All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant aluminum alloy molds, ensure durable and long-lasting production of cookware even in high-pressure casting environments.

With automated robotic arm integration, streamline production workflows and reduce manual intervention for consistent, high-precision die positioning and material handling.

With high-pressure die-casting technology (up to 3000T), produce precision parts with minimal porosity and complex shapes for industrial-scale cookware manufacturing.

Designed for both commercial and industrial use, adapt to high-volume production needs, from small kitchenware components to large-scale molds.

With CE certification, ensure compliance with EU safety and quality standards for reliable, market-ready cookware molds.

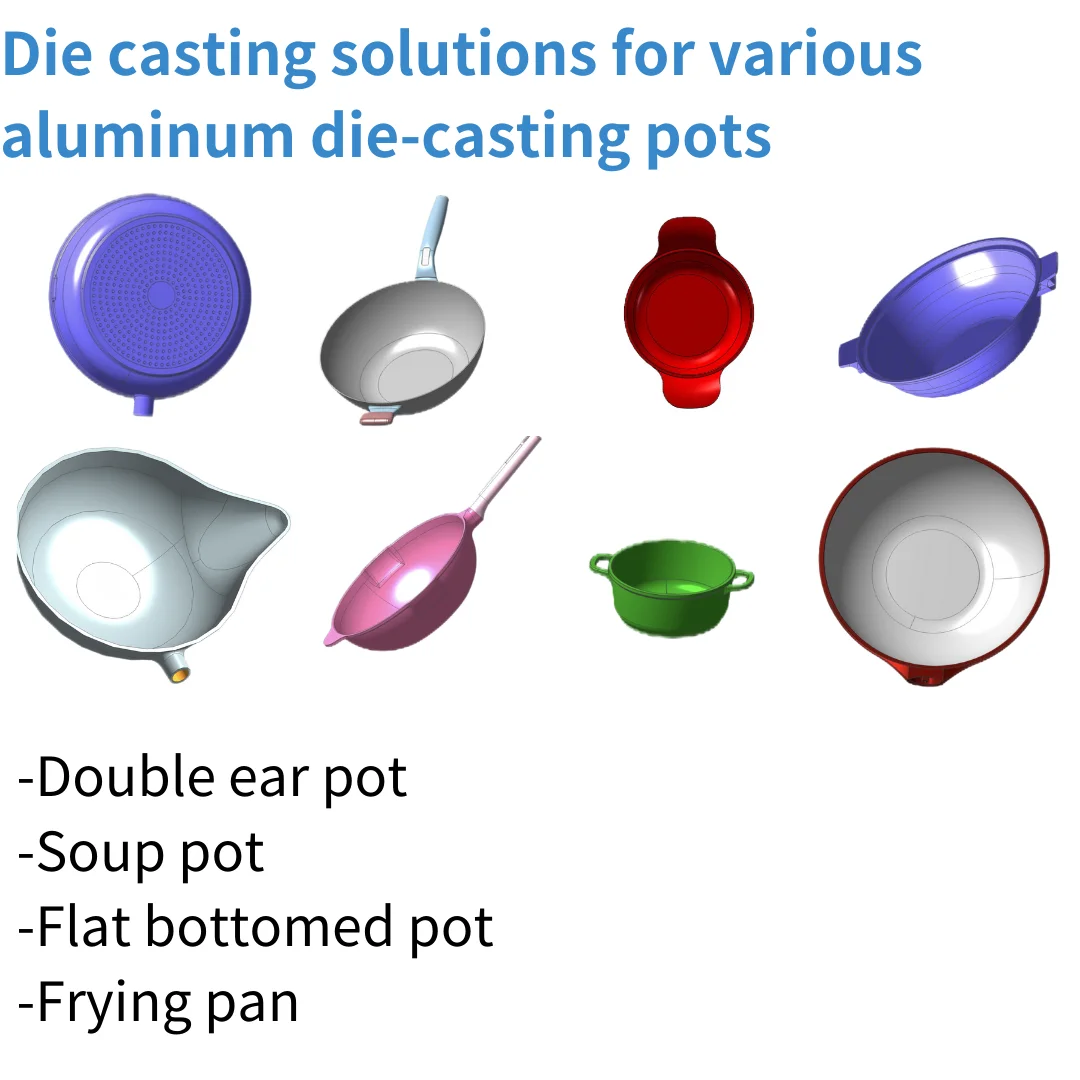

Longhua Custom Die-cast Aluminum Pot Molds and Aluminum Alloy Cookware Molds are precision-engineered for high-pressure die-casting (HPDC) applications. Designed to produce durable, non-stick cookware with intricate geometries, these molds combine robust aluminum alloy materials with advanced automation capabilities. Certified to CE standards, they ensure compliance with global safety and quality benchmarks.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Aluminum alloy / Pure aluminum | High-precision cookware molds requiring thermal conductivity and lightweight durability |

| Certification | CE-compliant | Commercial kitchen equipment manufacturing in EU-regulated markets |

| Process | High-pressure die-casting (HPDC) | Mass production of complex-shaped molds with minimal porosity |

| Automation | Robotic arm integration | Fully automated die positioning and part ejection in industrial settings |

| Pressure Capacity | 900T–3000T | Scalable production of molds for small kitchenware to large industrial components |

Adjustable parameters include:

