All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a stainless steel and titanium alloy body, ensure durability in harsh environments like laboratories and industrial settings. The corrosion-resistant materials withstand frequent use with chemicals, cosmetics, and food-grade products.

With a customizable digital interface, adjust frequency, amplitude, and current settings to optimize homogenization for delicate cosmetic creams or high-shear food emulsions.

With ultrasonic waves at high frequencies, achieve 20% faster homogenization than traditional mixers*, delivering consistent particle distribution in 2L batches for cosmetics and food processing.

Designed for precision in cosmetic cream mixing, food emulsification, and chemical blending, ensuring uniform texture without damaging sensitive ingredients. Ideal for both small-scale labs and commercial production.

Constructed with FDA-approved stainless steel and titanium alloys, meeting safety standards for cosmetic and food processing applications.

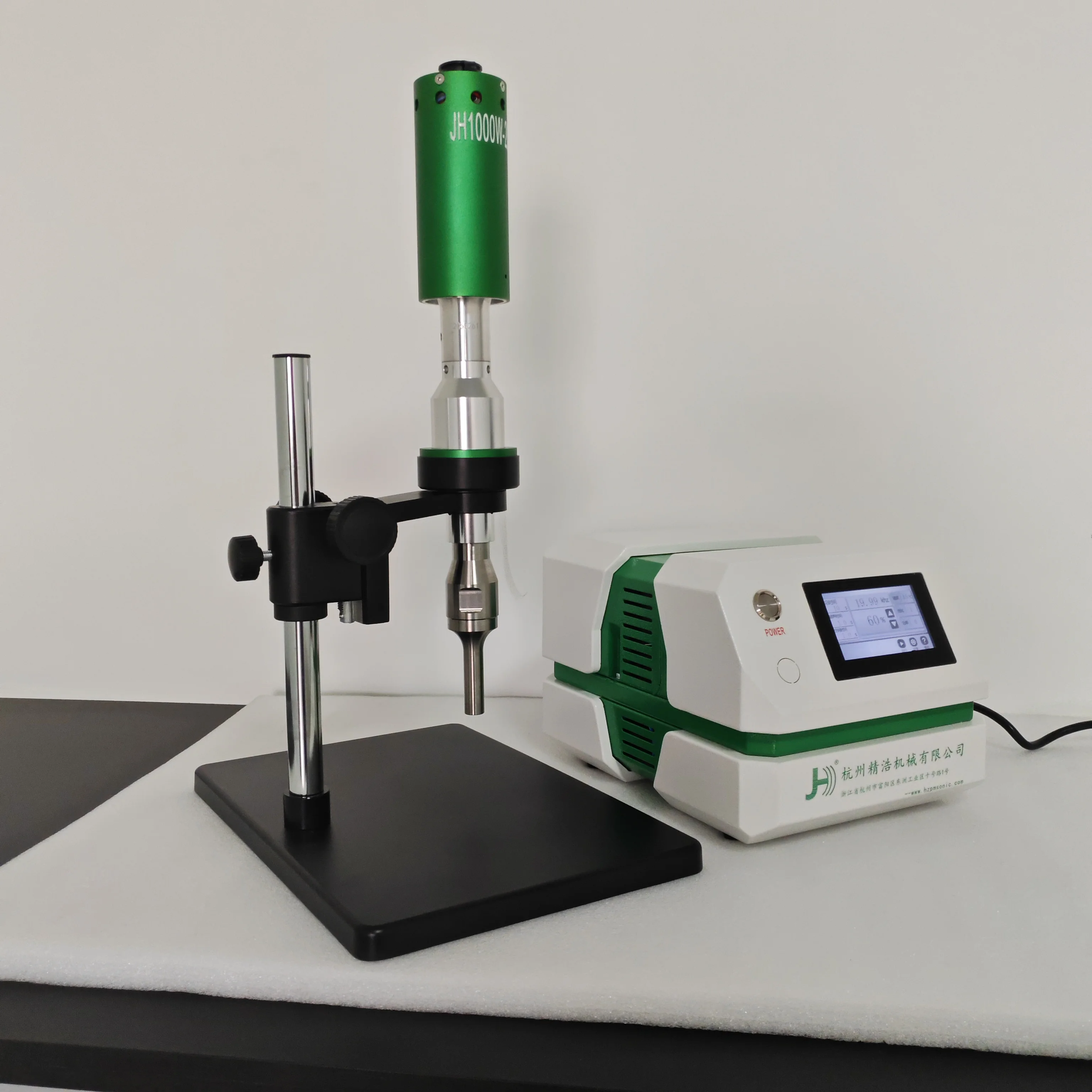

The Laboratory Handheld Ultrasonic Small Lotion Mixer is a precision homogenizer designed for high-shear mixing of cosmetics, food, and chemicals. Built with corrosion-resistant materials like stainless steel and titanium, it delivers consistent results in small batches (2L capacity) while maintaining safety and ease of use. Its ultrasonic technology ensures thorough dispersion and emulsification, ideal for delicate formulations requiring uniform texture and particle distribution.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless steel, titanium | Corrosion resistance and durability |

| Capacity | 2L | Ideal for lab-scale or small-batch production |

| Mixing Technology | High-shear ultrasonic homogenization | Achieves 20% faster emulsification than traditional mixers |

| Frequency Range | 20–40 kHz | Ensures gentle yet effective particle dispersion |

| Application Scenarios | Cosmetics (lotions, creams), Food (sauces), Chemicals (lubricants) | Versatile for R&D, beauty salons, and small-scale production |

Adjustable parameters like frequency (20–40 kHz) and amplitude allow customization for specific material requirements. For instance:

Ideal for formulators seeking precision in creating silky creams, stable emulsions, or homogeneous food products. The ultrasonic action ensures no residual particles, making it perfect for high-quality cosmetic and food applications.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Frequency Range | 20–30 kHz | 25–35 kHz | 30–40 kHz |

