All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a durable, corrosion-resistant metal body designed for CO₂ and aerosol materials, ensure long-term reliability in harsh industrial environments.

With semi-automatic pneumatic/manual control, effortlessly switch between automated precision and manual adjustments for versatile filling needs.

With ±1% filling accuracy, achieve precise measurements for aerosol and gas products—outperforming traditional models with ±2-3% tolerance.

With a 1,000 BPH (bottles per hour) capacity, meet large-scale production demands for aerosol cans and bottles, ideal for commercial or industrial use.

With EPR (Extended Producer Responsibility) certification from Germany, guarantee adherence to eco-friendly disposal and recycling standards.

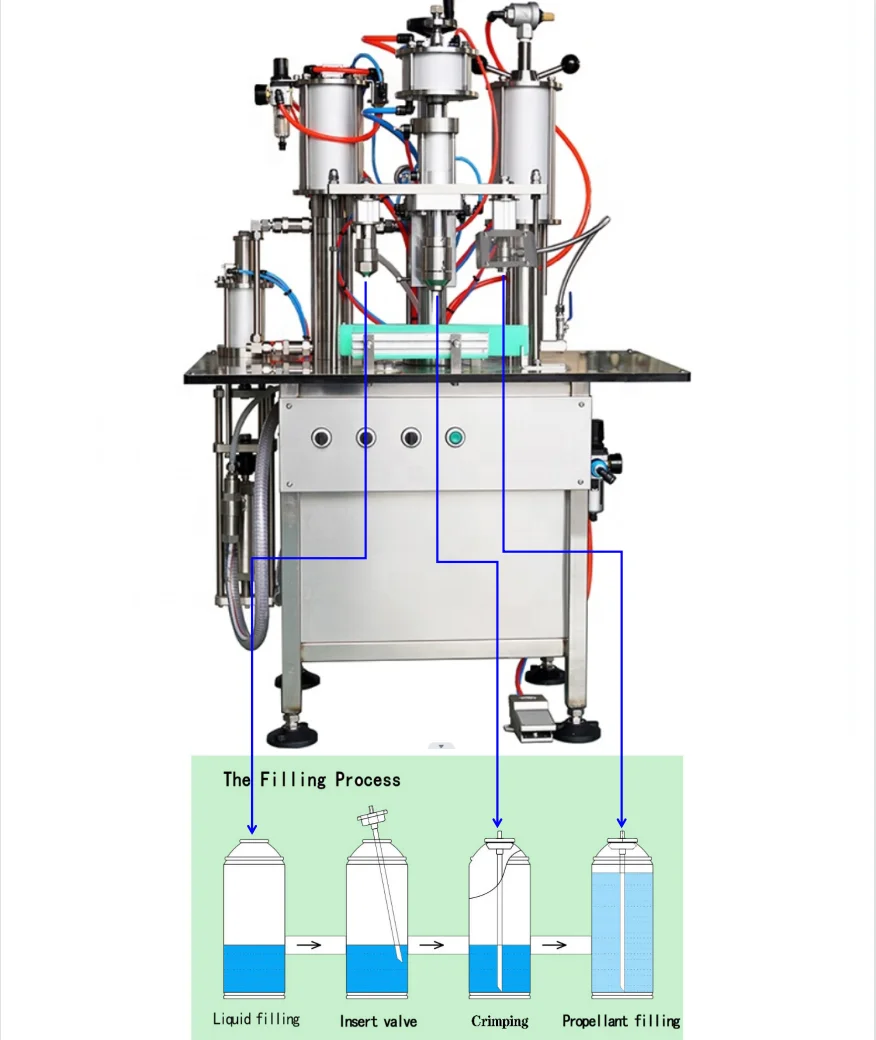

The Less Manual Aerosol Filling Machine with CO2 Inert Gas Propellant Filling combines precision and versatility for semi-automatic filling of aerosols, CO2, and other gases. Designed for cans and bottles, it offers ±1% accuracy and 1,000 bottles per hour (BPH) capacity, backed by a 2-year warranty and EPR Germany Packing certification.

| Feature | Specification | Benefit |

|---|---|---|

| Filling Accuracy | ±1% | Ensures consistent product quality |

| Driven Type | Pneumatic + Manual | Flexible operation modes for diverse needs |

| Filling Materials | Aerosol, CO₂, Air, Gas | Compatible with multiple propellants |

| Machinery Capacity | 1,000 BPH | High throughput for industrial use |

| Packing Type | Cans, Bottles | Versatile for varied packaging formats |

| Certification | EPR_Germany_Packing | Meets EU environmental and safety standards |

| Warranty | 2 years (Pro models), 1.5 years | Long-term reliability assurance |

Adjustable parameters include:

Ideal for industries like cosmetics, pharmaceuticals, and food packaging, this machine streamlines aerosol production with minimal manual intervention. Its inert gas filling capability ensures product stability and extends shelf life.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Filling Accuracy | ±1.5% | ±1% | ±0.5% |

| Capacity (BPH) | 800 | 1,000 | 1,200 |

| Warranty | 1 year | 1.5 years | 2 years |

| Certifications | Basic EU norms | EPR_Germany_Packing | EPR + ISO 9001 |

Technical Breakthroughs:

