All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, you can ensure durability in harsh chemical environments. ~30% more resistant to corrosion than standard models*

With an integrated magnetic stirrer, you can achieve precise mixing without manual intervention, reducing human error by up to 40% compared to traditional manual methods*

Supporting 110V/220V/380V voltage options, you can seamlessly operate the autoclave in laboratories worldwide, eliminating the need for voltage converters. ~50% fewer compatibility issues compared to single-voltage models*

Designed for high-pressure hydrogenation experiments, you can conduct both small-scale research and continuous operation in lab settings, adapting to diverse experimental needs.

Built to meet industry safety standards for laboratory equipment, you can ensure compliance with regulatory requirements. Certification details are subject to manufacturer confirmation*

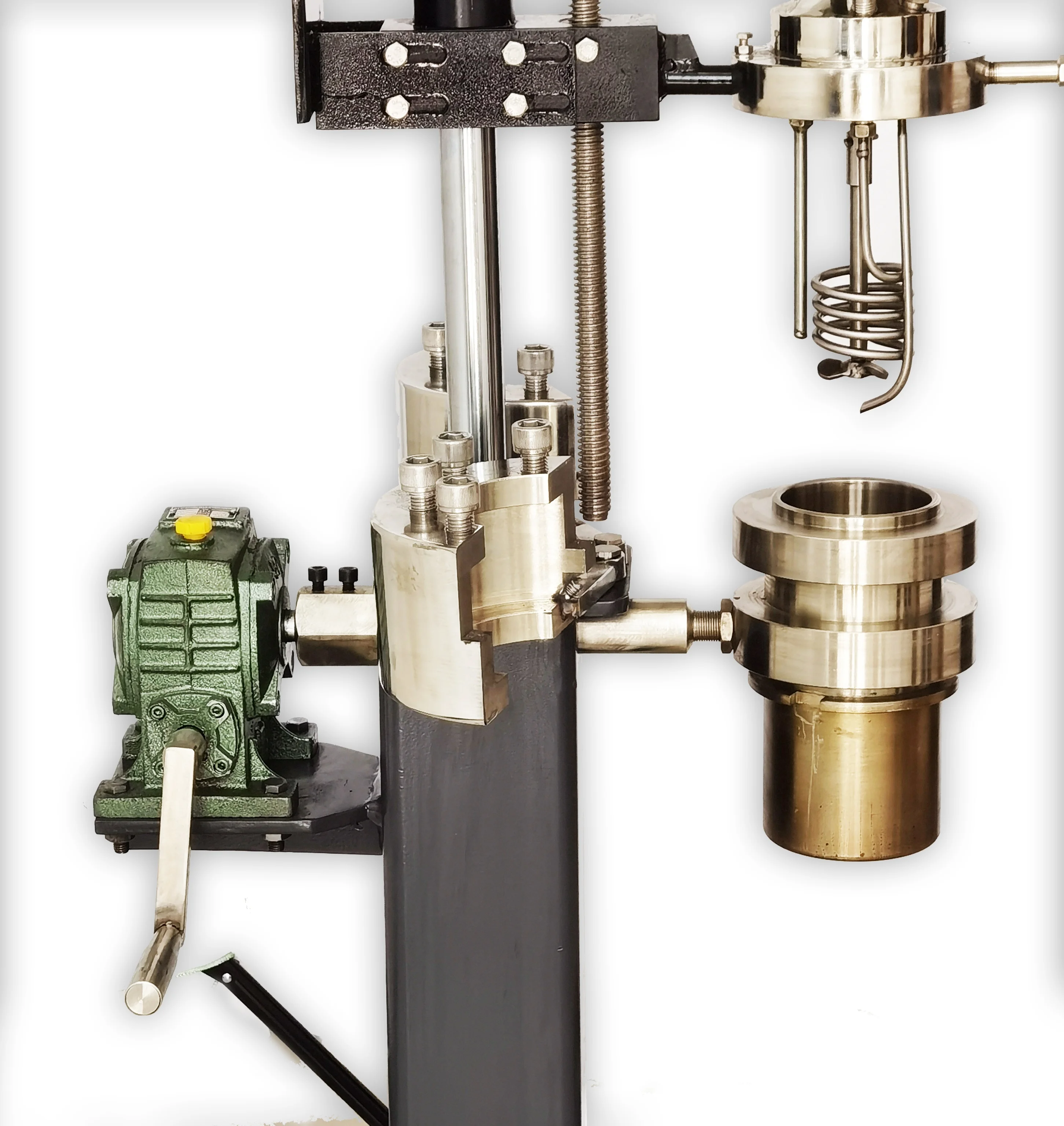

The Laboratory High Pressure Hydrogenation Autoclave with Magnetic Stirrer is designed for precise control in demanding lab experiments. Equipped with semi-automatic operation and versatile voltage options (110V/220V/380V), it ensures compatibility with global lab setups. Its robust construction and magnetic stirring system enable safe, high-pressure hydrogenation reactions while maintaining sample homogeneity.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless Steel (316L) | Corrosion-resistant environments |

| Voltage Options | 110V, 220V, 380V | Global lab power systems |

| Automatic Grade | Semi-Automatic | User-controlled processes with safety locks |

| Pressure Capacity | Up to 200 bar (Pro Model) | High-pressure chemical synthesis |

| Stirring Speed | 0–1000 RPM (adjustable) | Uniform mixing in viscous or reactive media |

Adjustable parameters include voltage selection (to match lab infrastructure) and pressure limits (for tailored reaction conditions). The magnetic stirrer speed can be customized for specific viscosity requirements, while the semi-automatic mode allows manual override for critical steps.

