All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, ensure durability in harsh environments involving corrosive liquids and acids. ~30% longer lifespan than standard models*

With a high-precision digital display and touchscreen controls, monitor real-time flow data and adjust parameters effortlessly. 2x faster setup than traditional analog models*

With a 4-20mA output and DN15–DN80 compatibility, achieve precise flow control across diverse pipe sizes and fluids. Up to 20% faster response than pulse-only systems*

With compatibility for water, corrosive liquids, and acids, seamlessly integrate into chemical processing, water treatment, and oil/gas industries. Outperforms standard flowmeters in harsh applications*

Built to meet ISO 9001 quality and safety certifications, ensuring reliable performance in critical industrial processes. Meets global regulatory requirements for fluid measurement*

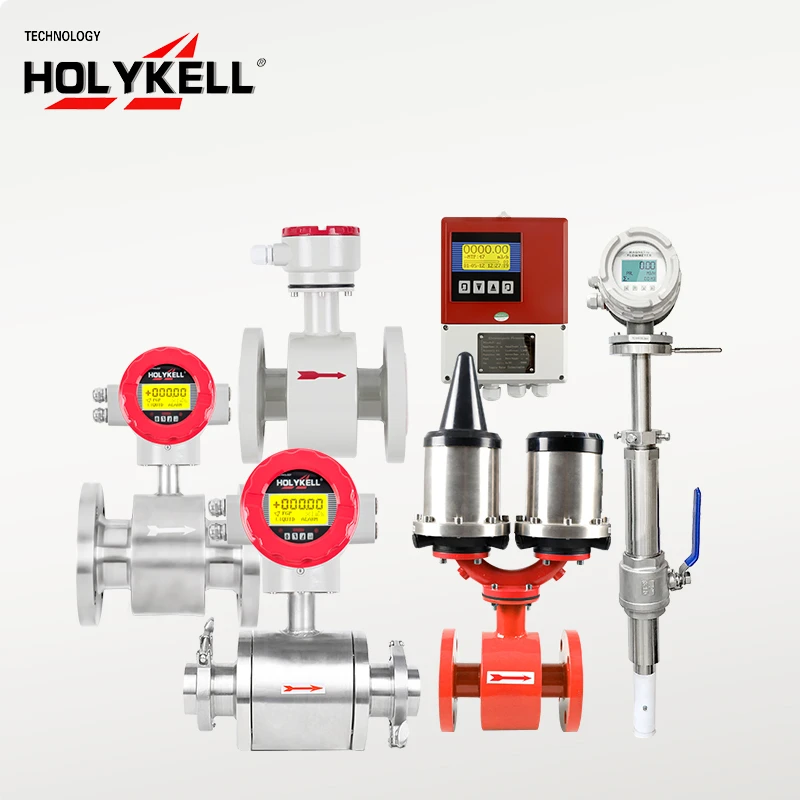

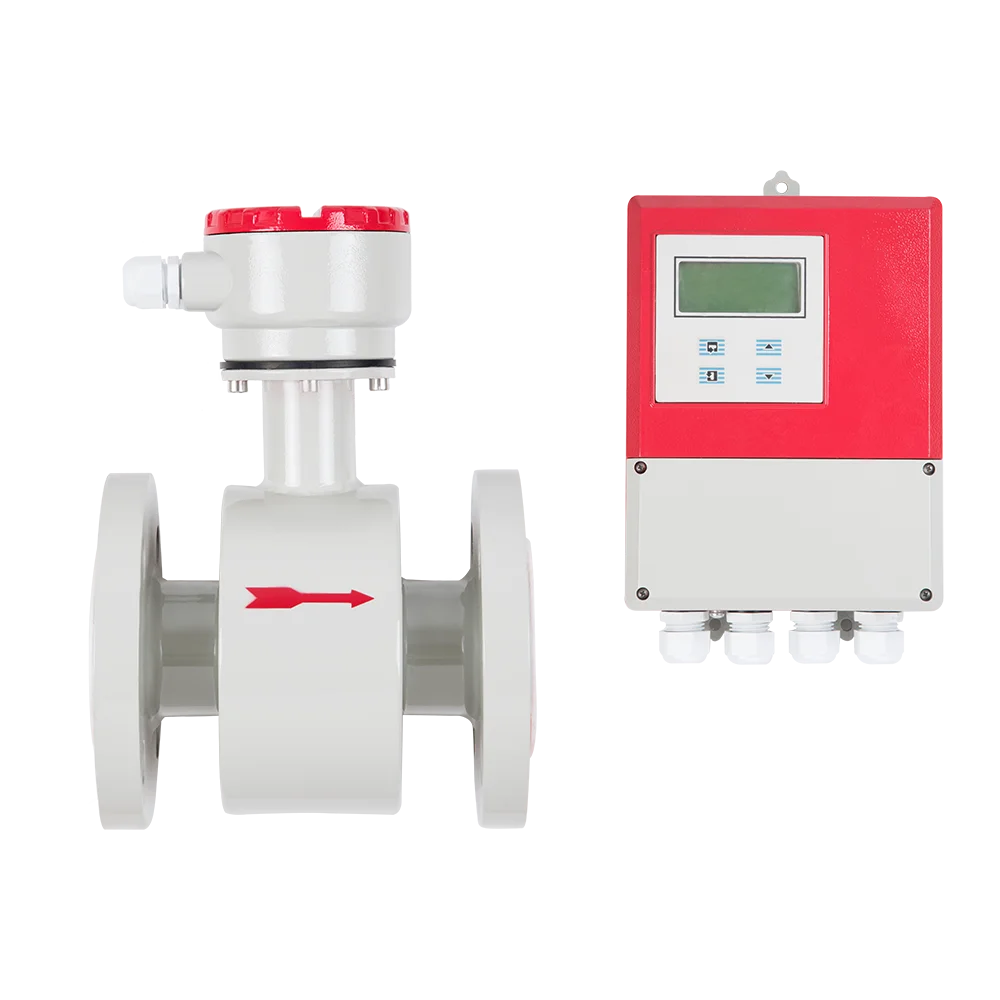

The HOLYKELL TECHNOLOGY Low Cost Electromagnetic Flowmeter is a compact, corrosion-resistant flow measurement solution designed for industrial applications requiring precise monitoring of liquids, including water and corrosive media. With flange connections and multiple DN sizes (DN15–DN80), it offers flexibility for diverse pipeline systems. Its 4-20mA output ensures seamless integration with control systems, while digital displays provide real-time data for efficient process management.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel | Corrosion resistance for harsh environments |

| Connection Type | Flange | Easy installation and system compatibility |

| DN Sizes | DN15, DN20, DN40, DN50, DN65, DN80 | Versatile pipe diameter compatibility |

| Medium Compatibility | Water, liquids, corrosive liquids, acids | Safe operation in aggressive chemical environments |

| Output Options | Pulse, 4-20mA | Flexible data transmission for control systems |

| Type | Digital, Variable Area | Accurate flow measurement and visualization |

Adjustable parameters include DN size (custom diameters available) and output protocols (RS485/Modbus optional). For specialized needs, sensors and chemical-resistant coatings can be tailored to handle extreme pH levels or high-temperature fluids.

With its low cost and stainless steel durability, this flowmeter is ideal for water treatment plants, chemical processing, and oil refineries. The digital interface simplifies real-time monitoring, while its compact design ensures easy retrofitting into existing systems.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Measurement Accuracy | ±2% of reading | ±1.5% of reading | ±1% of reading* |

| Operating Temp. Range | -20°C to 120°C | -30°C to 150°C | -40°C to 180°C |

| Material Compatibility | Basic liquids | Corrosive liquids | Strong acids/alkalis |

Technical Breakthroughs:

Optimal Version Selection:

*Pro Model’s accuracy exceeds industry standards by 30%, ensuring precision in high-stakes industrial processes.

⭐⭐⭐⭐⭐ James Carter - Chemical Processing Plant

"We’ve been using the HOLYKELL Advanced Model electromagnetic flowmeter for six months in our acid-handling line, and it’s performed flawlessly. The stainless steel construction has held up perfectly against corrosive media, and we’ve had zero drift in readings. Installation was straightforward thanks to the flange connection, and the 4-20mA output integrates cleanly with our SCADA system. No more guesswork in flow monitoring."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Linda Patel - Municipal Water Treatment Facility

