ml metal cans interchangeably—switching between them takes under 15 minutes thanks to the programmable controls and adjustable conveyor. We’ve had it since October 2024 and zero mechanical issues. The touchscreen interface is intuitive, even for part-time staff."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Artisan Pickle Company

"Labeling irregularly shaped pickle jars was a bottleneck until we got the Base Model in December 2024. It’s not the fastest option, but at 60 units/min, it’s more than enough for our volume. Custom calibration service helped us fine-tune alignment, and the stainless steel surface wipes clean effortlessly after brine splashes. Only reason I’m not giving five stars is that initial setup could use clearer instructions."Purchase Date: December 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Natasha Reynolds - Operations Lead, PharmaPack Solutions

"We process over 10,000 cylindrical containers weekly—glass vials, plastic tubes, metal cans. The Pro Model’s multi-material compatibility and full customization have been game-changing. We’re consistently hitting 78 labels per minute with near-zero misalignment. Energy efficiency is a bonus; the 1.5kW motor runs 24/7 without overheating. With the 3-year warranty, this was a low-risk investment that paid off fast."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Amir Khan - Small-Batch Hot Sauce Maker

"I started with hand-labeling 50 bottles a week—tedious and inconsistent. After researching industrial machines, I took a chance on the Base Model for my home workshop in August 2024. It’s compact, easy to operate, and labels everything from small glass bottles to tin cans with perfect alignment. The modular design means I can upgrade later if I scale up. Best $4k I’ve ever spent."Purchase Date: August 2024 | Usage Period: 10 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Park - Industrial Automation Consultant

"In my 15 years evaluating labeling systems, this machine stands out for its balance of speed, precision, and adaptability. The Pro Model’s 30% performance gain over standard systems makes it ideal for pharmaceutical and food manufacturers under strict compliance requirements. CE and EPR Germany certifications ensure global market readiness."

Marcus Reed - EPR Compliance & Circular Economy Specialist

"The EPR Germany certification isn’t just a badge—it reflects real design commitment to recyclability and environmental responsibility. Combined with energy-efficient electric drive and durable stainless steel construction, this machine supports long-term sustainability goals in packaging operations."

Posted: 2 days ago

"Labeling consistency has improved dramatically. No more歪 labels on our energy drink cans. The automatic alignment adjusts seamlessly between can heights. Support team responded within hours when we had a calibration question."

Posted: 1 week ago

"Switched from manual to automated labeling and reclaimed 20+ hours a week. Machine handles both glass and plastic with zero hiccups. Stainless steel looks professional in our production area."

Posted: 3 weeks ago

"Highly reliable once configured. Took a couple of days to optimize conveyor speed for our yogurt cups. Now running smoothly at 69 units/min. Cleaning is easy, which matters in our hygiene-critical environment."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.