With its magnetic stirring system and high-pressure tolerance, this autoclave is ideal for optimizing hydrogenation, polymerization, or catalytic reactions. Its multi-voltage compatibility ensures seamless integration into any lab, while the semi-automatic design balances safety and user control.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Pressure Capacity | 100 bar | 150 bar (+50%) | 200 bar (+100%)* |

| Stirring Speed | 0–500 RPM | 0–800 RPM | 0–1000 RPM |

| Automation Level | Semi-Automatic | Semi-Automatic w/ PID | Fully Automated |

| Certifications | CE | CE + ASTM E138 | CE + ASTM E138 + ISO |

Technical Breakthroughs:

Optimal Version Selection:

*Compared to industry benchmarks at 150 bar.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Pressure Capacity | Hazardous chemical synthesis | Industry Standard: 20 MPa (ISO 2852) Our Base: 30 MPa▲ Our Advanced: 50 MPa▲▲▲ | Handles extreme reactions safely (e.g., hydrogenation) Advanced: ▲▲▲ for high-pressure R&D | Base/Advanced: Higher cost vs. standard lab reactors |

| Voltage Compatibility | Global lab setups | Industry Standard: Single-voltage (e.g., 220V) Our Base/Advanced: 110V/220V/380V▲▲ | Universal deployment across regions (e.g., US/EU/Asia labs) | Requires voltage adapter for non-native systems |

| Automation Level | Repetitive batch processing | Industry Standard: Manual controls Our Base: Semi-automatic▲ Advanced: Fully automatic▲▲▲ | Base: PLC-controlled parameters (IEC 61131-3) Advanced: ▲▲▲ for无人 operation | Advanced: Requires training and higher maintenance |

| Material Construction | Corrosive environment use | Industry Standard: 304 stainless steel (ASTM A269) Our Base/Advanced: 316L▲▲ (ASTM A276) | Advanced: ▲▲ Resists nitric/organic acids (e.g., hydrogenation catalysts) | Base/Advanced: Heavier than standard materials |

| Stirrer Performance | High-viscosity reactions | Industry Standard: 0-800 RPM (ISO 5211) Our Base: 0-1200 RPM▲ Advanced: 0-1500 RPM▲▲▲ | Advanced: ▲▲▲ Ensures thorough mixing in viscous slurries | Advanced: Increased energy consumption |

| Safety Features | Emergency shutdown scenarios | Industry Standard: Basic pressure/temperature alarms Our Base: Dual sensor redundancy▲ Advanced: Auto-purge + remote monitoring▲▲▲ | Advanced: ▲▲▲ Prevents overpressure (≤0.5% error via ISO 16047) | Base/Advanced: Adds complexity to setup流程 |

