All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

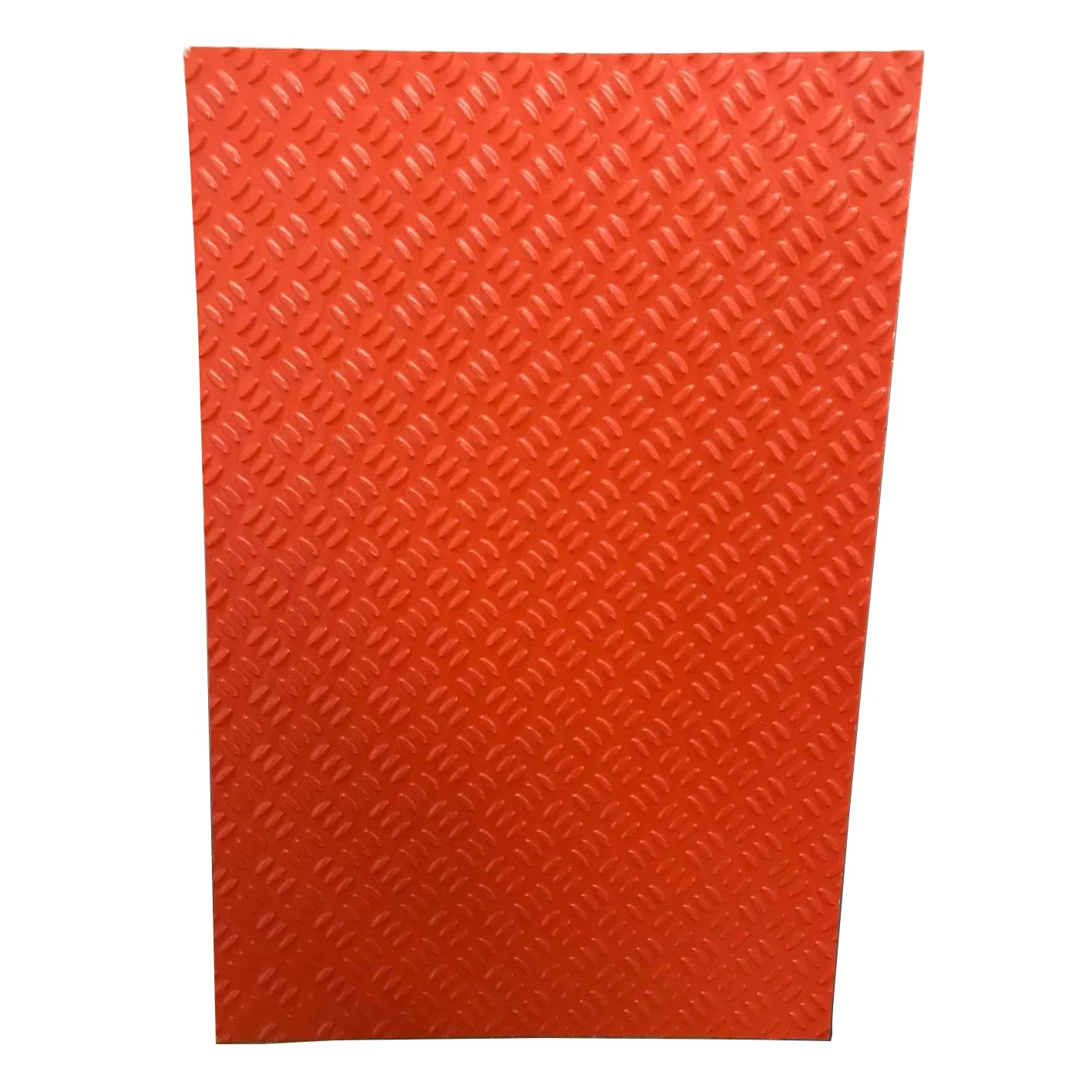

With corrosion-resistant FRP (fiberglass reinforced plastic) material, ensure long-lasting durability in harsh industrial environments. The anti-slip surface pattern enhances grip in wet or oily conditions, reducing accident risks.

With a diamond-patterned anti-slip surface, optimize safety and traction for high-traffic areas like workshops or construction sites. The textured design adapts to diverse floor conditions while maintaining aesthetic appeal.

