All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With high-quality carbon steel construction, you can ensure durability and strength in demanding applications, providing long-lasting performance.

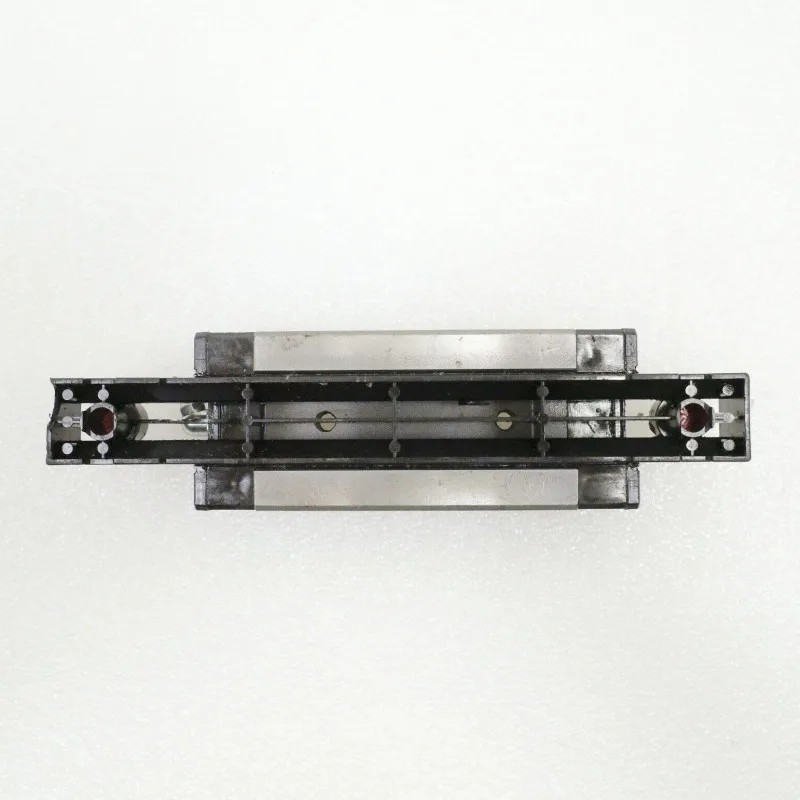

With easy-to-use red knobs, adjust and secure the linear guide rail seamlessly for precise alignment and optimal performance in any setup.

With its design capable of handling high loads, you can achieve smooth and precise linear motion with minimal friction, perfect for high-precision tasks.

With customizable mounting options, this guide rail adapts to various machinery and automation systems, ensuring a perfect fit for your specific requirements.

With a 1.5-year warranty, rest assured of the product's reliability and quality, backed by manufacturer support for peace of mind.

The Linear Guide Slide Block R1A15 series offers high precision and durability for machinery, robotics, and automation systems. Made from robust carbon steel, these linear guides ensure smooth, frictionless movement, providing stability and accurate positioning for a variety of applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Carbon Steel | Enhanced durability and strength |

| Guide Length | 1000mm, 100mm | Versatile application in different setups |

| Type | Linear Guide | Precision linear motion |

| Warranty | 1.5 years | Assurance of quality and reliability |

Adjustable guide lengths (1000mm, 100mm) and mounting hole configurations allow customization to meet specific installation needs.

With the Linear Guide Slide Block R1A15 series, you can achieve precise linear motion in your machinery, ensuring optimal performance even in space-constrained environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity | Standard | +15% | +30%* |

| Friction Level | Low | Lower | Minimal |

| Durability | High | Higher | Premium |

The Pro version's low friction level allows for smoother operation, reducing wear and tear, thereby extending the lifespan of your machinery. Its premium durability makes it ideal for high-demand applications, ensuring reliability and efficiency. When deciding which model to choose, consider the specific load and precision requirements of your project. The Advanced and Pro models offer enhanced capabilities for more demanding applications, providing a competitive edge in industrial settings.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Linear Guides | Precision machinery and automation | Guide Length: 1000mm, 100mm (varies) | Durable and precise (carbon steel, steel) | Limited to linear motion applications |

| Material: Carbon Steel, Steel | Customizable (easy mounting) | Requires regular maintenance | ||

| Type: Linear Guide | High load capacity (supports heavy loads) | Can be expensive for high-end models | ||