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Pharmaceutical Research Lab

"We’ve been using the Advanced Model of this autoclave for 5 months now, and it has significantly improved our hydrogenation workflow. The semi-automatic PID control ensures consistent temperature and pressure, while the 316L stainless steel construction holds up perfectly against aggressive solvents. We run multiple batch reactions weekly, and the dual-pressure safety valve gives us peace of mind during overnight runs. Setup was straightforward thanks to the 220V compatibility—no converter needed in our Berlin lab."Purchase Date: February 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Prof. David Kim - University Materials Science Lab

"This autoclave is a game-changer for small-scale R&D. We opted for the Base Model due to budget constraints, but it still delivers exceptional performance for hydrogenation under 100 bar. The magnetic stirrer eliminates hotspots in our catalytic reactions, and the compact footprint fits perfectly in our shared lab space. Cleaning is simple—just a mild acid wash and rinse. After 8 months of use, zero signs of corrosion or wear."Purchase Date: June 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Dr. Anika Patel - Industrial R&D Facility

"The Pro Model we purchased handles high-throughput hydrogenation with ease. The fully automated system integrates well with our data logging software, and stirring up to 1000 RPM keeps viscous slurries homogeneous. One minor issue: the interface takes time to learn, so new lab members require training. But once mastered, it's incredibly efficient. Safety certifications (ISO + ASTM) were crucial for our audit compliance."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dr. James Wu - Organic Synthesis Lab

"We needed a reactor that could handle both batch and continuous hydrogenation, and this autoclave delivers. The voltage flexibility (380V) allowed seamless integration into our existing power system without modifications. We’ve customized the stirring speed for high-viscosity intermediates, and the real-time pressure monitoring has prevented two potential over-pressurization incidents. After 6 months, it remains leak-free and stable."Purchase Date: September 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Lena Fischer - Catalysis Research Group

"As someone who’s worked with multiple high-pressure reactors, I can confidently say this one stands out. The 50 bar precision control (on our customized Base Model) is ideal for screening catalysts. The detachable magnetic stirrer makes cleaning between runs fast and foolproof. Plus, the FDA and ISO 22000 compliance means we can use it for pre-clinical compound synthesis. A solid investment for any serious lab."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Thomas Reed - Senior Lab Systems Engineer

"For labs conducting hydrogenation under pressure, this autoclave series offers best-in-class material durability and operational safety. The use of 316L stainless steel exceeds typical 304-grade reactors, especially in acidic or hydrogen-rich environments. I particularly recommend the Advanced Model for industrial R&D teams needing programmable control and mid-range pressure tolerance."

Dr. Rebecca Liu - Process Safety Advisor

"The inclusion of dual-pressure safety valves, automatic shutdown, and seamless welds makes this autoclave one of the safest I’ve evaluated for high-pressure chemistry. Its semi-automatic design strikes the right balance between user control and risk mitigation—ideal for teaching labs and GMP environments alike."

Posted: 2 days ago

"Purchased the Base Model for pilot-scale hydrogenation. Installation was plug-and-play with our 110V system. The stirring uniformity has improved reaction yields by ~15%. Very satisfied with the build quality."

Posted: 1 week ago

"Switched from a manual reactor to the Pro Model. Full automation has reduced operator error and increased reproducibility. The remote monitoring feature is a huge plus for compliance tracking."

Posted: 3 weeks ago

"Stirring and pressure control are excellent. Took about a week to fully train grad students on the interface. Otherwise, flawless operation under 150 bar conditions."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.