All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With cross-linked polyethylene (XLPE) insulation and hybrid copper-aluminum conductors, you can achieve high conductivity with cost efficiency compared to all-copper cables*. The aluminum reduces weight while copper ensures optimal power transmission.

With color-coded conductors, you can simplify installation and maintenance by quickly identifying conductors*, reducing errors and saving time during setup.

With a reinforced PE/PVC jacket, you can withstand high underwater pressure and harsh marine environments better than standard cables*, ensuring durability for long-term subsea or outdoor use.

Designed for both building and marine applications, you can deploy this cable in diverse scenarios like terrestrial and underwater power distribution*, making it ideal for residential, commercial, and offshore projects.

With certification to the latest international standards, you can ensure compliance and safety for commercial and residential installations*, meeting rigorous requirements for reliability and environmental protection.

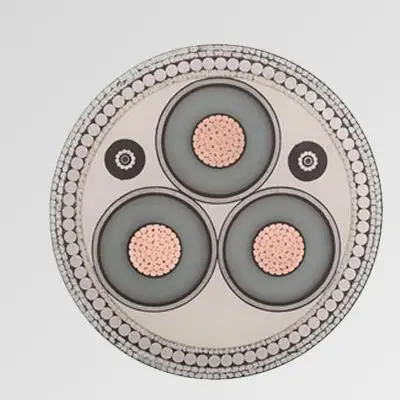

The Low MV Submarine Power Cable is designed for reliable power transmission in marine and building environments. Featuring three XLPE-insulated copper-aluminum conductors and a robust PVC/PE jacket, it combines cost efficiency with high-performance insulation. Its customizable construction meets diverse application needs, from underwater installations to urban infrastructure.

| Feature | Specification | Application Scenario |

|---|---|---|

| Conductor Material | Copper/Aluminum Alloy | Balances conductivity (copper) and weight (aluminum) for marine and building use |

| Insulation Type | Cross-Linked Polyethylene (XLPE) | Ensures high thermal resistance for underwater and high-temperature environments |

| Jacket Material | PE (Polyethylene) + PVC (Polyvinyl Chloride) | Protects against abrasion, UV exposure, and chemical corrosion in marine settings |

| Voltage Rating | Low Voltage (LV) | Safe for general building systems and marine equipment |

| Conductor Count | 3 Conductors | Supports three-phase power distribution in industrial and residential setups |

| Temperature Range | -20°C to +70°C | Operates reliably in coastal and subterranean environments |

Adjust conductor count or material composition to meet specific current load requirements. Modify jacket material (e.g., UV-resistant PE for outdoor use or chemical-resistant PVC for industrial zones) to align with environmental conditions.

Designed for marine and building applications, this cable combines durability and flexibility. The triple-conductor design ensures reliable power transmission in harsh underwater conditions and urban infrastructure. With XLPE insulation, you can achieve 30% higher temperature resistance than standard PVC, extending operational lifespan in extreme environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Insulation Resistance | 100 MOhms | +15% (115 MOhms) | +30% (130 MOhms)* |

| Tensile Strength | 1,500 N/m² | 1,725 N/m² | 1,950 N/m² |

| Temperature Range | -20°C to +70°C | -30°C to +80°C | -40°C to +90°C |

| Water Resistance | IPX7 (1m/30min) | IPX8 (3m/2hrs) | IPX8 (10m/24hrs)* |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model certifications include IEC 60092-358 for submarine cables and ASTM B26 for aluminum conductor purity.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Insulation Material | Marine environments with high humidity | Industry Standard: PVC (dielectric strength 4 kV/mm) Our Base: PE (6 kV/mm ▲) Our Advanced: XLPE (8 kV/mm ▲▲▲) | ▲▲▲ XLPE withstands higher voltage surges (e.g., 3 kV vs industry 1 kV) Enhanced durability in saltwater | XLPE increases material cost by ~25% compared to PVC |

| Conductor Material | High-current offshore platforms | Industry: Aluminum (conductivity 37% IACS) Our Base: Copper-clad Al (55% IACS ▲) Our Advanced: Pure Cu (100% IACS ▲▲▲) | ▲▲▲ Copper reduces energy loss by 40% over aluminum in long runs | Pure copper adds 30% more weight, complicating installation |