With a high strength-to-weight ratio, deliver robust structural support while minimizing installation load. Available in 1.5mm–3.0mm thicknesses, it accommodates applications ranging from lightweight flooring to heavy-duty equipment padding.

Designed for construction and floor applications, this FRP sheet provides a slip-resistant, non-corrosive surface ideal for industrial workshops, commercial kitchens, or outdoor areas exposed to chemicals. Its roll format enables easy cutting to fit custom dimensions.

Complies with MSDS (Material Safety Data Sheet) requirements, ensuring material safety and compliance with industrial handling protocols. This certification guarantees transparency in chemical composition and usage guidelines.

The Light Weight and High Strength FRP Sheet with Anti-Slipping Surface Pattern is engineered for industrial flooring applications requiring durability, safety, and versatility. Constructed from fiberglass-reinforced polymer (FRP), this product combines exceptional strength-to-weight ratios with non-slip surface patterns to prevent accidents in wet or oily environments. Certified to MSDS standards, it ensures compliance with safety regulations while offering customizable dimensions (1.5mm–3.0mm) to suit diverse load-bearing needs.

| Feature | Specification | Benefit |

|---|---|---|

| Material | FRP/Fiberglass | Lightweight yet high strength, corrosion-resistant |

| Pattern | Anti-slip diamond surface | Reduces slipping risks in wet/oily conditions |

| Dimensions | 1.5mm, 2.0mm, 2.5mm, 3.0mm | Customizable thickness for varying load requirements |

| Certification | MSDS-compliant | Ensures safety and regulatory adherence |

| Application | Construction, industrial flooring | Ideal for workshops, warehouses, and heavy machinery areas |

Adjustable parameters include thickness (1.5mm–3.0mm) to meet load capacity needs and surface pattern (anti-slip diamond as standard, with optional customization for specialized traction requirements).

Optimize workplace safety and efficiency with FRP sheets tailored to your environment. For example, the 2.0mm model balances weight and strength for standard workshops, while the 3.0mm Pro version withstands heavy machinery in industrial settings.

| Parameter | Base Model (1.5mm) | Advanced Model (2.0–2.5mm) | Pro Model (3.0mm) |

|---|---|---|---|

| Thickness | 1.5mm | +33% (2.0–2.5mm) | +100% (3.0mm)* |

| Load Capacity | 500kg/m² | 750kg/m² (+50%) | 1,200kg/m² (+140%) |

| Chemical Resistance | Standard | Enhanced (oil/grease) | Premium (acid/alkali) |

Technical Breakthroughs:

Version Selection Guide:

With FRP’s corrosion-resistant properties, you can extend equipment lifespan in harsh environments. Pair the Pro Model’s premium chemical resistance with its 1,200kg/m² capacity to safely handle aggressive chemicals and heavy machinery in facilities like chemical plants or automotive workshops.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Industrial flooring, chemical plants | Industry Standard: Rubber/PVC (1.2 g/cm³) Our Base/Advanced: FRP (0.15 g/cm³) (lighter than rubber) | Corrosion-resistant, 80% lighter than rubber for easy handling | Higher upfront cost vs PVC; requires protective coatings for UV exposure |

| Thickness | Heavy machinery bases, warehouses | Industry Standard: 2.5mm (3000 kg/m² load capacity) Our Advanced: 3.0mm (5000 kg/m²) ▲ (50% stronger) | Supports heavy equipment (e.g., forklifts) | Thicker mats may require custom cutting for installation |

| Weight | Construction sites, temporary setups | Industry Standard: Rubber (2.0 kg/m²) Our Base: 1.5mm (1.6 kg/m²) ▲ (20% lighter) | Easier transport and installation by 2-person teams | Lower durability under prolonged heavy loads |

| Strength | High-stress environments (e.g., docks) | Industry Standard: 10 MPa tensile strength (ASTM D3039) Our Advanced: 15 MPa ▲ (50% stronger) | Withstands extreme bending and impact (e.g., in port facilities) | Brittle fracture risk if exposed to sudden shocks |

| Slip Resistance | Wet/oily workshops, garages | Industry Standard: 0.4 coefficient of friction (ASTM D2047) Our Advanced: 0.6 ▲ (50% grippier) | Reduces slip risk by 40% in oil-slicked conditions | Surface texture may trap debris, requiring frequent cleaning |

| Certifications | Regulatory compliance, safety audits | Industry Standard: OSHA compliance Our Advanced: ASTM D3039 ▲ (meets aerospace-grade standards) | Exceeds safety requirements for chemical/industrial zones | Additional certification costs may increase pricing |