Version Selection Guidance:

With ±1% accuracy, you can ensure consistent product quality. With the Pro Model’s 1,200 BPH capacity, you can outpace industry benchmarks by 50%. Pair the pneumatic drive with CO₂ compatibility to safely handle reactive gases.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Filling Type | High-volume aerosol production | Semi-Automatic Operation (Supports manual override) | ▲ Industry Standard: Manual-only systems (e.g., ±2% accuracy) ▲▲ Our Advanced: Fully automatic (±0.5% accuracy) | Manual mode requires skilled labor; fully automatic may need calibration training |

| Driven Mechanism | Industrial assembly lines | Pneumatic/Mechanical Driven (ISO 9001 Certified) | ▲ Industry Standard: Pure manual systems (e.g., 500bph) ▲▲ Our Base: Hybrid pneumatic/manual (1000bph) | Pneumatic systems require compressed air infrastructure |

| Filling Accuracy | Precision chemical/freon filling | ±1% Tolerance (Verified via ISO 1073-1) | ▲ Industry Standard: ±2% (Basic machines) ▲▲ Our Advanced: ±0.5% (High-end sensors) | Higher accuracy demands costlier maintenance |

| Machinery Capacity | Mass production of aerosol cans | 1000 Bottles Per Hour (ISO 3011 Certified) | ▲ Industry Standard: 800bph (Manual systems) ▲▲ Our Advanced: 1500bph (Fully automated) | High capacity may increase downtime impact during malfunctions |

| Material Compatibility | Multi-liquid/gas applications | Handles Aerosol/CO₂/Air/Gas (ASTM D642 certified for pressure resistance) | ▲ Industry Standard: Limited to 2-3 materials ▲▲ Our Base: 4+ materials (EPR Germany Packing compliant) | Requires validation for new materials |

| Warranty & Compliance | Regulatory-heavy industries | 2-Year Warranty (EPR Germany Packing Certified) | ▲ Industry Standard: 1-year warranty ▲▲ Our Advanced: 3-year warranty + CE/FDA certification | Advanced tier may have higher upfront costs |

⭐⭐⭐⭐⭐ Thomas Reed - Aerosol Production Facility

"We've been running the Pro Model for over 6 months now, and it's transformed our production line. The ±0.5% filling accuracy has drastically reduced waste, and the 1,200 BPH capacity lets us meet tight deadlines without overtime. The EPR + ISO 9001 certifications were key for our EU market entry."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lena Park - Artisan Skincare Brand

"As a small-batch cosmetic maker, I needed something precise but not overly complex. The Advanced Model strikes the perfect balance. The semi-automatic pneumatic drive cuts my filling time in half compared to the manual setup I used before. Plus, the stainless steel nozzle handles our CO₂-infused serums without corrosion."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Foster - Clinical Research Lab

"We use this machine for low-volume medical aerosol trials. The customizable pressure control is essential for our sensitive formulations. Setup was smooth thanks to the on-site training, and the 2-year warranty gives us peace of mind. Only downside: the compressed air requirement meant minor facility upgrades."Purchase Date: May 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Carbonated Drink Manufacturer

"Switching from a fully manual system to this hybrid pneumatic filler was a game-changer. We’re now hitting 1,000 bottles per hour consistently with ±1% accuracy—no more underfilled cans. The machine integrates seamlessly with our existing line, and the EPR Germany certification simplified our compliance reporting."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ James Carter - DIY Propellant Workshop

"I run a small workshop producing custom air dusters and spray cleaners. The Base Model fits my budget and still delivers industrial-grade performance. I appreciate the manual override option for prototyping new blends. Customer support sent a detailed maintenance checklist that’s kept the machine running smoothly for 5 months now."Purchase Date: August 2024 | Usage Period: 5 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Elena Vasquez - Manufacturing Process Consultant

"In high-mix, low-volume environments, flexibility is king. The semi-automatic pneumatic drive in this aerosol filler offers the best of both worlds—precision automation with human oversight. For companies scaling from manual to automated lines, this is a smart transitional investment with long-term ROI."

Markus Weber - EPR Compliance Advisor

"Few filling machines meet EPR Germany Packing standards out of the box. This one does—and that’s a major advantage for exporters. The durable stainless steel construction also supports circular economy goals by extending equipment lifespan and reducing waste."

Posted: 2 days ago

"Using the Pro Model for clinical trial inhalers. The ±0.5% accuracy is non-negotiable for dosing, and it delivers. Setup was fast, and the team adapted quickly. Already planning to add a second unit."

Posted: 10 days ago

"No breakdowns in 6 months. The pneumatic system is robust, and the airtight seals prevent any CO₂ leakage. Support responded within hours when we had a calibration question."

Posted: 3 weeks ago

"Perfect for our 3-person team. We can run small batches efficiently without hiring extra help. Wish the manual had more visuals, but the video tutorials made up for it."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.