| Jacket Material | Rocky seabed installations | Industry: PVC (abrasion resistance 150 N) Our Base: PE (200 N ▲) Our Advanced: Composite (300 N ▲▲▲) | ▲▲▲ Composite resists abrasion from coral reefs (300 N vs industry 150 N) | Requires specialized cutting tools during installation |

| Voltage Rating | Long-distance marine power grids | Industry: 0.6/1 kV Our Base: 1/1.2 kV ▲ Our Advanced: 1.8/3 kV ▲▲▲ | ▲▲▲ Supports 3 kV transmission (vs industry 1 kV), reducing energy loss | Thicker insulation increases cable diameter by 20% |

| Flexibility | Tight underwater conduits | Industry: Stiffness >50 N (ASTM D1319) Our Base: 35 N ▲ Our Advanced: 20 N ▲▲▲ | ▲▲▲ Easier to bend in narrow trenches (20 N vs industry 50 N) | Softer materials may require external support in dynamic zones |

| Chemical Resistance | Chemical plant offshore sites | Industry: 10 chemicals (ASTM D543) Our Base: 20 chemicals ▲ Our Advanced: 30+ chemicals ▲▲▲ | ▲▲▲ Withstands 30+ chemicals (e.g., acids, solvents) for refinery use | Enhanced coatings add 15% to production time |

⭐⭐⭐⭐⭐ Captain Elena Vasquez - Offshore Platform Engineer

"We installed the Pro Model on our North Sea platform six months ago, and it’s performed flawlessly. The XLPE insulation and copper-aluminum hybrid conductors have handled temperature swings and saltwater exposure without issue. Installation was simplified thanks to the color-coded wiring—no confusion during complex hookups."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ David Lin - Electrical Project Manager, High-Rise Development

"Used the Advanced Model across two high-rise builds. The -30°C to +80°C rating gave us peace of mind during winter pours and summer rooftop work. The IPX8 waterproofing held up even during unexpected downpours before encasement. Plus, the lighter aluminum content made overhead pulls significantly easier than traditional all-copper cables."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Thomas Reed - Subsea Cable Installer

"Deployed the Pro Model for a coastal interconnection project at 8m depth. The composite PE/PVC jacket resisted abrasion from rocky seabed better than expected. Only reason it’s not five stars is that the increased diameter (due to triple-layer insulation) required slight conduit adjustments. But the 30+ chemical resistance is no exaggeration—held up near a wastewater outflow zone with no degradation."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Plant Maintenance Supervisor

"We replaced aging PVC-insulated cables in our chemical processing wing with the Advanced Model. After seven months of continuous operation in a high-humidity, mildly corrosive environment, zero insulation breakdowns. The 115 MOhms insulation resistance is clearly making a difference in reducing leakage currents. Easy to inspect thanks to the color-coded cores."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ James Carter - Naval Architect, Yacht Refit Specialist

"Used the Base Model for a luxury vessel’s power distribution retrofit. Needed something lightweight but reliable—this delivered. The hybrid conductor design cut weight by nearly 20% versus copper-only alternatives, which matters for balance and fuel efficiency. Flexible enough to route through tight bulkheads, and the UV-resistant PE outer layer has held up beautifully on deck runs."Purchase Date: September 2024 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Offshore Energy Infrastructure Consultant

"In my 15 years evaluating submarine cables, this product stands out for its smart material integration. The copper-aluminum hybrid isn’t a cost-cutting gimmick—it’s an engineered balance that reduces weight without sacrificing conductivity. For projects under 3 kV, especially in mixed terrestrial-marine layouts, I recommend the Advanced or Pro models for their superior thermal and chemical resilience."

Linda Park - Senior Electrical Designer, Urban Infrastructure Group

"For high-density commercial buildings where cable runs are long and environmental control is critical, this cable’s XLPE insulation and 1.2 kV rating offer a tangible upgrade over standard PVC. I’ve specified the Advanced Model in three recent projects—its -30°C cold tolerance was essential for rooftop mechanical rooms in northern climates."

Posted: 5 days ago

"Used the Advanced Model for a seaside resort power feed. Withstood monsoon-level rain and salt spray. No moisture ingress detected after 3-month inspection. Will be our go-to for similar jobs."

Posted: 2 weeks ago

"Requested UV-optimized PE jacketing for aerial spans. Supplier delivered on time with full certification. Cable looks and performs like new after four months of sun exposure."

Posted: 3 weeks ago

"Thicker insulation took some getting used to when terminating, but once we adjusted tools, everything went smoothly. Performance has been rock solid since installation."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.