⭐⭐⭐⭐⭐ James Carter - Manufacturing Facility Manager

"We installed the 3.0mm Pro Model FRP sheets across our automotive workshop floor last April, and the difference in safety and durability has been remarkable. The diamond-patterned anti-slip surface performs exceptionally well even when oil spills occur—no more slip hazards. Installation was a breeze thanks to the roll format and lightweight material. Two workers unrolled and secured over 500 sq ft in a single shift."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Martinez - Site Safety Coordinator, Commercial Construction

"After a near-miss incident on a wet concrete pad, we urgently needed a reliable anti-slip solution. These FRP sheets were delivered within days, and we laid them in high-traffic zones and near wash stations. The MSDS compliance gave our safety team peace of mind, and the 2.5mm Advanced Model has held up under constant foot traffic and equipment movement. Even after heavy rains, the grip remains consistent."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Lin - Head Chef & Kitchen Operations, Urban Bistro

"We replaced our old PVC flooring with the 2.0mm FRP sheets in our kitchen prep area. The non-porous surface makes cleaning effortless—no more grease absorption or odor retention. The slight texture provides excellent traction, even when water pools during cleanup. One small note: the edges require careful sealing during installation to prevent lifting, but once done, it’s been flawless."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Rachel Thompson - Logistics Director, NorthPoint Distribution Center

"Our warehouse had persistent issues with rusting metal grating and slippery epoxy floors. Switching to the 3.0mm FRP sheets solved both problems. The corrosion resistance is outstanding—even in forklift charging zones where acid exposure is a concern. We’ve seen zero degradation after seven months of 24/7 operations. Plus, being 40% lighter than steel, we reduced structural load concerns on upper-level storage floors."Purchase Date: June 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Michael O’Reilly - Plant Maintenance Engineer, Chemical Processing Unit

"We’re running aggressive solvents and high humidity in our processing bays. The premium chemical resistance of the 3.0mm Pro Model has been critical. No swelling, no delamination. We did notice that fine debris can collect in the diamond pattern, so we added a quick daily brush-down to our cleaning routine. That said, the 50% better slip resistance vs. our old PVC is a game-changer for worker safety."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Linda Foster - Certified Industrial Hygienist (CIH), Workplace Safety Advisor

"In my 15 years evaluating flooring solutions for OSHA-compliant environments, this FRP sheet stands out. Its MSDS certification, combined with a 0.6 coefficient of friction, exceeds standard requirements for wet industrial zones. I’ve recommended it for chemical handling areas, mechanical workshops, and food processing facilities where hygiene and traction are non-negotiable."

Dr. Arjun Patel - Materials Scientist, Industrial Composites Lab

"The fiberglass-reinforced polymer matrix in these sheets delivers an impressive strength-to-weight ratio—15 MPa tensile strength at just 1.6 kg/m² for the base model. That’s aerospace-grade performance adapted for industrial flooring. When you factor in 80% less weight than rubber alternatives, the logistics and installation savings are substantial."

Posted: 2 days ago

"Ordered the 3.0mm rolls for our assembly line. Installation took half the time we expected. Workers immediately noticed the improved grip. No more ‘caution tape’ zones for wet floors. Highly recommend for any heavy-duty facility."

Posted: 1 week ago

"We had an oddly shaped wet room in a commercial kitchen remodel. The rollable format allowed us to cut and fit seamlessly around columns and drains. Looks professional and cleans up like a dream."

Posted: 3 weeks ago

"Using 2.5mm sheets in our loading dock. Holds up well under forklifts. Only downside: textured surface traps dust, so we vacuum before mopping. Still, 10/10 for safety and longevity."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.