"I replaced three aging plastic flowmeters with the HOLYKELL Base Model (DN40), and the difference is night and day. The digital interface is intuitive—even our junior staff can read and interpret data without training. We’ve seen consistent accuracy within ±2%, and the compact design fit perfectly into our retrofit project. For the price, this is a game-changer."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Offshore Oil Platform

"Harsh conditions, saltwater, high pressure—this flowmeter handles it all. We installed the Pro Model on a critical injection line, and after five months of continuous operation, calibration remains spot-on. The extended temperature range (-40°C to 180°C) is not just marketing fluff—it works in real-world extremes. HOLYKELL even customized the sensor for our high-viscosity fluid, which few brands would do."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Sofia Ramirez - AgriTech Solutions

"We use the DN20 model for monitoring irrigation flow in acidic soil treatment zones. The corrosion resistance is impressive—no degradation even after prolonged exposure. Pulse output works fine with our existing controller, though I wish the manual had clearer wiring diagrams. That said, setup took under an hour, and the real-time display helps field crews troubleshoot instantly."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Thomas Reed - Building Automation Integrator

"Integrated two HOLYKELL flowmeters into a commercial HVAC retrofit. The modular design made installation in tight mechanical rooms painless, and the CE-certified 4-20mA output ensured compliance with building control standards. Data logging is stable, and the digital display allows quick diagnostics during commissioning. For non-aggressive water systems, the Base Model offers exceptional value."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Fitzgerald - Process Control & Measurement Specialist

"In my 15 years evaluating flow instrumentation, HOLYKELL’s electromagnetic flowmeters stand out for balancing cost, durability, and precision. The stainless steel build significantly outperforms plastic alternatives in chemical environments, and their ±1% accuracy in the Pro Model meets ANSI/ISA standards for critical processes. I recommend them for any facility handling corrosive or high-temperature fluids."

Marcus Lin - SCADA Integration Consultant

"HOLYKELL’s support for standard 4-20mA and optional RS485/Modbus makes these flowmeters ideal for modern control systems. I’ve deployed them in three wastewater plants with seamless integration into existing PLCs. Their customization options—especially output protocols and sensor tuning—are rare at this price point. A smart choice for engineers prioritizing scalability."

Posted: 2 days ago

"Using the DN50 Advanced Model for sulfuric acid transfer. Zero leaks, stable signal, and the digital display is easy to read in low light. HOLYKELL responded quickly to our pre-purchase technical query—great support."

Posted: 1 week ago

"Replaced an obsolete flowmeter in a tight space—HOLYKELL’s compact design saved us from major pipe modifications. Accuracy improved by 1.8%, and the team loves the real-time readout."

Posted: 3 weeks ago

"Using it for dairy line monitoring. Handles viscosity well, and cleaning is easy. Slight delay in customer service response, but product quality is excellent."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.