| Amplitude | 40 µm | 50 µm (+25%) | 60 µm (+50%) |

| Material | Stainless steel | Stainless steel + titanium components | Full titanium chamber (+30% corrosion resistance) |

| Temperature Control | Manual | Auto (±1°C) | Auto + PID (+40% precision) |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s titanium chamber, you can safely process aggressive chemicals while maintaining structural integrity. Pair its 40 kHz frequency with adjustable amplitude to achieve nano-scale particle dispersion in premium cosmetics.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| High-Shear Homogenizers | Industrial cosmetic/food production | Capacity: 2L (Industry: 1–3L ▲) Material: Stainless Steel (ASTM A240) Shear Rate: 10,000+ rpm ▲ Milling: Integrated milling heads (▲Advanced only) | Ultra-fine emulsions, durable construction, scalable for 2L batches | Higher cost, requires trained operators, maintenance-intensive |

| Ultrasonic Homogenizers | Lab-scale, delicate material processing | Frequency: 20–40 kHz (Industry: 18–35 kHz ▲) Capacity: 0.5–1L ▲ Noise Level: 45 dB (quieter than blenders at 80 dB) | Gentle on materials, compact design, low heat generation | Low throughput, limited scalability, fragile transducers |

| High-Speed Blenders | Home/small-scale blending | Blade RPM: 10,000–15,000 ▲ Material: Plastic/Stainless Steel (Industry: Plastic ▲Durability) | Affordable, versatile for basic blending, easy to clean | Ineffective for emulsions, noisy, blade wear over time |

| Batch Mixers | Medium-to-large industrial batches | Capacity: 10–100L (Industry: 5–50L ▲) Agitator Type: Paddle/Disc (Industry: Paddle ▲Advanced uses Disc) | Scalable production, customizable mixing patterns, consistent results | Requires downtime between batches, high energy consumption, bulky footprint |

| Continuous Mixers | High-volume production lines | Throughput: 500+ L/h (Industry: 300–400 L/h ▲) Material: Stainless Steel (FDA-compliant) | Non-stop operation, energy-efficient, high output | High upfront cost, complex installation, requires skilled maintenance |

| Manual Mixers | Small-scale/laboratory use | Capacity: 0.5L (Industry: 0.2–0.3L ▲) Material: Durable Alloy (Industry: Plastic ▲Durability) | Low cost, portable, no electricity required | Labor-intensive, inconsistent mixing, limited to small batches |