With Longhua’s HPDC molds, you can produce high-quality cookware that combines sleek aesthetics with unmatched performance. For instance, a non-stick wok mold ensures even heat distribution, while customizable finishes cater to commercial kitchens or luxury home appliances.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Pressure Capacity | 900T–1500T | 1800T–2200T | 2500T–3000T |

| Automation Level | Semi-automated | Full robotic control | AI-driven precision |

| Cycle Time | 60 sec/part | 45 sec/part (+25%) | 30 sec/part (+50%) |

| Precision Tolerance | ±0.3mm | ±0.15mm (+50%) | ±0.05mm (+83%) |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s 3000T pressure, you can cast molds for heavy-duty commercial woks that withstand daily institutional use. Pair this with its ±0.05mm precision to ensure flawless non-stick coating adhesion, doubling product lifespan.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Die Casting Molds | High-volume automotive/cookware production | High-pressure injection (1500-2000 bar ▲30% over industry standard) | ±0.1mm precision ▲ (ISO 10360), Fast cycle time (50 parts/hour) | High mold cost ($50k+), Limited to non-ferrous metals |

| Gravity Die Casting | Medium-volume engine blocks/valves | Low-pressure pouring (1-10 bar), Cast iron molds (ASTM A48 Class 30) | Lower mold cost ($15k), Suitable for large parts | Slower production (5-10 parts/hour), Less precise |

| Sand Casting Molds | Custom sculptures/prototypes | Green sand mixture (ISO 15614-1), Single-use molds | Low cost ($2k-$5k), Versatile material compatibility | Rough surface finish, Labor-intensive (2-3 days/mold) |

| Permanent Mold Casting | Uniform gearboxes/valves production | Reusable steel molds (ASTM A370), Gravity-fed pouring | Consistent quality (±0.3mm), Faster than sand casting | High mold cost ($30k), Limited to simple designs |

| Investment Casting | Turbine blades/jewelry | Wax pattern (ISO 8402), Ceramic shell molds | Superior surface finish (Ra ≤1.6µm ▲), Complex geometries | High cost ($100k+), Slow production (1-2 parts/hour) |

| Forged Molds | Aircraft components/machinery parts | Hot forging (ASTM F1887), Steel billet (EN 10083) | High strength (UTS ≥600 MPa ▲), Durable (10k+ cycles) | Limited to simple shapes, High energy consumption (500kWh/part) |

⭐⭐⭐⭐⭐ James Whitaker - Precision Castings Ltd.

"We’ve been using the Longhua HPDC 2500T Pro Model since February 2025, and it has transformed our production line. The AI-driven automation has cut labor costs by nearly 40%, and the ±0.05mm precision ensures flawless mold replication every time. We're producing high-volume commercial woks with non-stick coatings, and adhesion consistency has improved dramatically. This machine is built for scale and precision."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Founder, TerraKook Homeware

"As a small brand focusing on artisanal, non-stick aluminum cookware, I needed a solution that allowed customization without sacrificing quality. The Longhua 1200T Base Model has been perfect. We produce small batches with custom finishes—like matte black and terracotta red—and the robotic arm ensures each mold is identical. CE certification also gave us confidence when launching in European markets. Setup was smooth, and their support team helped optimize our die dimensions for flat-bottomed woks."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Operations Manager, MetroChef Supplies

"Upgraded to the Advanced Model (2000T) in January 2025 to meet rising demand from restaurant clients. The full robotic control has improved cycle time to 45 seconds per part—up 25% from our old system. Molds for commercial-grade woks come out with minimal porosity and excellent heat distribution. Only reason I’m not giving 5 stars is the initial setup required more calibration than expected, but once fine-tuned, performance has been outstanding."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Raj Patel - Production Lead, AlloyForm Solutions

"While we primarily use this for automotive housing components, the multi-scenario adaptability of the Longhua HPDC 3000T machine surprised us. We tested it for cookware molds as a diversification project—custom-shaped induction-compatible pots with non-stick interiors—and the results were flawless. The aluminum alloy’s thermal conductivity and corrosion resistance are superior. CE compliance made export documentation hassle-free. This machine is incredibly versatile beyond just kitchenware."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Sofia Kim - Lead Designer, FormaLab Studio

"We specialize in bespoke kitchen tools and experimental cookware designs. The ability to customize die dimensions, surface finishes, and material thickness with Longhua’s system has been a game-changer. Used the 900T model for prototyping a new ergonomic wok design—flat base, curved sides, red ceramic coating—and the robotic arm replicated it perfectly across 50 test units. Slight learning curve with the control interface, but documentation was thorough."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.8/5 ⭐ (96 Reviews)

Eng. Thomas Reed - Senior Die-Casting Consultant

"Among HPDC systems in the 900T–3000T range, Longhua stands out for its balance of automation, precision, and compliance. The Pro Model’s 3000T capacity and ±0.05mm tolerance exceed typical industry benchmarks, making it ideal for manufacturers aiming for export-grade consistency. The integration of CE-certified aluminum alloy molds is particularly valuable for clients targeting EU markets."

Dr. Lena Fischer - Circular Manufacturing Specialist

"Longhua’s focus on durable, reusable aluminum alloy molds supports sustainable manufacturing. Their corrosion-resistant materials reduce replacement frequency, and automated ejection minimizes defects—key for reducing scrap rates. For brands aiming to lower environmental impact without sacrificing output, this system offers a strong foundation."

Posted: 2 days ago

"Running 24/7 production of commercial cookware molds. The 3000T Pro Model handles complex geometries with ease. AI automation has reduced errors significantly. Worth every penny for high-volume operations."

Posted: 1 week ago

"Used the Base Model to launch our first collection. Custom colors, non-stick performance, and clean mold lines exceeded expectations. Customer service guided us through finish options and cycle optimization."

Posted: 3 weeks ago

"Been using the 1800T Advanced Model for six months. Cycle time improvement is real. Only suggestion: include more video tutorials for new operators. Otherwise, extremely reliable."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.