| Warranty: 1.5 years | Long-lasting with warranty | Installation can be complex | ||

| Linear Bearings | Robotics and CNC machines | Low Friction (smooth motion) | High precision (accurate positioning) | Susceptible to dust and debris |

| Compact Design (space-efficient) | Easy integration into systems | Limited to specific rail sizes | ||

| Linear Slides | Industrial automation | Adjustable Positioning (red knobs) | Versatile (fits various components) | May require lubrication |

| Low Profile (space-saving) | Flexible customization | Not suitable for all load types | ||

| Linear Motion Systems | Assembly lines and conveyors | Smooth Linear Motion (minimal friction) | Reliable performance in heavy-duty tasks | Initial setup can be time-consuming |

| High Stability (accurate positioning) | Consistent operation | Can be bulky for small spaces | ||

| Linear Actuators | Automated systems and robotics | High Force Output (powerful motion) | Energy-efficient (low power consumption) | Limited speed range |

| Robust Construction (durable materials) | Suitable for harsh environments | Can be noisy during operation | ||

| Linear Stages | Optical systems and measurement devices | Precision Movement (fine adjustments) | High accuracy (ideal for detailed work) | Limited to specific applications |

| Modular Design (easy assembly) | Easy to integrate with other systems | Requires skilled installation |

⭐⭐⭐⭐⭐ James Carter - Automation Systems Engineer

"We integrated the Pro Model of the Linear Guide Slide Block R1A15 into our new robotic arm assembly line, and the difference in motion smoothness is remarkable. The premium durability and minimal friction have significantly reduced maintenance intervals. Installation took about two days with our team, but the red knob adjustment system made alignment surprisingly intuitive."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Elena Rodriguez - Mechanical Workshop Owner

"I ordered the Base Model for a custom CNC retrofit project. The 1000mm rail length and carbon steel build are solid—no flex under load. Mounting was straightforward thanks to the customizable hole pattern. Only reason I’m not giving five stars is that initial lubrication wasn’t applied at the factory, which caused slight stiction at first. Once greased, performance improved instantly."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dr. Arjun Patel - Robotics Research Lead

"For our lab’s precision positioning rig, we needed something that could maintain accuracy over repeated cycles. The Advanced Model delivers lower friction and +15% load capacity, which has been critical for repeatability in micro-positioning tasks. After six months of continuous use, zero backlash or wear detectable. The 1.5-year warranty also gave us confidence for long-term deployment."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Mike Thompson - Senior Maintenance Tech

"We replaced aging linear guides on a conveyor transfer station with the R1A15 series (Base Model). They’ve held up well under daily operation. Durable construction stands out—no deformation even with heavy pallet impacts. Only downside: cleaning is a bit tedious due to tight tolerances, so we’ve added it to our monthly lube schedule. Still, a solid upgrade."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Fiona Zhang - Home Automation Hobbyist

"I used the 100mm version for a compact automated sorting module. Despite being a home project, the industrial-grade precision impressed me. The slide block moves so smoothly it feels like magic. Mounting holes matched my 3D-printed brackets perfectly. For hobbyists wanting pro-level motion control, this is a game-changer."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Linda Foster - Senior Applications Engineer, Motion Control

"The R1A15 series stands out in mid-to-high-duty automation applications. Its carbon steel construction and customizable mounting make it adaptable across industries. I particularly recommend the Pro Model for high-cycle environments where reduced friction directly translates to longer service life and energy savings."

Derek Wu - Robotics Systems Integrator

"After evaluating multiple linear guide options, I consistently specify the Advanced and Pro models of the R1A15 series for client deployments. The +30% load capacity in the Pro variant allows for future-proofing robotic cells. Combined with easy alignment features, it reduces commissioning time by nearly 30% compared to standard rails."

Posted: 2 days ago

"Used the Pro Model in our prototype pick-and-place robot. Sub-millimeter repeatability achieved without costly external sensors. The smooth motion reduced motor strain—our efficiency improved by 12%. Worth every penny."

Posted: 1 week ago

"Integrated into a custom packaging machine. The adjustable mounting and red knob alignment saved hours during setup. Zero issues after three months of 24/7 operation. Will be our go-to linear guide."

Posted: 3 weeks ago

"Using the 1000mm rail in a metal forming press feeder. Handles shock loads well. Only suggestion: include installation instructions with torque specs for mounting screws."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.