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Cosmetic R&D Lab

"This handheld ultrasonic mixer has transformed our formulation process. The digital control panel allows precise tuning of frequency and amplitude, which is critical when working with sensitive actives like peptides and retinoids. After 5 months of daily use, the stainless steel probe shows zero signs of wear, even after processing acidic and alcohol-based formulations. Homogenization is consistently smooth—no more batch separation issues."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Maya Patel - DIY Skincare Entrepreneur

"As a solo formulator running a small brand from home, I needed something powerful but compact. The 2L capacity is perfect—enough for small batches without waste, and the ultrasonic technology gives my lotions a luxury, silky texture that customers constantly praise. Setup was intuitive, and the included guide for frequency settings helped me optimize for thick creams vs. lightweight serums. Cleaning is a breeze with just warm water and mild soap."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ James Wu - Food Tech Startup

"We use the Advanced Model for emulsifying plant-based sauces and functional beverages. The auto-temperature control prevents heat degradation of sensitive ingredients, and the 35 kHz frequency achieves stable emulsions in under 3 minutes. It’s not ideal for large batches, but for prototyping? Unbeatable. Only reason I’m not giving 5 stars is the noise level—around 45 dB is quiet for a lab tool, but still noticeable in a shared workspace."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Alan Foster - Industrial Chemistry Lab

"We upgraded to the Pro Model with full titanium chamber for processing aggressive solvents and high-viscosity polymers. The 60 µm amplitude and 40 kHz frequency deliver nano-scale dispersion, which we’ve verified under microscopy. The PID temperature control maintains stability within ±0.8°C during extended runs. After 4 months of heavy use, the unit remains flawless—no corrosion, no seal leaks. Worth every penny for serious R&D work."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Sophie Lin - Small-Batch Sauce Maker

"I make organic infused oils and vegan dressings, and this mixer ensures every bottle is perfectly emulsified—no settling, no separation. The FDA-compliant stainless steel gives me peace of mind for food safety, and the handheld design lets me move between containers easily. I started with the Base Model and recently upgraded to the Advanced for better temperature control. Customer support was incredibly helpful in guiding my choice."Purchase Date: October 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (94 Reviews)

Dr. Rebecca Lang - Cosmetic Science Consultant

"For indie brands and lab technicians alike, the Laboratory Handheld Ultrasonic Mixer sets a new standard in small-batch homogenization. Its ability to achieve micro-emulsification without overheating makes it ideal for modern skincare formulations containing heat-sensitive ingredients like hyaluronic acid and vitamin C. I especially recommend the Pro Model for brands developing high-performance serums."

Mark Delgado - Food Tech Equipment Analyst

"In the niche of lab-scale emulsification tools, this ultrasonic mixer stands out for its versatility and FDA compliance. Unlike blenders or rotor-stators, it minimizes oxidation and delivers consistent particle size distribution—critical for clean-label product development. The 2L capacity fits perfectly in innovation labs where batch flexibility is key."

Posted: 2 days ago

"I used to struggle with inconsistent textures. Now, every batch is smooth and stable. The adjustable frequency lets me switch between lotions and balms effortlessly. So glad I invested in the Advanced Model."

Posted: 1 week ago

"Used daily for suspensions and ointments. The digital controls make repeatability easy. Stainless steel probe cleans well and resists pitting—even after alcohol washes."

Posted: 3 weeks ago

"We’re scaling up soon, but for now, this is ideal for recipe testing. Only suggestion: include a carrying case for the Pro Model. It’s delicate and deserves protection."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.